Automobile motor with long service life

A motor, long-life technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of shortening the service life of the motor, inconvenient disassembly of the motor, not meeting the needs of use, etc., to achieve easy separation and assembly, easy disassembly, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

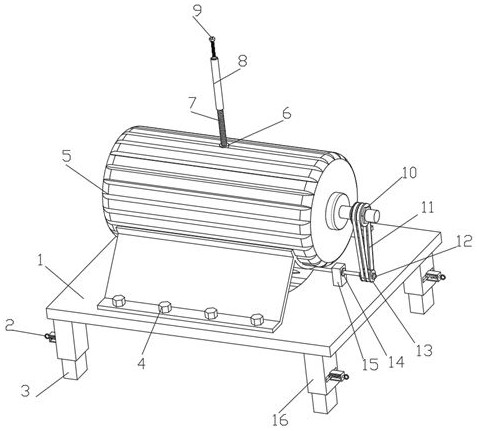

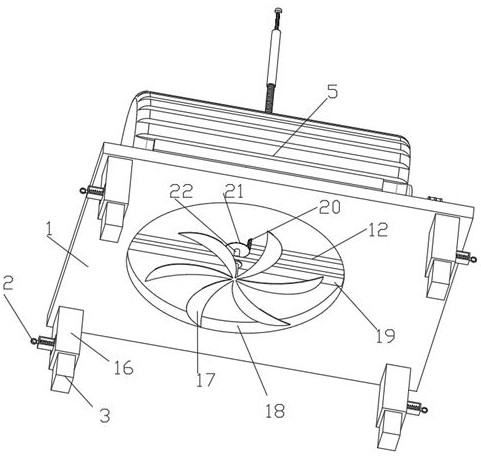

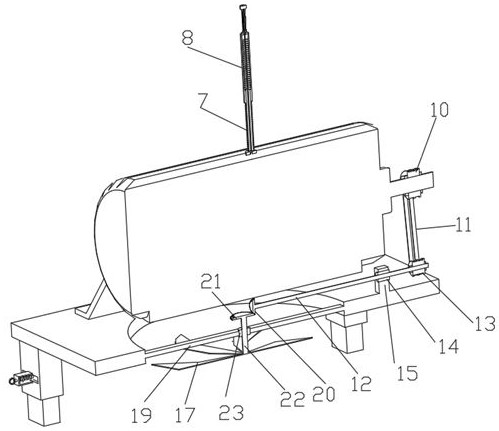

[0032] Such as Figure 1-5 An automotive motor with long service life is shown, including a base plate 1 and a motor 5. The bottom of the base plate 1 is symmetrically fixedly connected with a cover plate 16, and the inside of the cover plate 16 is connected with a support plate 3 through sliding holes, and the outer wall of the cover plate 16 A positioning structure 2 for positioning the support plate 3 is provided. A through hole 18 is provided on the top of the bottom plate 1. The inner wall of the through hole 18 is fixedly connected with a second support plate 19, and the second support plate 19 is connected with a second rotation rod 22. The second rotation The top of the rod 22 is fixedly connected with a driven bevel gear 21, the bottom of the second rotating rod 22 is uniformly fixedly connected with a fan blade 17 for driving air flow along the circumferential direction, and the output end of the motor 5 is fixedly connected with a driving pulley 10. Pulley 10 is mov...

Embodiment 2

[0034] Embodiment 2 is a further improvement to Embodiment 1.

[0035] Such as Figure 1-5A long-life automobile motor shown includes a base plate 1 and a motor 5. The bottom of the base plate 1 is symmetrically fixedly connected with a cover plate 16, and the cover plate 16 is connected with a support plate 3 through sliding holes, and the cover plate 16 is slidably connected. The outer wall is provided with a positioning structure 2 for the positioning of the support plate 3. The positioning structure 2 includes a pull ring 201, a U-shaped plate 202, a wedge block 203, a wedge-shaped groove 204, a slide bar 205, a first spring 206 and a chute 207, and the U-shaped plate 202 is fitted and slidably connected with a slide bar 205 through the slide hole, the outer end of the slide bar 205 is fixedly connected with a pull ring 201 for pulling the slide bar 205, and the inner end of the slide bar 205 is fixedly connected with a wedge-shaped block 203 with the hypotenuse facing dow...

Embodiment 3

[0037] Embodiment 3 is a further improvement to Embodiment 1.

[0038] Such as Figure 1-5 A long-life automobile motor shown includes a base plate 1 and a motor 5. The bottom of the base plate 1 is symmetrically fixedly connected with a cover plate 16, and the cover plate 16 is connected with a support plate 3 through sliding holes, and the cover plate 16 is slidably connected. The outer wall is provided with a positioning structure 2 for the positioning of the support plate 3, and the top of the bottom plate 1 is provided with a through hole 18, and the inner wall of the through hole 18 is fixedly connected with a second support plate 19, and the second support plate 19 is connected with a second rotating rod 22. The top of the rotating rod 22 is fixedly connected with the driven bevel gear 21, the bottom of the second rotating rod 22 is uniformly fixedly connected with the fan blade 17 for driving air flow along the circumferential direction, and the output end of the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com