Low fluorescent lubricating agent for drilling fluid and method for preparing low fluorescent lubricating agent

A lubricant and low-fluorescence technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as unfavorable industrial production, cumbersome preparation steps, complex polymerization process, etc., and improve environmental pollution problems and equipment conditions. Simple, easily biodegradable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

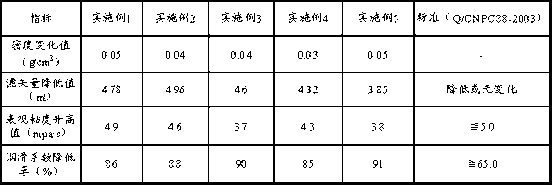

Examples

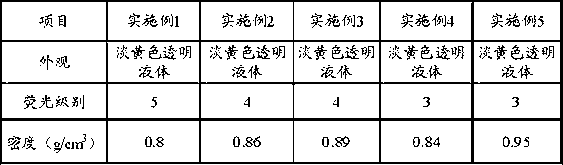

Embodiment 1

[0018] First, put 70kg of waste oil, 10kg of natural fatty acid, 10kg of vegetable oil, 5kg of oleic acid, 3kg of dodecylbenzenesulfonic acid, and 2kg of polyvinyl alcohol into the reaction kettle; then raise the temperature to 40°C and stir for 2 hours before discharging .

Embodiment 2

[0020] First, accurately weigh 65kg of waste oil, 18kg of natural fatty acid, 12kg of vegetable oil, 2kg of oleic acid, 1.5kg of dodecylbenzenesulfonic acid, and 1.5kg of polyvinyl alcohol into the reactor; then heat up to 50°C and stir for 1 hour Discharge.

Embodiment 3

[0022] First, accurately weigh 40kg of waste oil, 30kg of natural fatty acid, 16kg of vegetable oil, 10kg of oleic acid, 1kg of dodecylbenzenesulfonic acid, and 3kg of polyvinyl alcohol into the reactor; then heat up to 60°C and stir for 1.5 hours before discharging .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com