Temperature-resistant and salt-tolerant polymeric filtrate loss reducer for water-based drilling fluid and method for preparing temperature-resistant and salt-tolerant polymeric filtrate loss reducer

A quaternary copolymer and initiator technology, which is applied in the field of zwitterionic polymer fluid loss reducer and its preparation, can solve the problems of aggravated molecular thermal motion, aggravated failure of fluid loss reducer, high viscosity of drilling fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

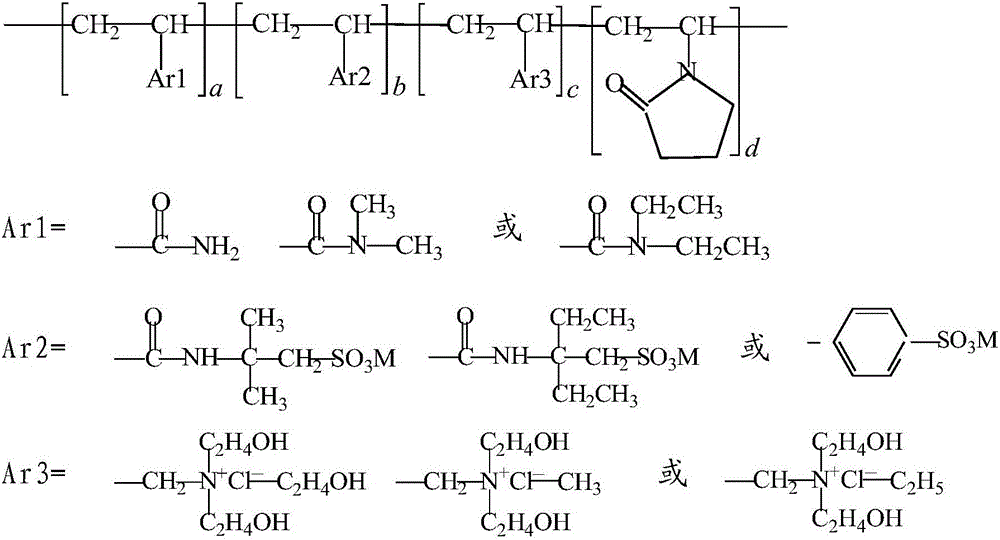

[0033] Embodiment 1: Preparation of fluid loss reducer PTS-1

[0034] Dissolve 2-acrylamido-2-methylpropanesulfonic acid (AMPS) in deionized water, neutralize the solution to pH=7~8 with NaOH, and N,N-dimethylacrylamide (DMAA), Trihydroxyethylallyl ammonium chloride (TAAC) and N-vinylpyrrolidone (NVP) are mixed with the neutralized solution, and then added to a three-necked flask with a thermometer and a reflux device, stirred, nitrogen and oxygen exhausted. Gradually raise the temperature to 50°C, add 0.3% initiator ammonium persulfate-sodium bisulfite after passing nitrogen for 30 minutes, and the total monomer concentration is 20%, after reacting for 7 hours, wash the white gel-like product with absolute ethanol Fully wash, separate the precipitate, dry and pulverize at high temperature to obtain the fluid loss reducer PTS-1, and obtain the target product with a yield of 90.8%. The reaction formula is as follows:

[0035]

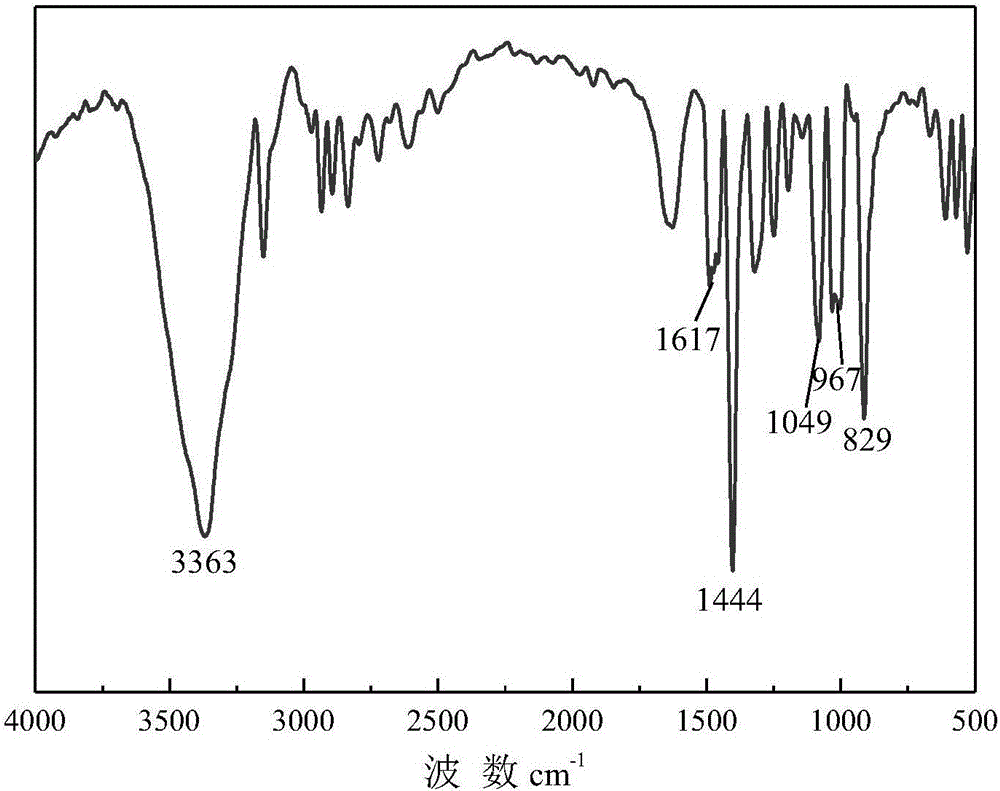

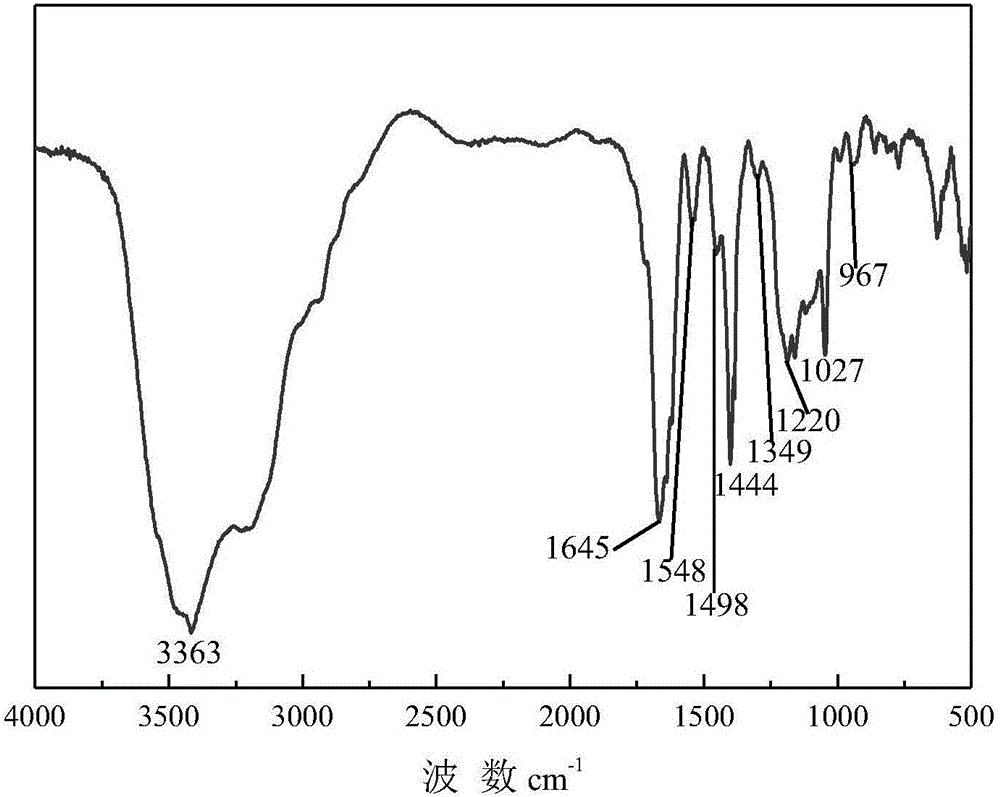

[0036] Structural characterization of fluid lo...

Embodiment 2

[0040] Embodiment 2: Preparation of fluid loss reducer PTS-2

[0041] Dissolve 2-acrylamido-2-methylpropanesulfonic acid (AMPS) in deionized water, neutralize the solution to pH=7~8 with NaOH, and N,N-dimethylacrylamide (DMAA), Methyldihydroxyethylallyl ammonium chloride (TMAC) and N-vinylpyrrolidone (NVP) are mixed with the neutralized solution, and then added to a three-necked flask with a thermometer and a reflux device, stirred, nitrogen and oxygen exhausted . Gradually raise the temperature to 50°C, add 0.3% initiator ammonium persulfate-sodium bisulfite after passing nitrogen for 30 minutes, and the total monomer concentration is 20%, after reacting for 7 hours, wash the white gel-like product with absolute ethanol Fully wash, separate the precipitate, dry and pulverize at high temperature to obtain the fluid loss reducer PTS-2, and obtain the target product with a yield of 91.4%. The reaction formula is as follows:

[0042]

Embodiment 3

[0043] Embodiment 3: Preparation of fluid loss reducer PTS-3

[0044]Dissolve 2-acrylamido-2-methylpropanesulfonic acid (AMPS) in deionized water, neutralize the solution to pH=7~8 with NaOH, and N,N-dimethylacrylamide (DMAA), Ethyl dihydroxyethyl allyl ammonium chloride (TEAC) and N-vinylpyrrolidone (NVP) are mixed with the neutralized solution, and then added to a three-necked flask with a thermometer and reflux device, stirred, nitrogen and oxygen exhausted . Gradually raise the temperature to 50°C, add 0.3% initiator ammonium persulfate-sodium bisulfite after passing nitrogen for 30 minutes, and the total monomer concentration is 20%, after reacting for 7 hours, wash the white gel-like product with absolute ethanol Fully wash, separate the precipitate, dry and pulverize at high temperature to obtain the fluid loss reducer PTS-3, and obtain the target product with a yield of 91.2%. The reaction formula is as follows:

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com