Loop heat pipe

A loop heat pipe and pipeline technology, applied in circuits, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of loop heat pipe temperature fluctuations, pipeline blockage, evaporator drying and burning, etc., and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

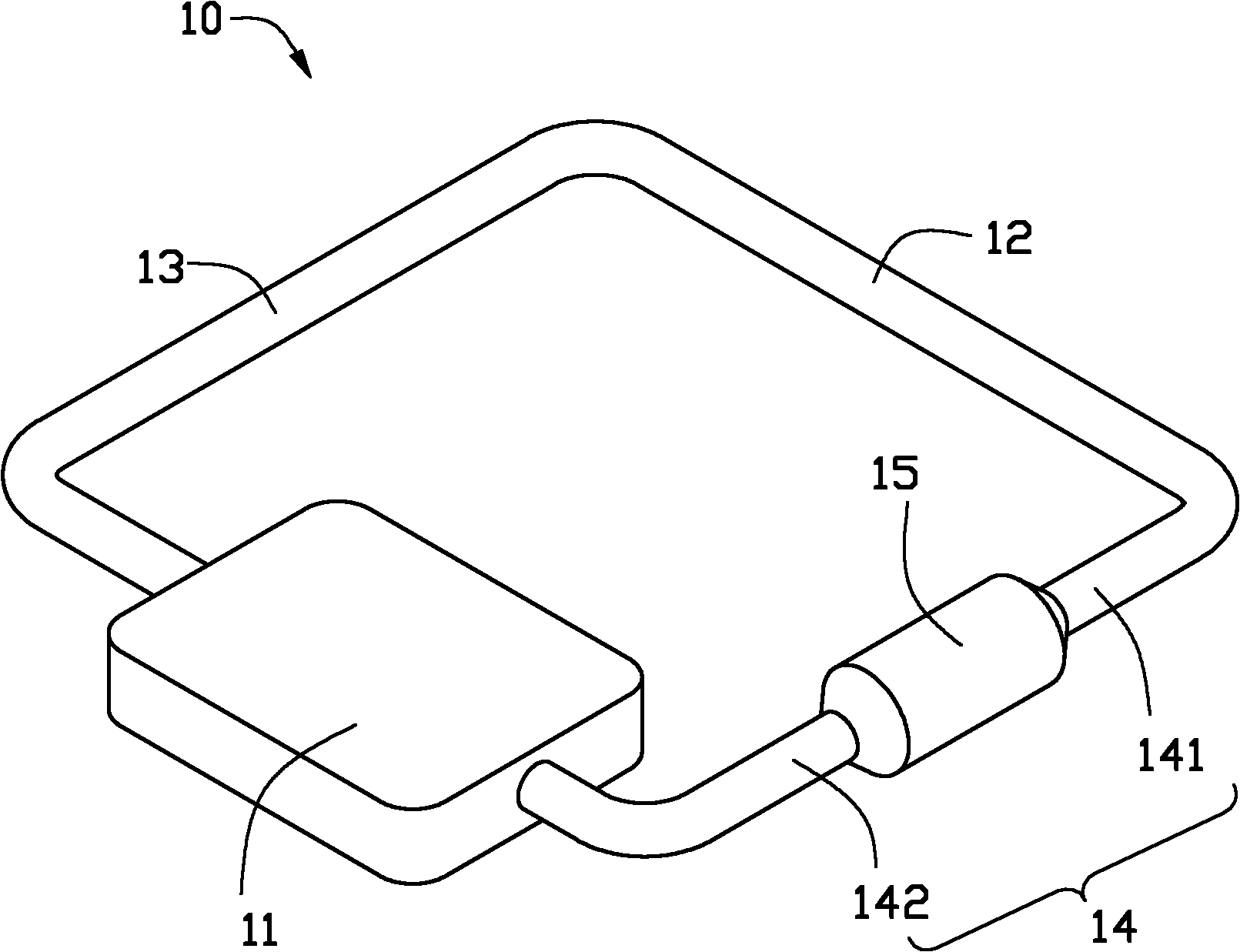

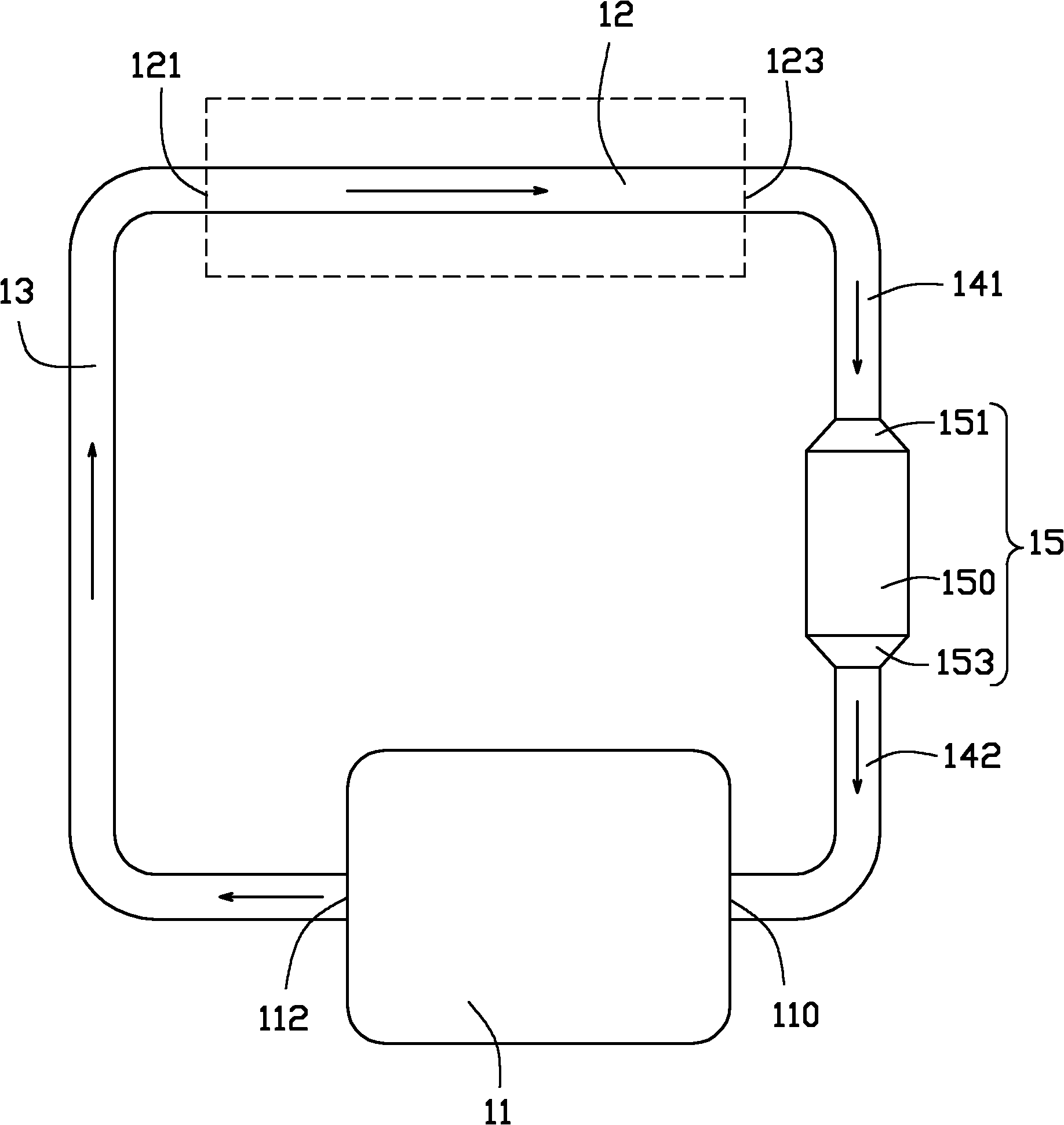

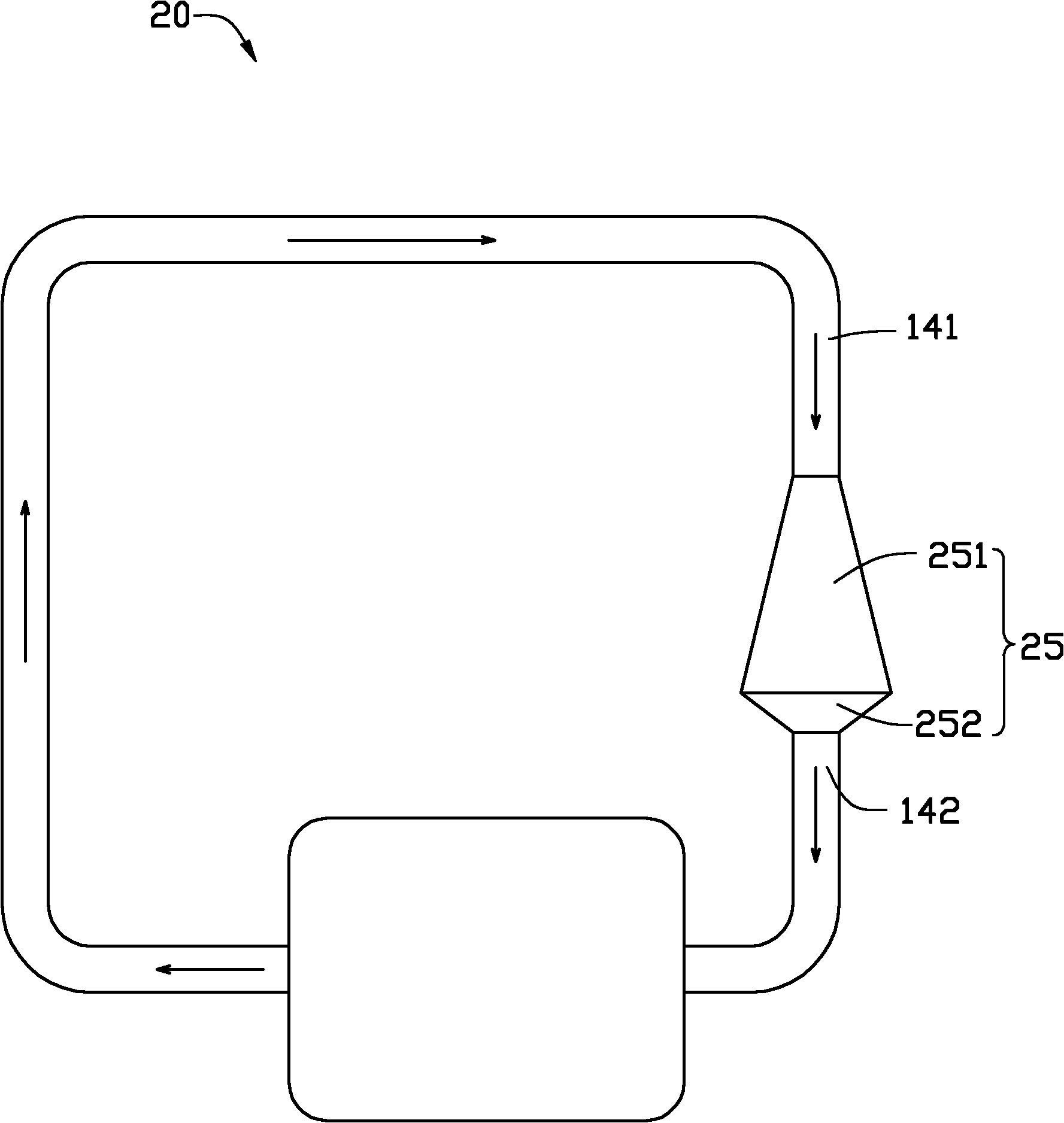

[0014] Please refer to figure 1 and figure 2 , The loop heat pipe 10 in the first embodiment of the present invention includes an evaporating part 11 , a condensing part 12 , a vapor pipeline 13 , a liquid pipeline 14 and a drip funnel part 15 .

[0015] The evaporator 11 is rectangular, and includes an evaporator inlet 110 connected to one end of the liquid line 14 and an evaporator outlet 112 connected to one end of the vapor line 13 . The evaporator 11 is thermally connected with a heat-generating electronic component, such as a CPU (not shown). The condensing part 12 is in the shape of a circular tube, which is parallel to the evaporating part 11 . The condenser 12 includes a condenser inlet 121 connected to the other end of the vapor pipeline 13 and a condenser outlet 123 connected to the other end of the liquid pipeline 14 . The outer surface of the condenser part 12 can be combined with a heat dissipation element, such as heat dissipation fins (not shown) pierced on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com