V-type air lift backflow two-stage sedimentation integrated sewage treatment tank

A sewage treatment tank, air lift and reflux technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. problems such as insufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

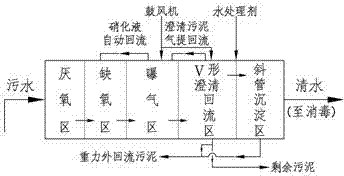

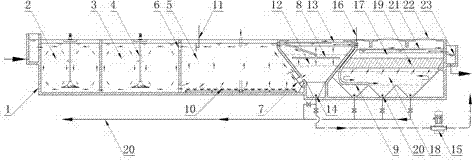

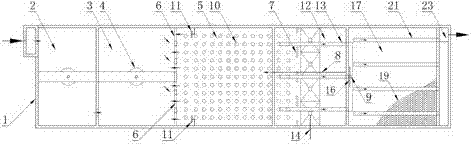

[0053] In the following, the present invention will be further described by referring to the accompanying drawings and using the V-type air-lift-reflux two-stage sedimentation integrated sewage treatment tank of the present invention as an example in conjunction with a sewage treatment project in a national key river basin.

[0054] Such as figure 1 As shown in the process flow diagram, the process flow of the V-type air-lifting-backflow two-stage sedimentation integrated sewage treatment tank of the present invention is simple and smooth, and nitrogen and phosphorus removal can be realized in the same pool, reaching the "Urban Wastewater Treatment Plant Pollutant Discharge Standard" required by the watershed "(GB18918-2002) Class A standard, and can run stably, the system does not have an internal return pump, nor an external return pump (the concentration of the external return sludge is high, and the sludge volume is small, directly borrowing the total influent sewage pump t...

Embodiment 2

[0083] A new urban district plans to build a new city sewage treatment plant for both industrial and domestic sewage. After water quality sampling analysis, it is considered that it is basically suitable to adopt a sewage treatment process that mainly uses biochemical treatment and supplemented by physical and chemical treatment. Discharge standard "(GB18918-2002) level B standard, the V-type gas lift reflux two-stage sedimentation integrated sewage treatment tank of the present invention is selected as the main structure of sewage treatment to achieve good results. The total planned sewage treatment capacity of the new district is 78,000 m 3 / d, divided into three phases of construction, the first phase will be built with 26,000 m 3 / d scale, that is, 2 blocks of 13,000 m 3 In addition to the V-type gas-lifting-backflow two-stage sedimentation integrated sewage treatment pool of / d, there is also an underground coarse grid and lifting pump room, an emergency pool for water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com