Annular spray evaporation device

A spray evaporation and annular technology, applied in the fields of rectification equipment, evaporation, concentration and distillation, can solve the problems of large energy consumption, increased equipment investment, poor safety, etc., and achieve the effects of good safety, capacity expansion, and convenient connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing 1- Figure 12 The features and principles of the present invention are described in detail, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

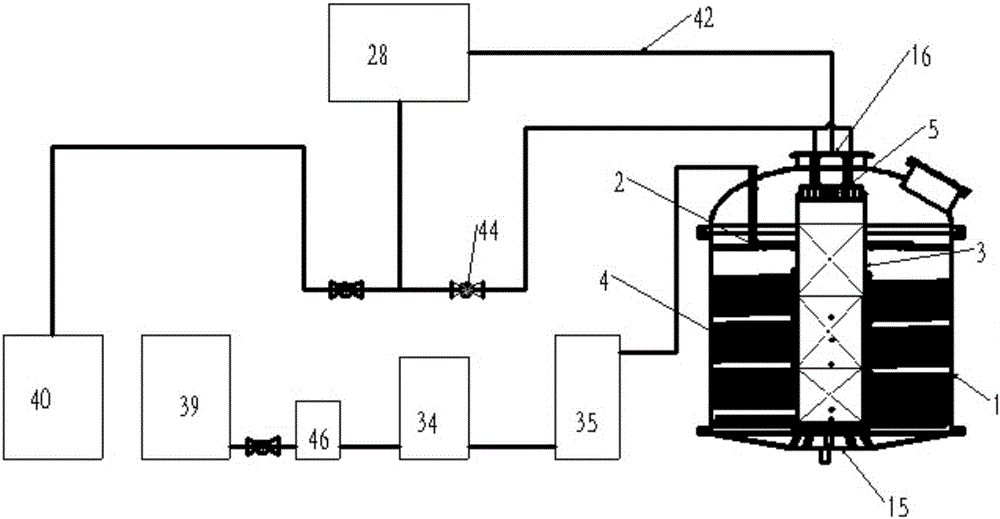

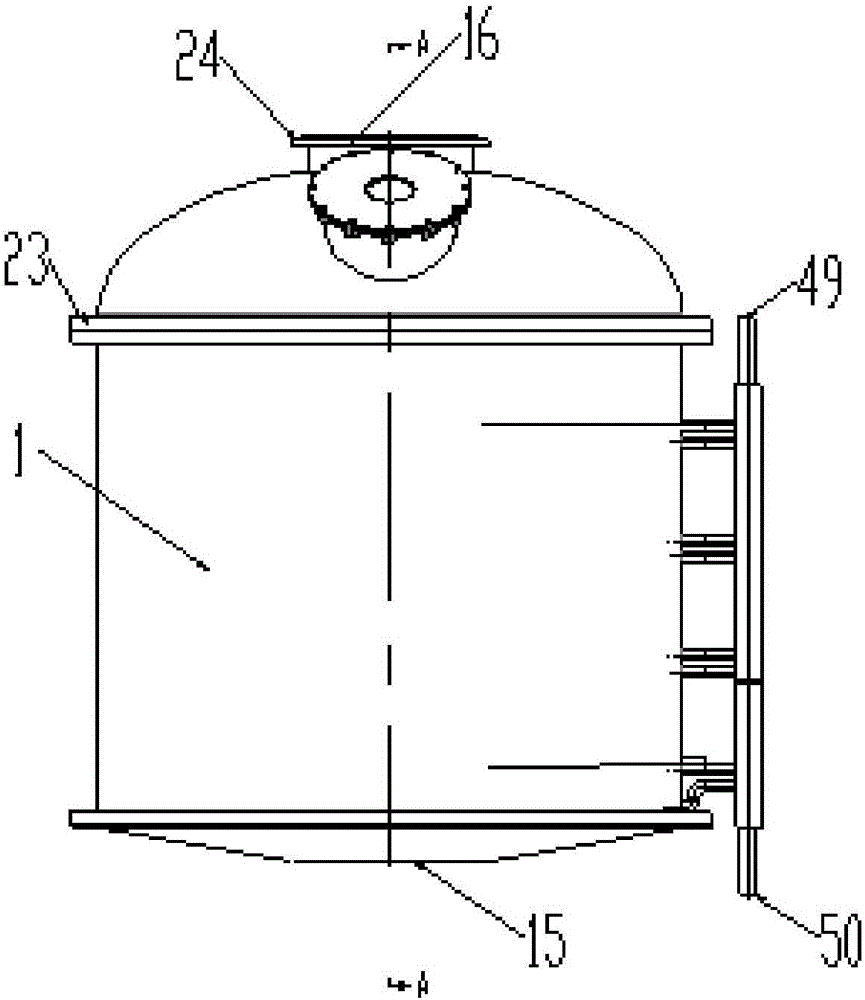

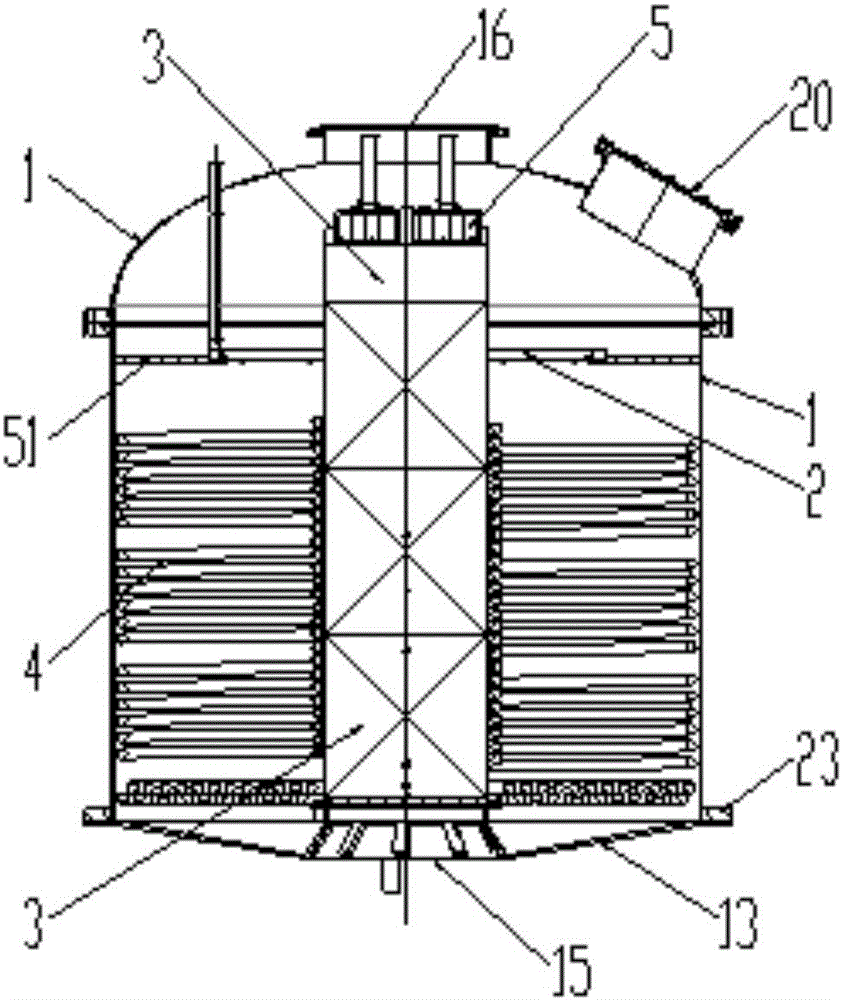

[0047]The invention includes a shell 1, in which are installed a ring atomizer 2, an insert packing cylinder 3, a U-shaped heating ring 4, and a vapor-liquid distribution plate 5, and the center of the shell 1 is fixed with an insert packing The cylinder 3 is fixed with a ring sprayer 2 on the upper part of the shell 1, and a number of U-shaped heating rings 4 are fixed in the shell 1 below the ring sprayer 2, and the upper part of the shell 1 has a low boiling point vapor phase outlet 16, the lower part has a high boiling point vapor phase outlet 15; the low boiling point outlet 16 is connected to the condenser 28 through the gas phase pipeline 42; the ring atomizer 2 is pressurized with the raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com