Metal nut hot embedding equipment for plastic product

A technology for plastic products and nuts, which is applied in the field of metal nut hot embedding equipment for plastic products, and can solve the problems of being unable to fix and clamp plastic products of different sizes, unable to collect metal nuts in time, unable to fix and heat metal nuts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

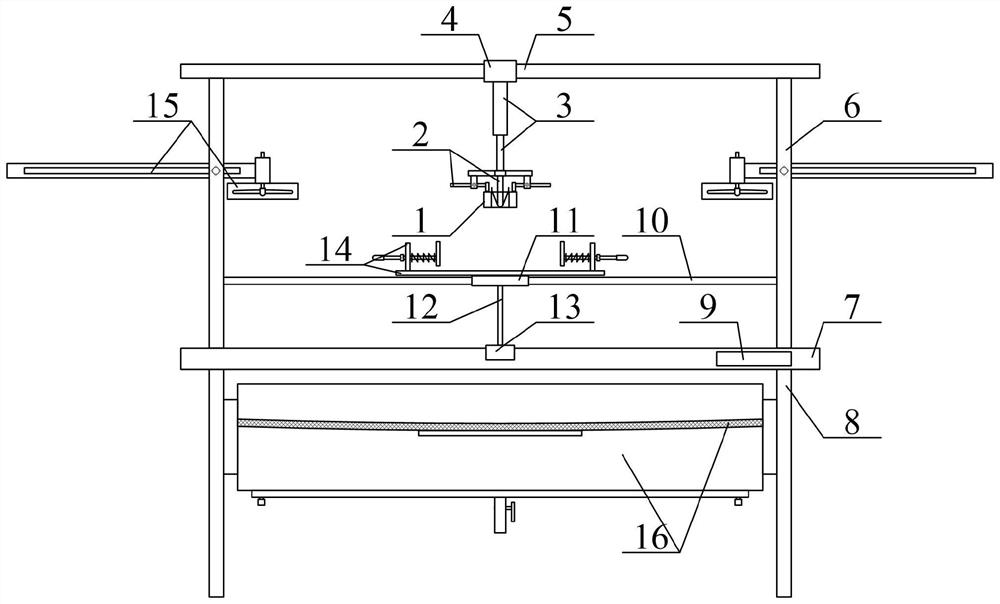

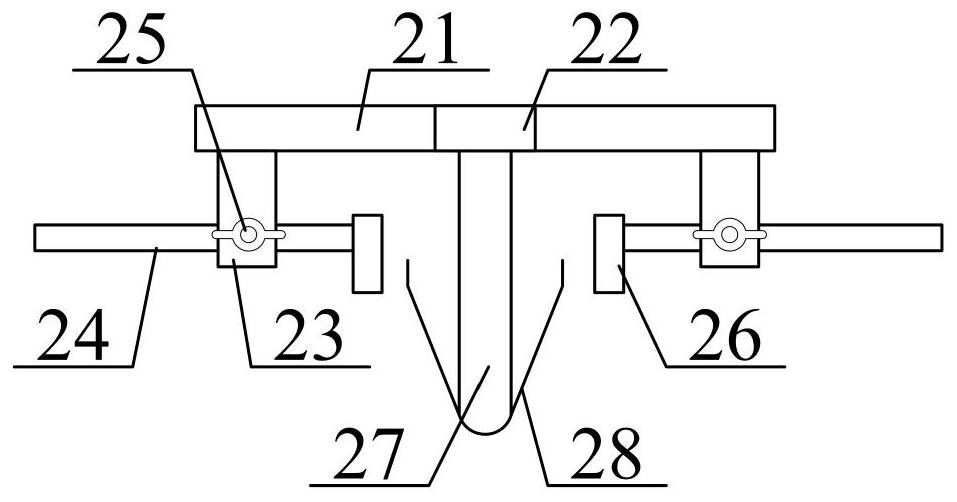

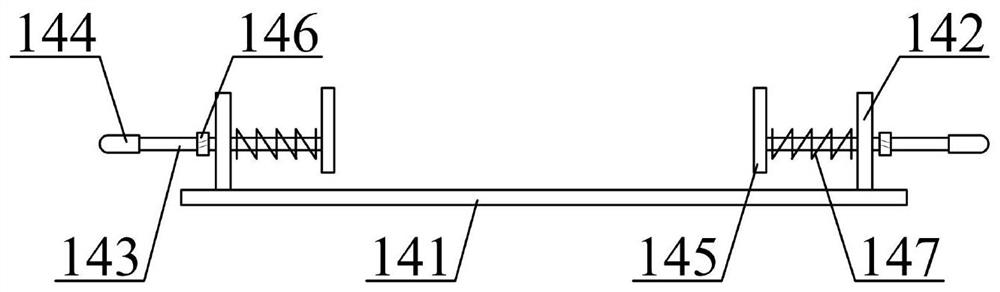

[0031] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown, a metal nut heat embedding equipment for plastic products includes a metal nut body 1, an adjustable electromagnetic heating heat embedding structure 2, a heat embedding telescopic rod 3, a return-shaped moving seat 4, a beam 5, a bracket 6, a machine Frame 7, outrigger 8, control panel 9, cross bar 10, moving sleeve 11, movable connecting rod 12, inverted U-shaped sliding seat 13, cushioning plastic clamping plate structure 14, adjustable heat-embedded rear cooling blade The structure 15 and the auxiliary hot-melt metal nut collection box structure 16, the metal nut body 1 is connected with the adjustable electromagnetic heating heat nest structure 2; the adjustable electromagnetic heating heat nest structure 2 and the heat nest The telescopic rods 3 are connected; the longitudinal upper end of the heat-embedded telescopic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com