Self-adaptive material arranging and receiving auxiliary device for plastic basin injection molding processing

A technology for injection molding and auxiliary devices, applied in the field of injection molding, can solve problems such as low efficiency, reduced injection quality, product surface depression, etc., to avoid burns, avoid free fall, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

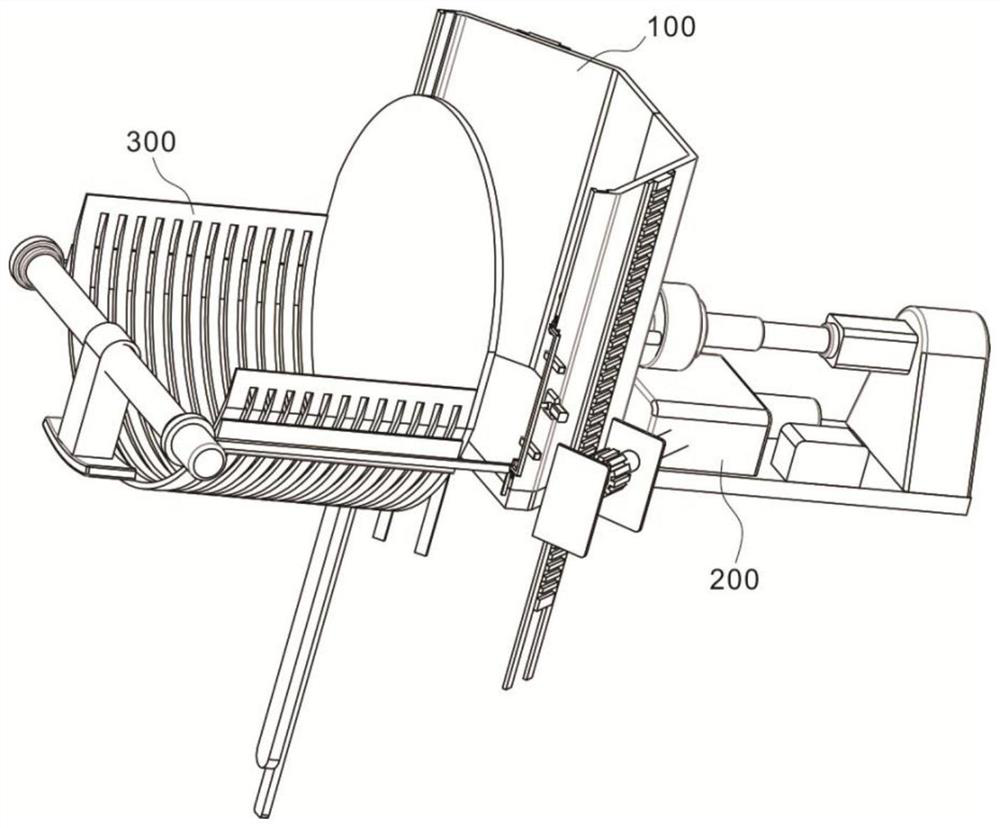

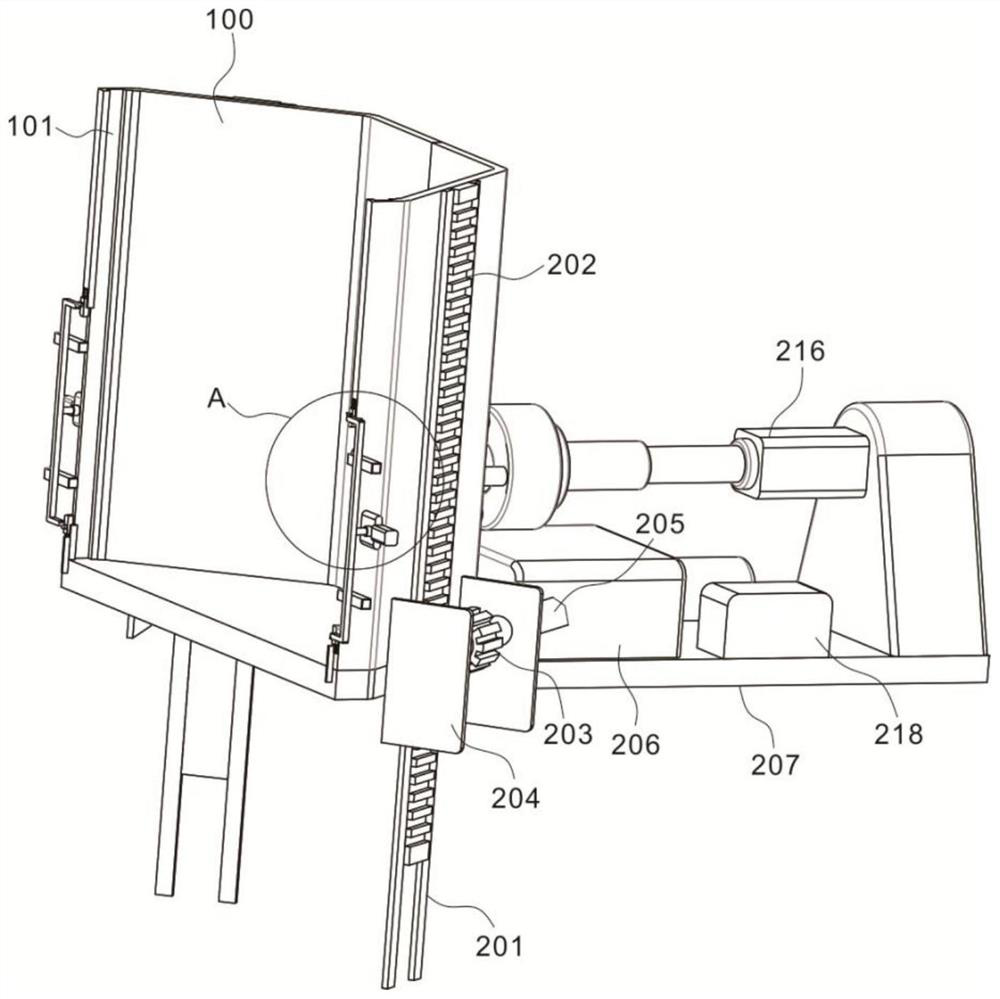

[0024] Example 1: Please refer to figure 1 and Figure 4 , the present invention provides an auxiliary device for adaptively arranging and receiving materials for injection molding of plastic pots, including a guide assembly, including a guide frame 100, the cross section of the guide frame 100 is an open concave structure, and the inner wall of the guide frame 100 is provided with symmetrical vertical guides. groove 101, and the bottom of the guide frame 100 is provided with a supporting plate 102, and the surface of the guide frame 100 is provided with a circular through opening 103; The tooth plate 202 is fixed on the surface of the guide frame 100 ;

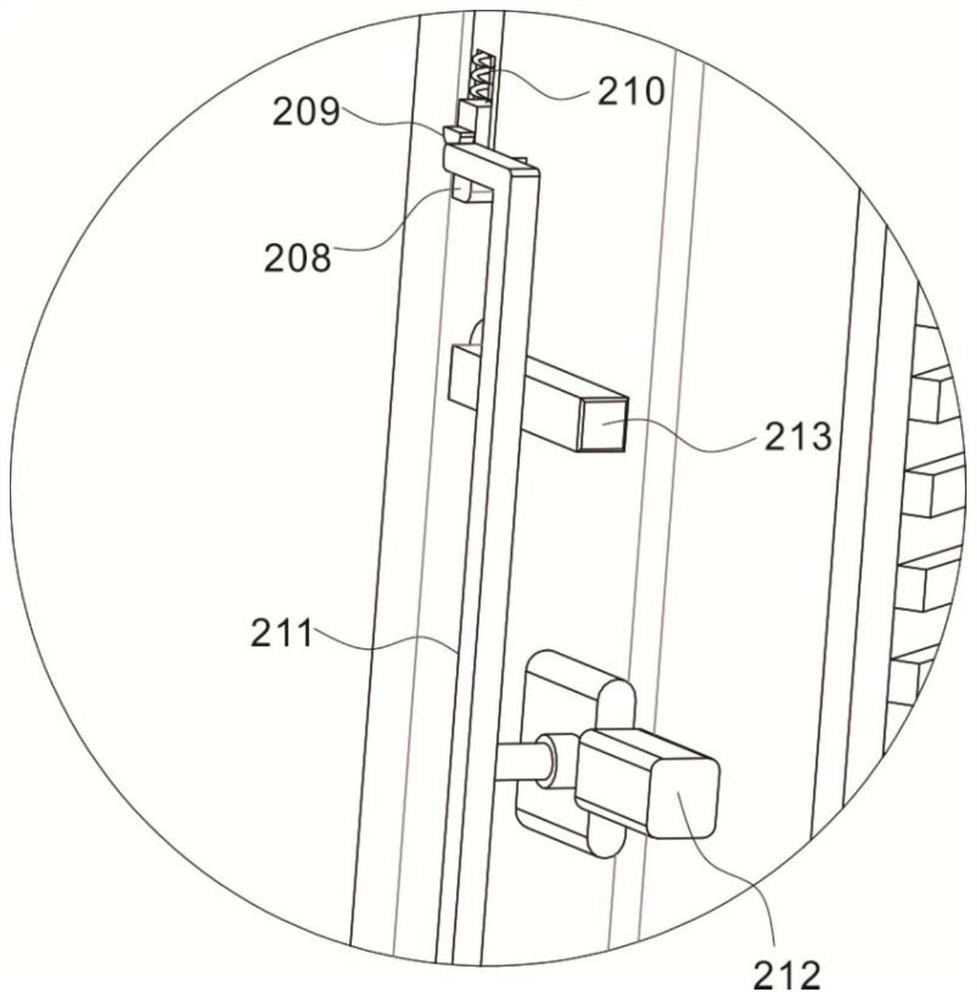

[0025] see figure 2 and image 3 , the gear plate 202 is meshed with the driving gear 203 and is connected to the driving gear 203. The driving gear 203 is plugged with a rotating shaft 205. One end of the rotating shaft 205 is plugged into the mounting plate 204, and the other end of the rotating shaft 205 is plugged int...

Embodiment 2

[0029] Example 2: Please refer to figure 1 and Figure 5The discharge assembly 300 includes a fixed support rod 301 fixedly connected to the surface of the guide frame 100 and symmetrically arranged. The end of the fixed support rod 301 is movably inserted with a rotating rod 302. The rotating rod 302 is driven to rotate by a stepping motor 303 and pushed to the The plastic basins on the bracket 305 are stacked on top of each other. After they are stacked to a suitable number, the tray 308 is driven to move up, the end of the bracket 305 is blocked, and the bracket 305 is driven to rotate downward. The plastic basin is supported by the tray 308. Then, the stacked plastic basins can be taken out manually, and the surface of the rotating rod 302 is fixedly connected with the bracket 305 through the linkage block 304, and the bracket 305 is in an arc-shaped plate structure.

[0030] The surface of the bracket 305 is provided with a sliding piece 306 which is slidingly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com