Method for recycling Fenton iron mud

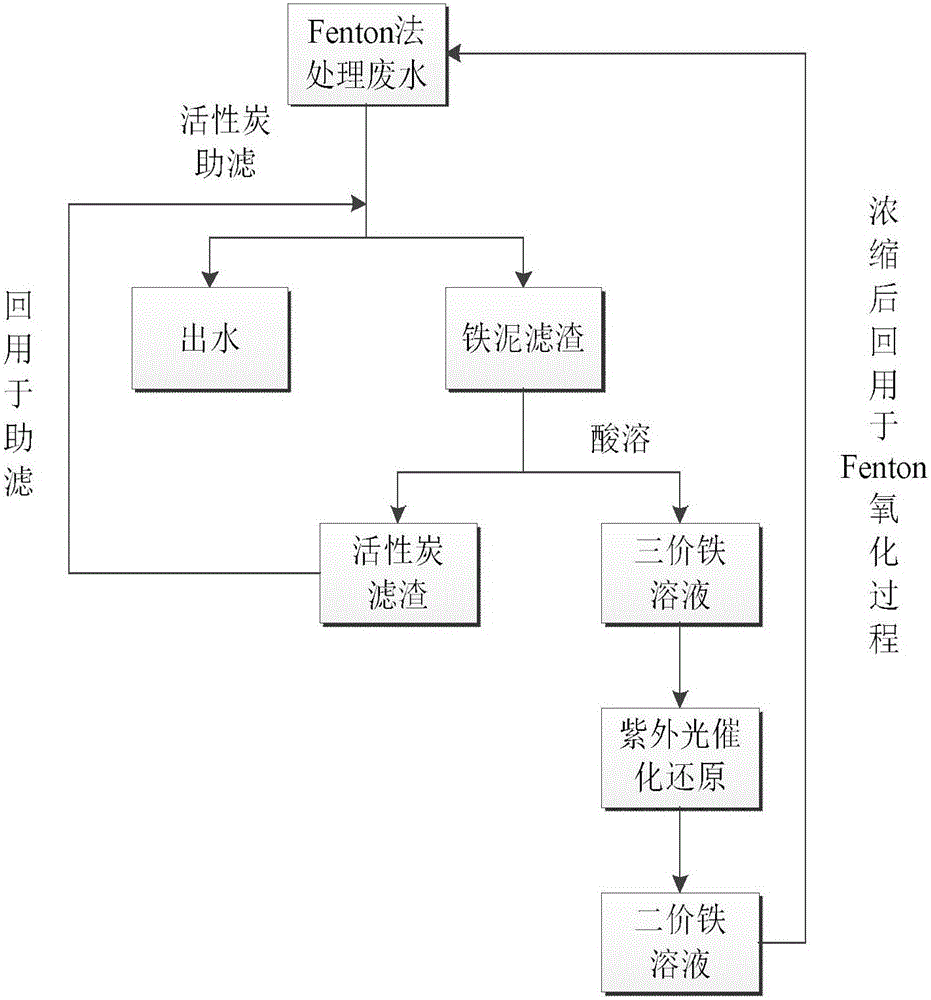

A technology of iron sludge and filter residue, which is applied in the field of solid waste resource treatment, can solve the problems of iron sludge secondary pollution, etc., and achieve the effects of reducing treatment costs, easy operation, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of p-nitroaniline wastewater, the wastewater mainly contains ammonium chloride, a small amount of ammonia water, which is alkaline, the organic matter is p-nitroaniline, nitrochlorobenzene and its derivatives, and the COD is about 7000mg / L.

[0025] Step 1, add 0.3% ferrous sulfate and 3% hydrogen peroxide (based on the quality of wastewater) to p-nitroaniline wastewater, stir and react at 40-50°C for 1 hour, then add 0.2% activated carbon, and continue at room temperature Stir and react for 0.5h, filter and separate to obtain water and iron slime filter residue;

[0026] Step 2, add 15% sulfuric acid solution to the iron slime filter residue obtained in step 1, stir and dissolve at 70°C for 1 hour, and separate by filtration to obtain Fe 3+ Solution and activated carbon filter residue, the activated carbon filter residue can be reused in step 1 to form the self-circulation of the activated carbon system;

[0027] The dosage of sulfuric acid is based on the iron...

Embodiment 2

[0031] A No. 60 red hydrolysis mother liquor, the organic matter after analysis is mainly brominated anthraquinone derivatives, a small amount of urotropine and decomposition products, and the COD is about 16000mg / L.

[0032] Step 1, add 0.5% ferrous sulfate and 4% hydrogen peroxide (based on the quality of wastewater) to p-nitroaniline wastewater, stir and react at about 50°C for 1 hour, then add 0.3% activated carbon, and continue to stir and react at room temperature 0.5h, filter and separate to get water and iron sludge filter residue;

[0033] Step 2, add 15% sulfuric acid solution to the iron slime filter residue obtained in step 1, stir and dissolve at 70°C for 1 hour, and separate by filtration to obtain Fe 3+ Solution and activated carbon filter residue, the activated carbon filter residue can be reused in step 1 to form the self-circulation of the activated carbon system;

[0034] The dosage of sulfuric acid is based on the iron content in the iron sludge, and the r...

Embodiment 3

[0038] A kind of medical waste water, the main components are NaCl, gluconate, ethyl acetate and some small molecule solvents, its COD is about 15000mg / L, and its pH is about 5.

[0039] Step 1, add 0.5% ferrous sulfate and 5% hydrogen peroxide (based on the quality of wastewater) to the wastewater, stir and react at about 50°C for 1 hour, then add 0.4% activated carbon, continue to stir and react for 0.5 hours at room temperature, filter Separated water and iron sludge filter residue;

[0040] Step 2, add 15% sulfuric acid solution to the iron slime filter residue obtained in step 1, stir and dissolve at 70°C for 1 hour, and separate by filtration to obtain Fe 3+ Solution and activated carbon filter residue, the activated carbon filter residue can be reused in step 1 to form the self-circulation of the activated carbon system;

[0041] The dosage of sulfuric acid is based on the iron content in the iron sludge, and the reaction formula is as follows:

[0042] 2Fe(OH) 3 +3H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com