Method for preparing high-performance Y type molecular sieve film and application of the same in organic mixture separation

A molecular sieve, high-performance technology, applied in the direction of mercerized crystalline aluminum silicate zeolite, octahedral crystalline aluminum silicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problem that the support body is not suitable for industrial production, has no patent, and the result cannot be made people's satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

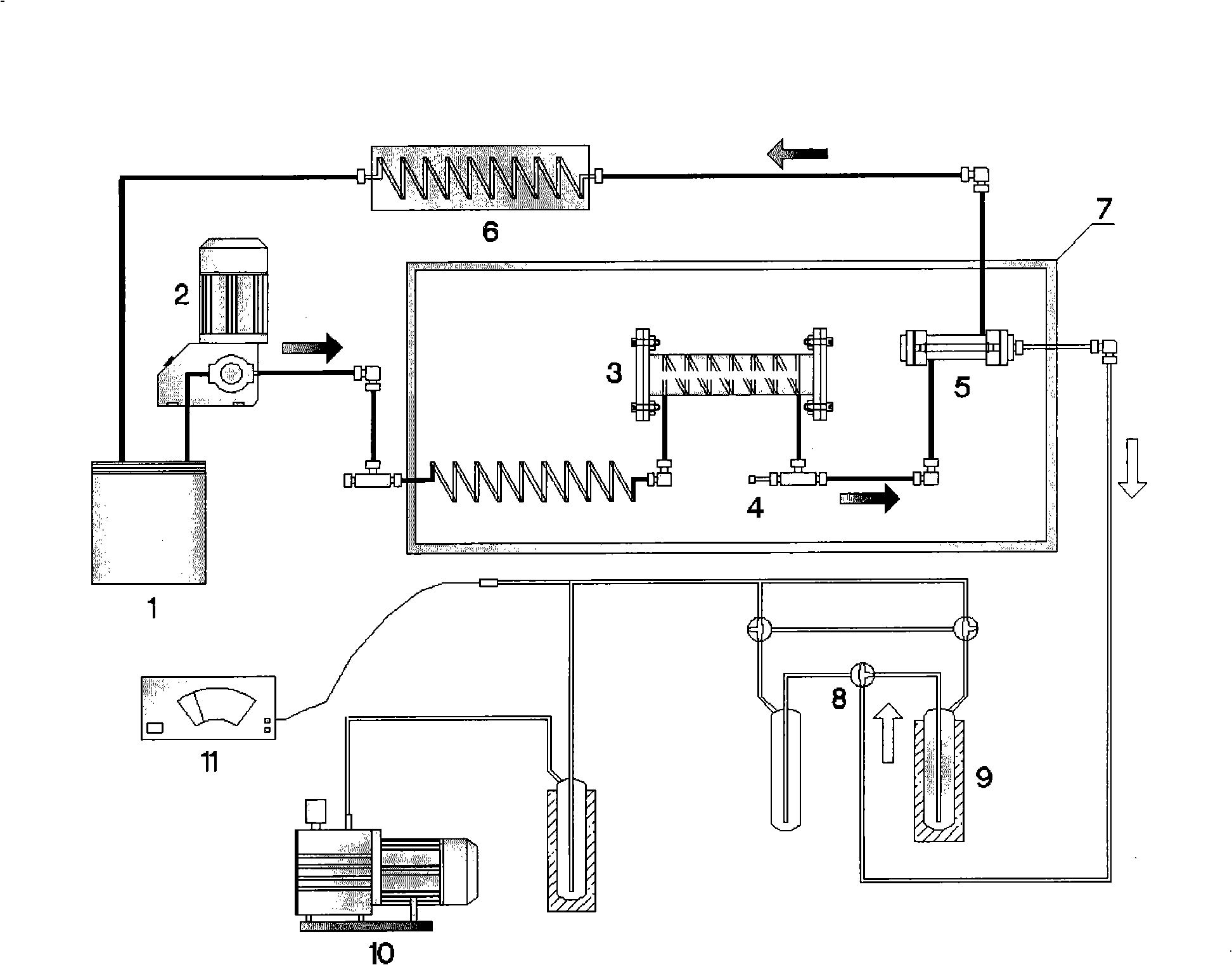

Method used

Image

Examples

Embodiment 1

[0043] Water glass with a modulus of 3.2 is used as the silicon source, aluminum hydroxide is used as the aluminum source, and sodium hydroxide and deionized water are used as raw materials for the synthesis liquid.

[0044] The porous mullite tube made by Nikkato Co., Ltd. of Japan is used as the substrate for membrane synthesis, and the mullite composition is 67wt% Al 2 o 3 and 33wt% SiO 2 . After the support body is polished with 800 mesh sandpaper and ultrasonically cleaned, a layer of NaY molecular sieve seed crystals is coated.

[0045] Dissolve aluminum hydroxide and sodium hydroxide in deionized water, add water glass under stirring conditions to form a molar ratio of 18Na 2 O: 1Al 2 o 3 : 20SiO2 2 : 1260H 2 O mixture, continue to stir for 2 hours sol. The sol was placed in a sealed polytetrafluoroethylene container and aged at room temperature for 12 hours. The aged sol is poured into a closed stainless steel reaction kettle, and the support body pre-coated w...

Embodiment 2

[0052] Synthesis ratio and preparation steps are the same as in Example 1. The difference is that the crystallization temperature is increased to 110°C. After the synthesized membrane was treated, the pervaporation performance of the membrane was investigated. The results are shown in Table 1.

Embodiment 3

[0054] Synthesis ratio and preparation steps are the same as in Example 1. The difference is that the crystallization temperature is increased to 120°C, and the synthesis time is reduced to 5 hours. After the synthesized membrane was treated, the pervaporation performance of the membrane was investigated. The results are shown in Table 1.

[0055] The supports before synthesis and the membrane tubes after synthesis were characterized by XRD and SEM instruments. XRD was XRD-6100 from Shimadzu, Japan, and SEM was JSM-6350 from JEOL.

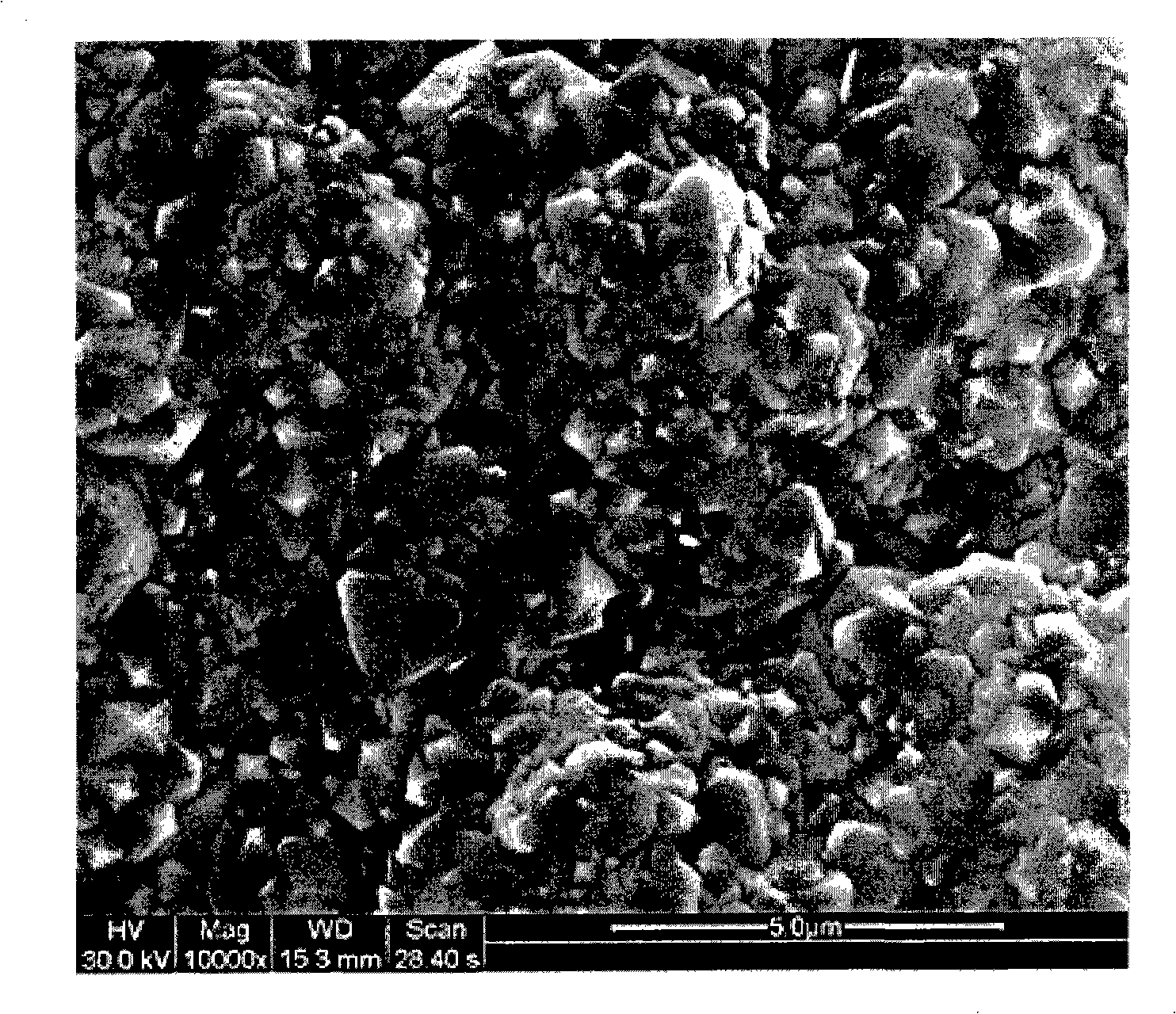

[0056] figure 2 The surface microstructure of NaY-type zeolite membranes synthesized on porous mullite supports is shown. The surface of the support is covered by a layer of NaY molecular sieve crystals, and the molecular sieve crystals are staggered and densely grown

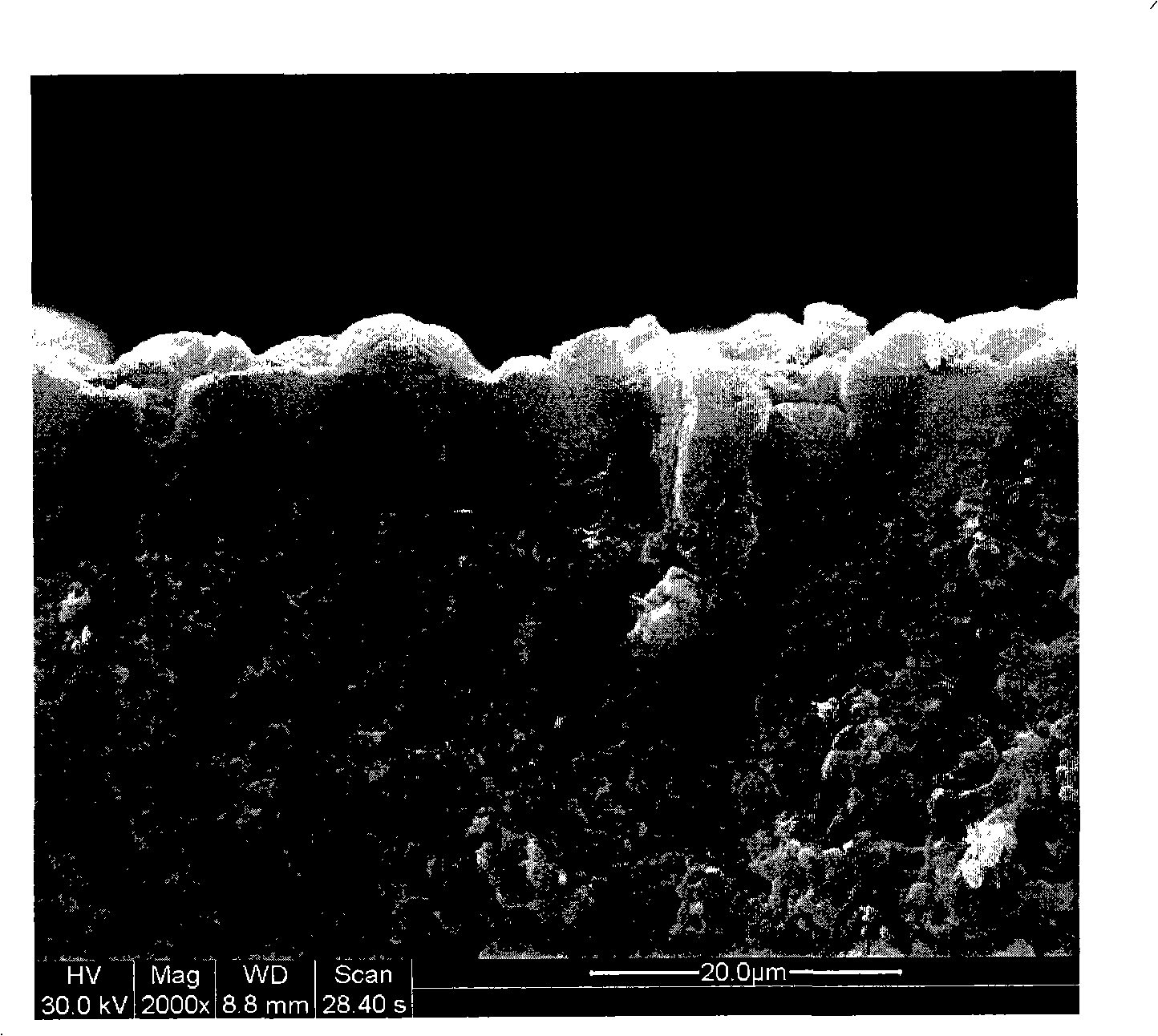

[0057] image 3 The cross-sectional morphology of the NaY-type zeolite membrane synthesized on the mullite support is shown. It can be seen from the figure that a continuous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com