Drilling water based plugging agent and using method thereof

A plugging agent and water-based technology, applied in chemical instruments and methods, earthwork drilling, boreholes/well components, etc., can solve problems such as low pressure bearing capacity and limited pressure bearing capacity, and achieve the goal of improving pressure bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

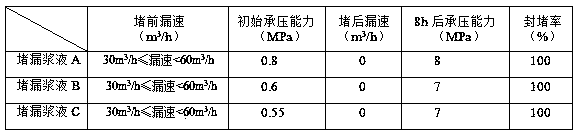

Examples

Embodiment 1

[0026] This embodiment proposes a water-based plugging agent for drilling. The plugging agent is made of solidified material, filling material, bridging material and suspension material in a mass ratio of 17:7:17:30, wherein the solidified material It is selected from limestone, the filling material is selected from diatomite, the bridging material is selected from a mixture of paper scraps and straw, and the suspending material is selected from cellulose modified microcrystalline fiber.

Embodiment 2

[0028] This embodiment proposes a water-based plugging agent for drilling. The plugging agent is made of solidified material, filling material, bridging material and suspension material in a mass ratio of 25:15:27:37, wherein the solidified material The filling material is selected from the mixture of diatomite, attapulgite and vermiculite, the bridging material is selected from the mixture of paper chips, bamboo chips and corncobs, and the suspending material is selected from the cellulose modified microcrystalline fiber.

Embodiment 3

[0030] This embodiment proposes a water-based plugging agent for drilling. The plugging agent is made of solidified material, filling material, bridging material and suspension material in a mass ratio of 18:12:27:32, wherein the solidified material It is selected from limestone and cement. Among the solidified materials, the mass ratio of limestone to cement is 12:5. The filling material is selected from a mixture of diatomaceous earth and vermiculite. The bridging material is selected from straw, bamboo chips, cotton fiber, corn A mixture of core and coconut shell powder, the suspending material is selected from cellulose modified microcrystalline fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com