Patents

Literature

30 results about "Ethyl tertiary-butyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

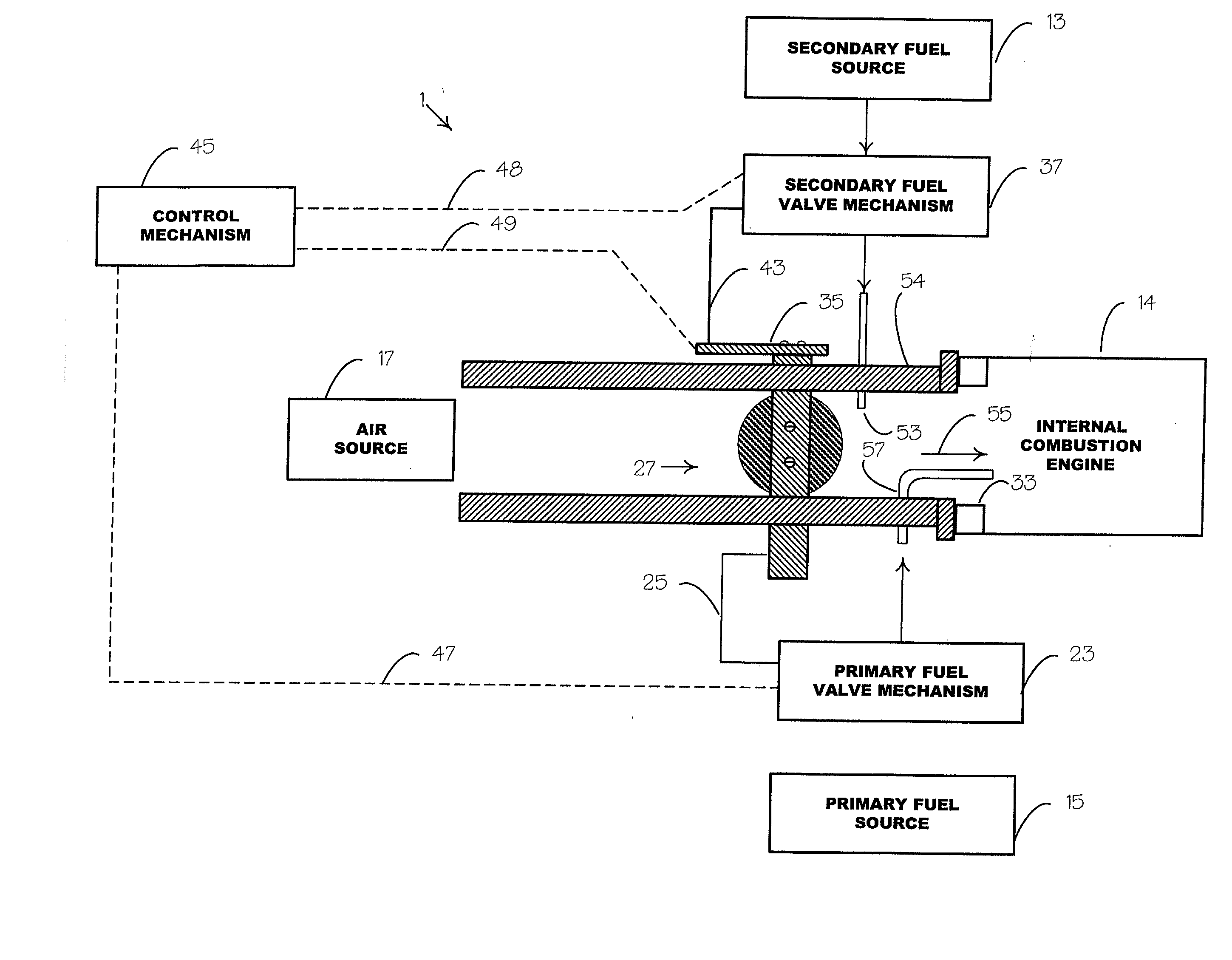

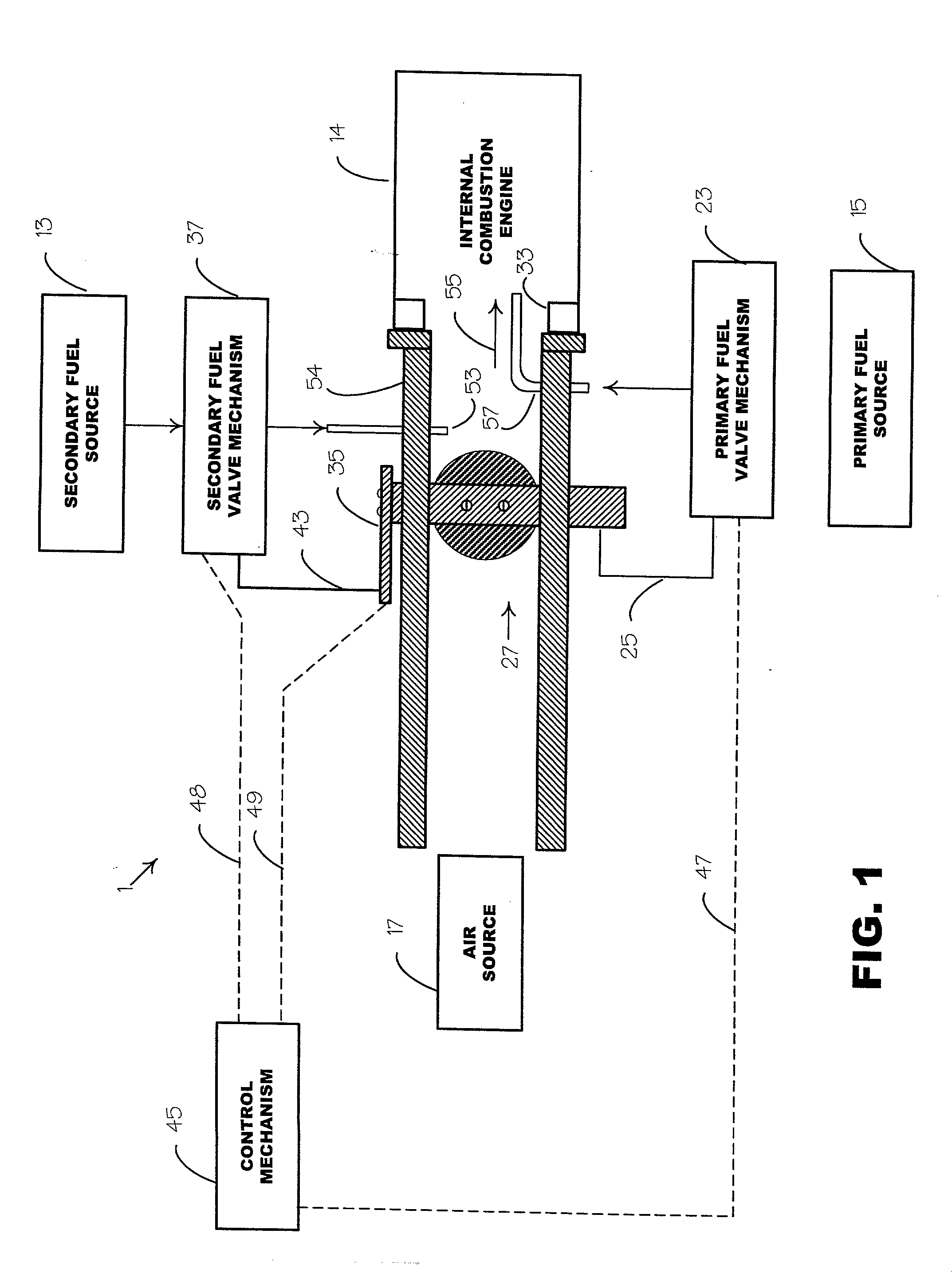

Internal combustion system adapted for use of a dual fuel composition including acetylene

InactiveUS20020014226A1Early ignition be preventEfficient in operationInternal combustion piston enginesNon-fuel substance addition to fuelChemistryFormate Esters

An internal combustion engine adapted to use an environmentally clean multi-fuel composition, comprising acetylene as a primary fuel and a combustible fuel, such as one or more fluids selected from an alcohol such as ethanol, methanol or any other alcohol or alcohols from the group comprising C1-C12 carbon chains, ethers such as from the group comprising dimethyl ether, diethyl ether, methyl t-butyl ether, ethyl t-butyl ether, t-amyl methyl ether, di-isopropyl ether and the like, low-molecular-weight esters such as from the group comprising methyl formate, methyl acetate, ethyl acetate, methyl propionate, ethyl propionate, ethyl malate, butyl malate, and the like, or other suitable combustible fluid such as mineral spirits and the like, as a secondary fuel for operatively preventing early ignition and knock arising from the primary fuel.

Owner:GOTEC

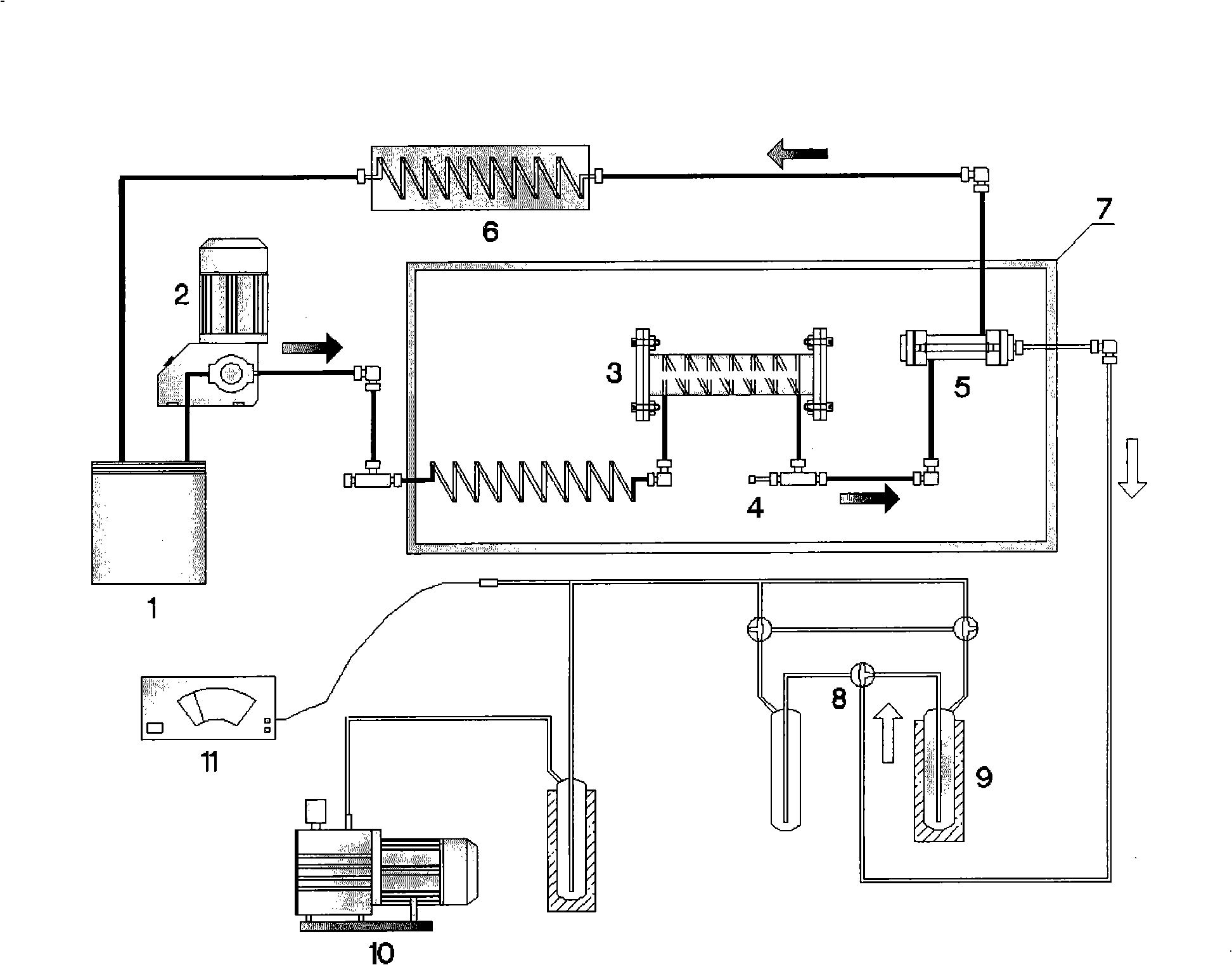

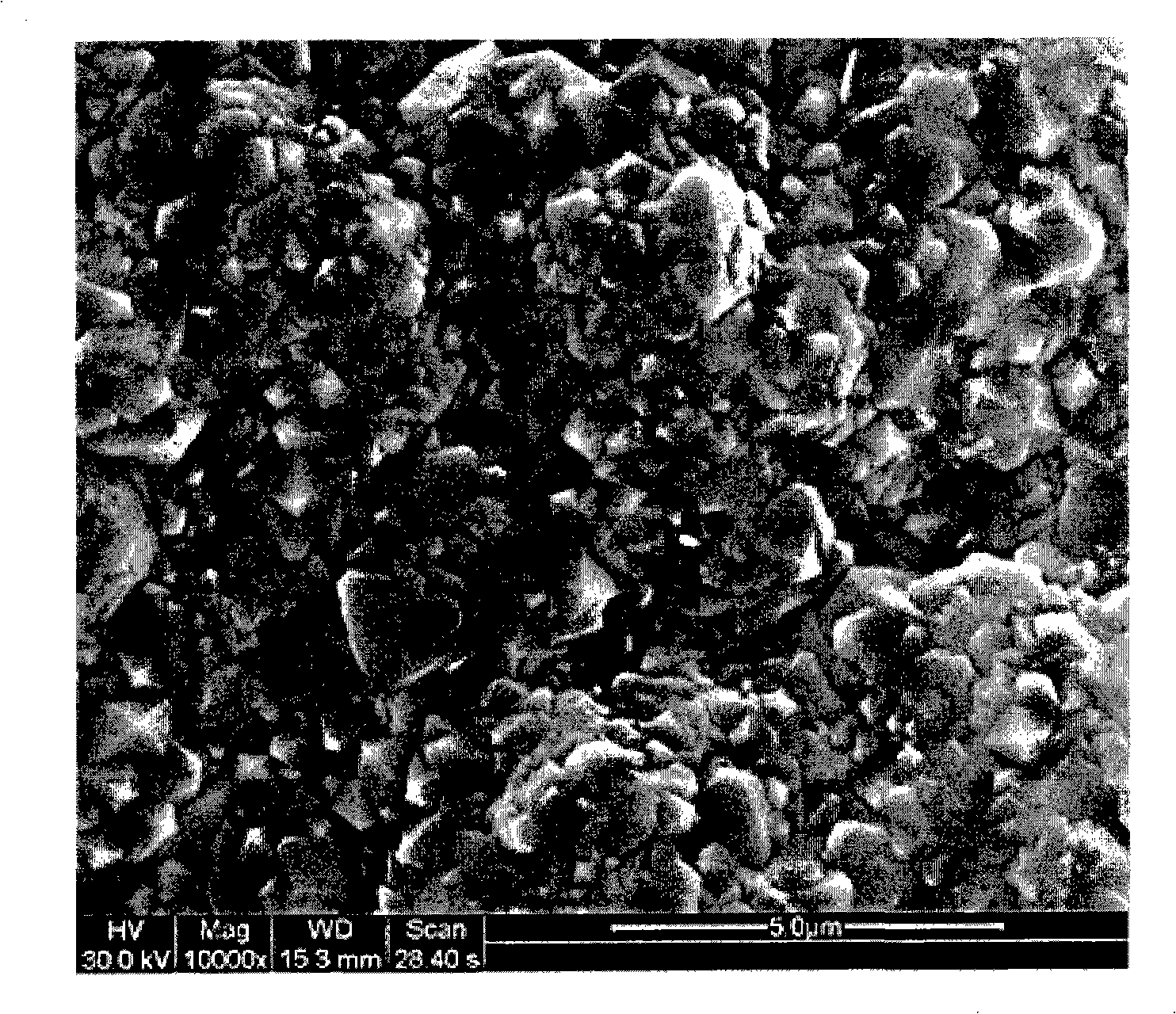

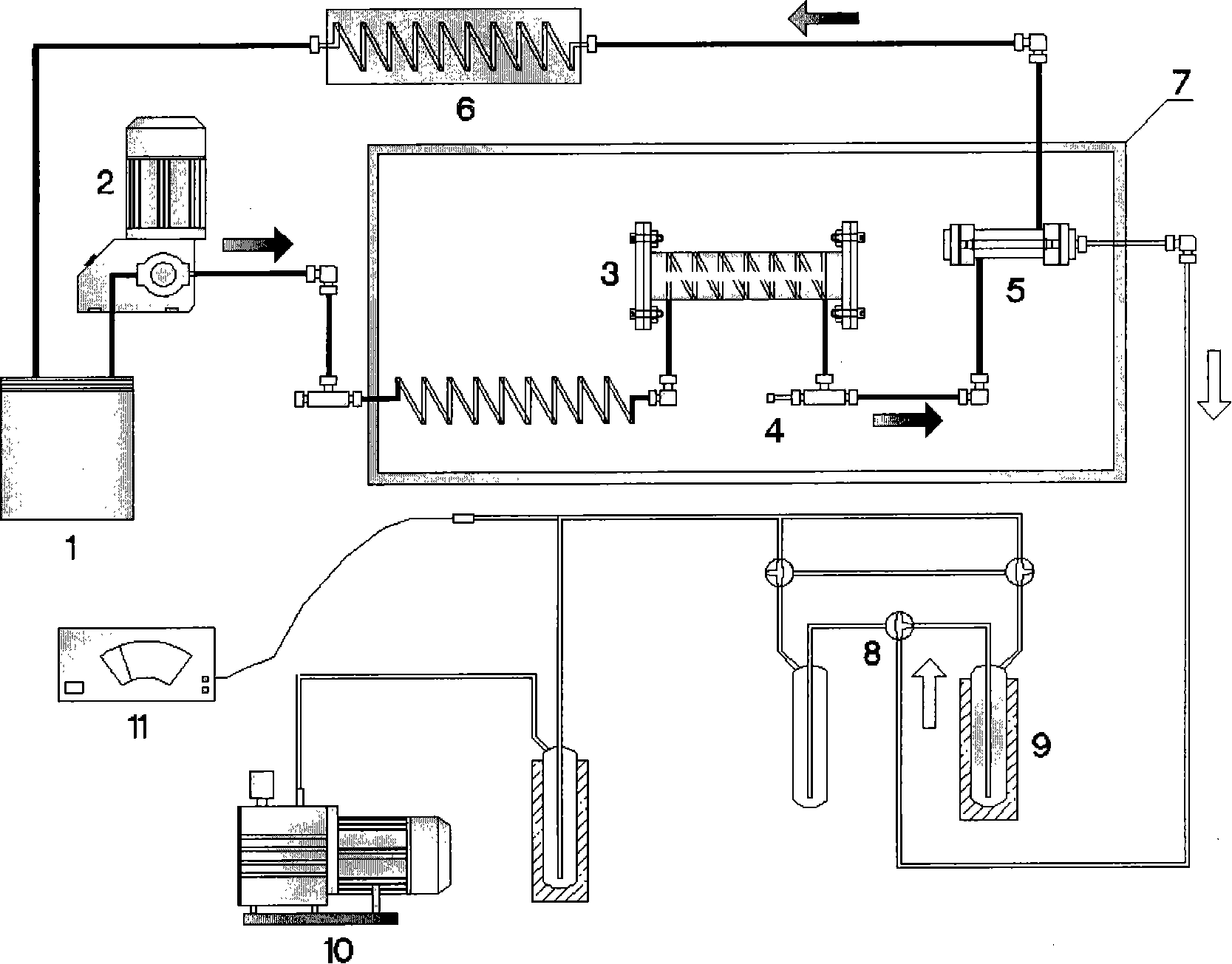

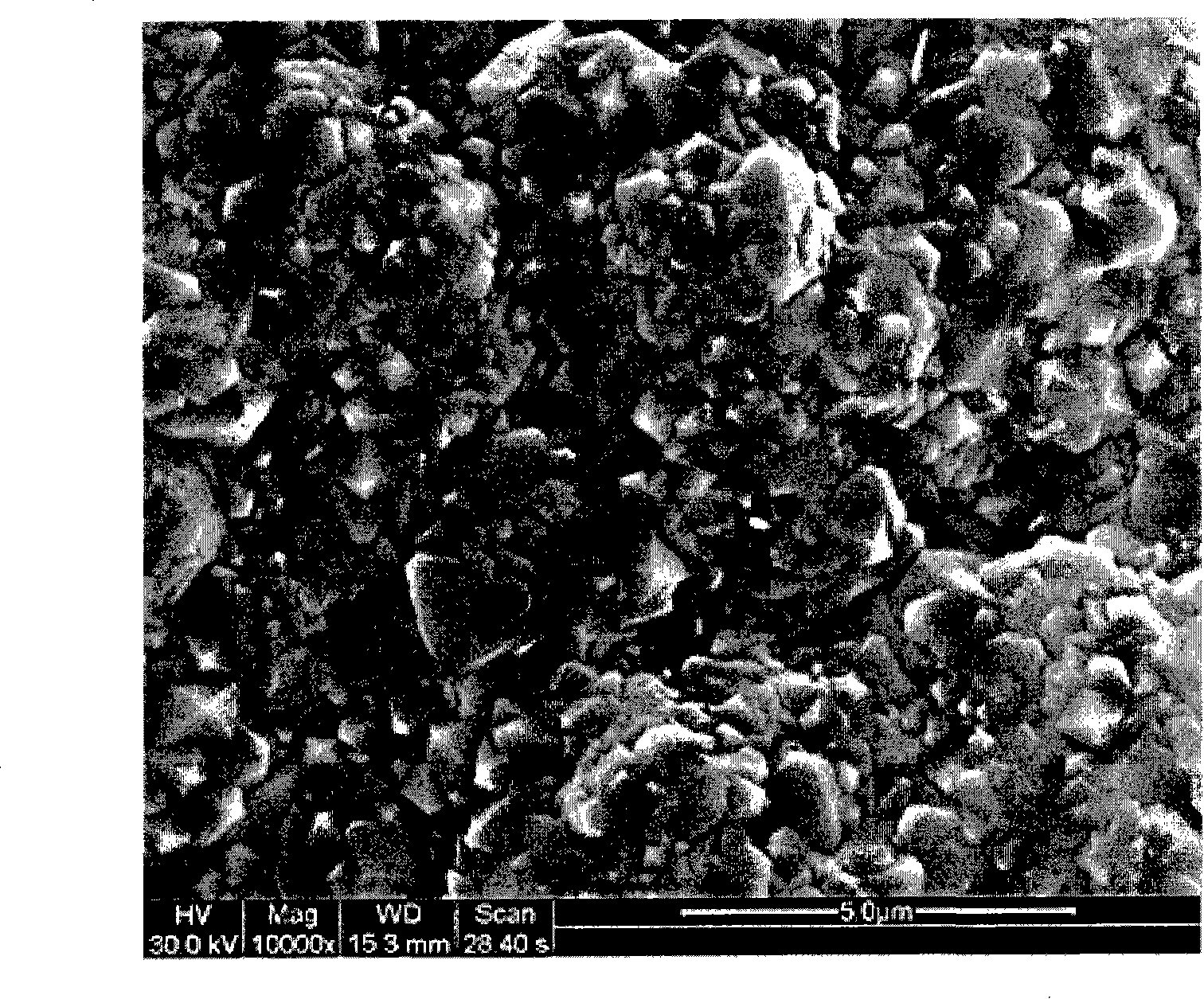

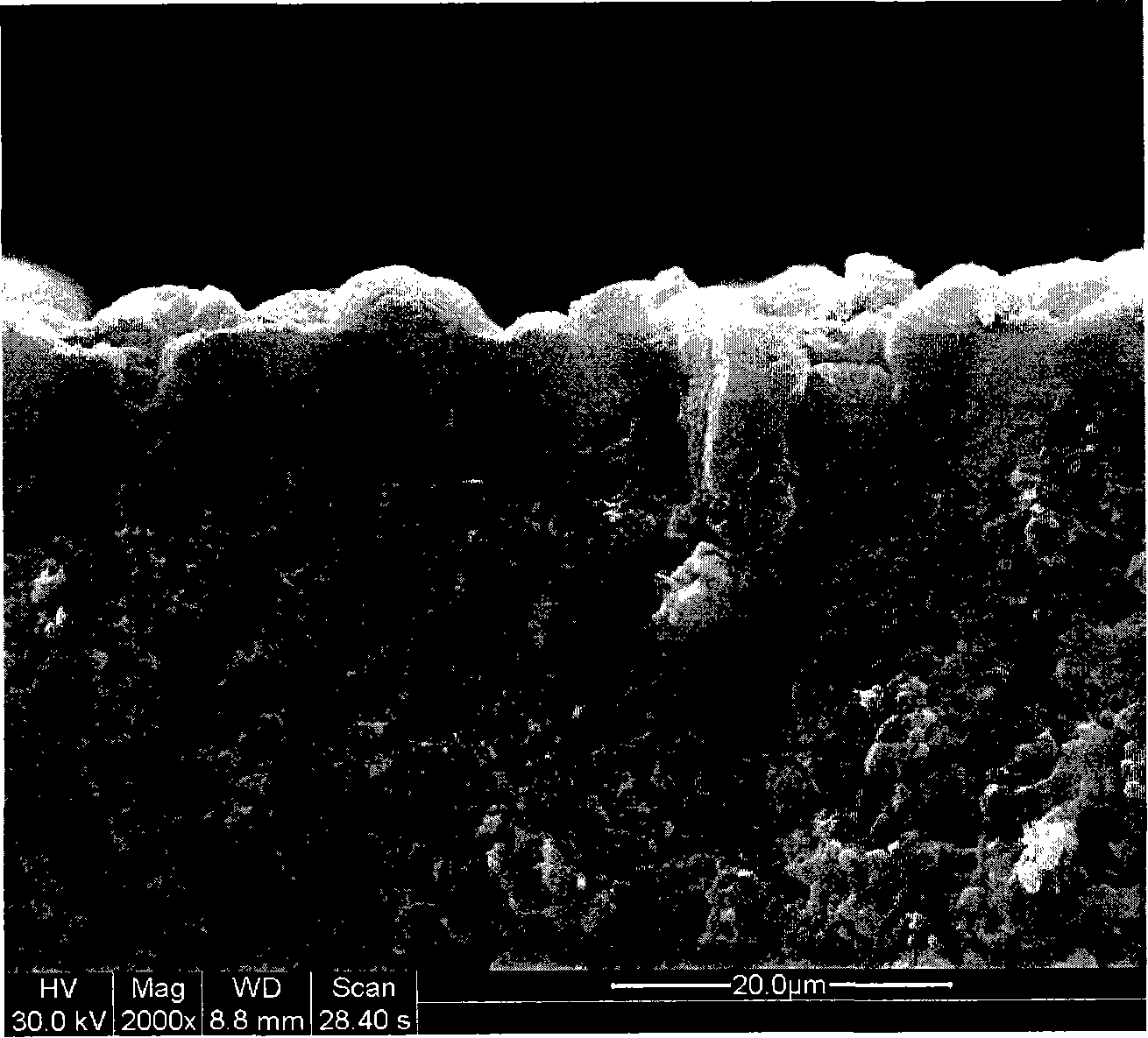

Method for preparing high-performance Y type molecular sieve film and application of the same in organic mixture separation

InactiveCN101318665AHigh purityShort synthesis timeFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteSeparation factorMolecular sieve

The invention provides a method for preparing a high-performance Y-type molecular sieve membrane and an application to the separation of organic mixture. The method is characterized in that a new high-temperature closed hydro-thermal synthesis reaction method is adopted, a layer of dense NaY-type molecular sieve membrane forms on the surfaces of three porous tubular support body. The synthetic time of preparation process is short, and the process of the membrane forming is simple. The membrane prepared by the method has fewer defects, the synthesized NaY-type molecular sieve membrane is used in the separation of organic mixtures by adopting a self-control permeating and vaporizing device, the process of the separation is simple and is easy to be operated and controlled, the separating property is good, the Y-type molecular sieve membrane has high permeation flux and high separation factor while the Y-type molecular sieve membrane is applied to methanol / methyl tert-butyl ether, ethanol / ethyl tertiary butyl ether and benzene / cyclohexane, the NaY-type molecular sieve membrane particularly synthesized by stainless steel support body has extremely high permeation flux.

Owner:JIANGXI NORMAL UNIV

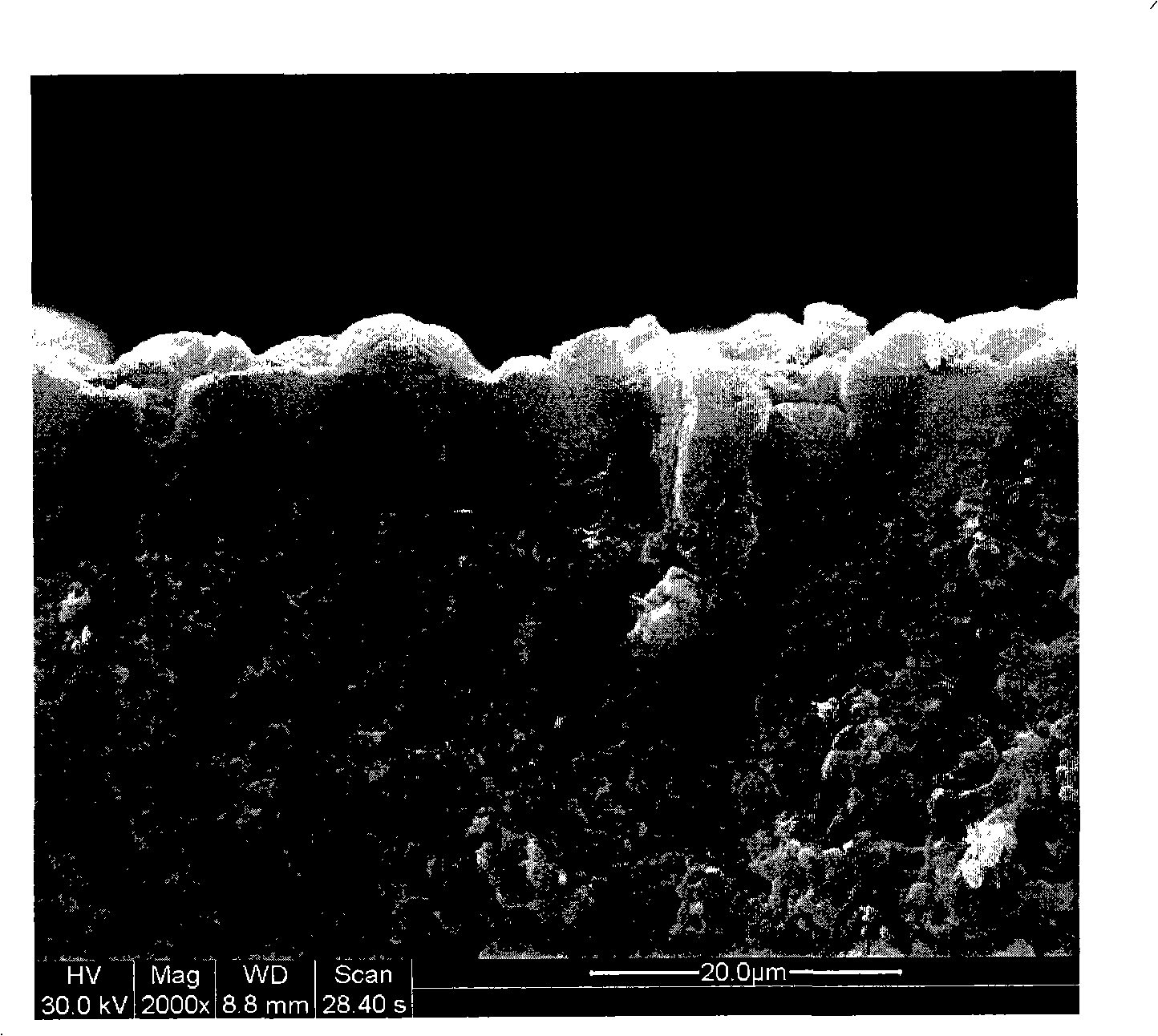

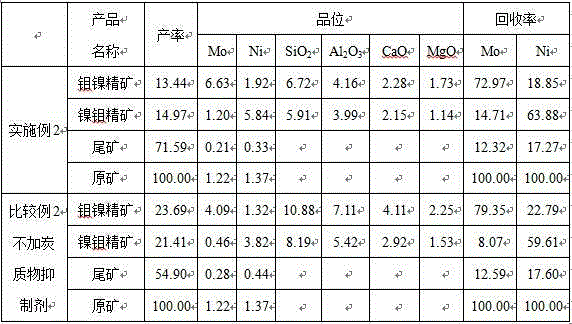

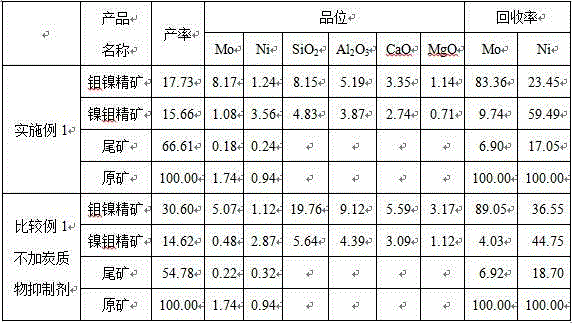

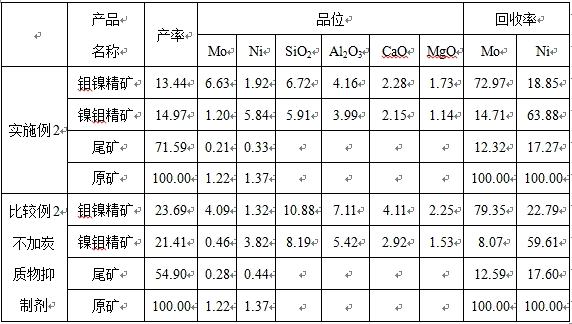

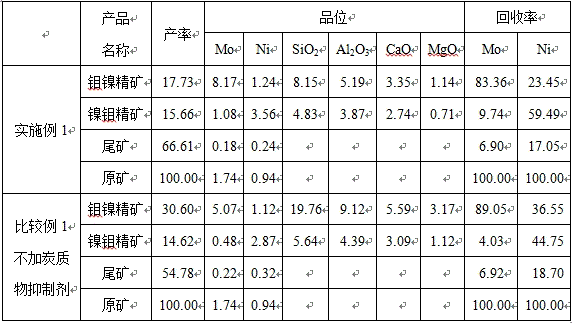

Carbon inhibitor and application thereof in molybdenum-nickel flotation from high-carbon molybdenum-nickel ores

The invention discloses carbon inhibitor and application thereof in molybdenum-nickel flotation from high-carbon molybdenum-nickel ores. The carbon inhibitor contains, by weight, 40-120 parts of acid orange, 20-60 parts of ethyl tert-butyl ether, and 60-180 parts of CMC (carboxymethyl cellulose). The invention further discloses a flotation method using the carbon inhibitor. The flotation method includes the steps of grinding, molybdenum flotation and nickel flotation; each of the molybdenum flotation and nickel flotation steps includes one to two times of roughing, two to four times of concentration and one to three times of scavenging; molybdenum concentrate and nickel concentrate are finally obtained. Compared with the prior art, the carbon inhibitor and the floatation method thereof have the advantages that separation efficiency is high, molybdenum-nickel ores and carbon can be effectively separated, grade of the molybdenum and nickel concentrates is increased, beneficiation cost is low, the process flow is simple and reliable, and usage and operation are easy.

Owner:纳雍县汇丰矿业有限公司 +1

Additive for gasoline and diesel oil and its prepn process

InactiveCN1931970AIncrease the itineraryAchieve environmental protectionLiquid carbonaceous fuelsBenzeneNaphtha

The present invention discloses one kind of additive for gasoline and diesel oil and its preparation process. The additive consists of naphtha 1-59 wt%, methanol 10-79 wt%, triethanolamine 1-40 wt%, isopropanol 1-39 wt%, tetrahydrofuran 1-39 wt%, and butanol 1-45 wt%, where, naphtha may be replaced with benzene and methyl acetate, triethanolamine with diethanolamine, and tetrahydrofuran with ethyl tertiary butyl ether. The preparation process of the additive includes the steps of mixing isopropanol and methanol, adding naphtha after stilling, and adding the other components to obtain the product. The additive for gasoline and diesel oil may be replace gasoline and diesel oil partially to reach environment protecting and energy saving effects.

Owner:刘连强

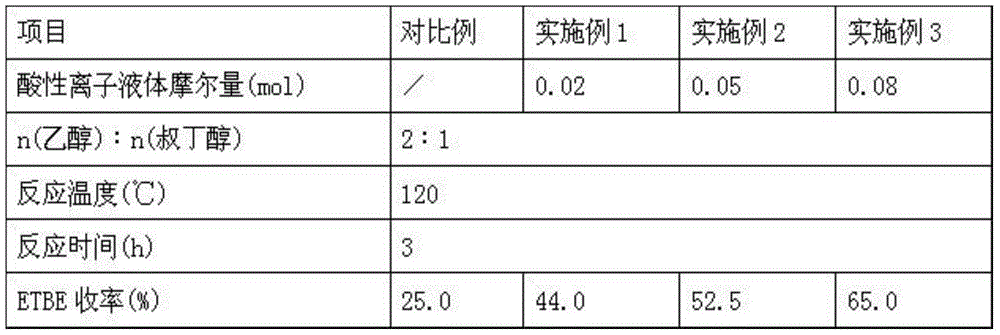

Preparation method of acidic polystyrene resin catalyst for synthesis of ethyl tert-butyl ether

InactiveCN105566550AOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation by compound dehydrationPolystyreneThermal stability

The invention discloses a preparation method of an acidic polystyrene resin catalyst for synthesis of ethyl tert-butyl ether. An electron withdrawing group -CH2Cl is introduced between an aromatic ring and an acidic functional group of polystyrene resin to prepare a series of acidic polystyrene resin catalyst so as to reach the purpose of improving the thermal stability of the polystyrene resin catalyst. The prepared catalysts can be used for synthesis of ethyl tert-butyl ether. The catalyst shows high catalytic activity, and the yield of ethyl tert-butyl ether is in the range of 44.0%-65.0%.

Owner:SINOPEC YANGZI PETROCHEM +1

Improved multi-functional fuel oil additive

InactiveCN104327893AImprove low temperature resistanceAnti-corrosionLiquid carbonaceous fuelsFuel additivesPhosphorous acidCarbamate

The invention relates to an improved multi-functional fuel oil additive. The improved multi-functional fuel oil additive is prepared from the following raw materials in parts by weight: 5-9 parts of lauroyl diethanolamide, 3-6 parts of carboxylic ester, 5-7 parts of polyether acetate, 4-8 parts of non-ionic surface active agent, 6-8 parts of petroleum solvent, 6-10 parts of glycerol monostearate, 3-9 parts of petroleum calcium sulfonate, 1-5 parts of ethyl tert butyl ether, 1-4 parts of combustion improver, 4-9 parts of boronized succinimide, 2-7 parts of cupric isooctoxylborate, 3-8 parts of polyisobutene carbamate, 5-8 parts of dibutyl phosphite and 1-3 parts of viscosity index improver. The improved multi-functional fuel oil additive can improve the low temperature resistance of fuel oil, has corrosion-resistant and lubricating functions and can protect the engine.

Owner:QINGDAO TOPLINK INFORMATION TECH

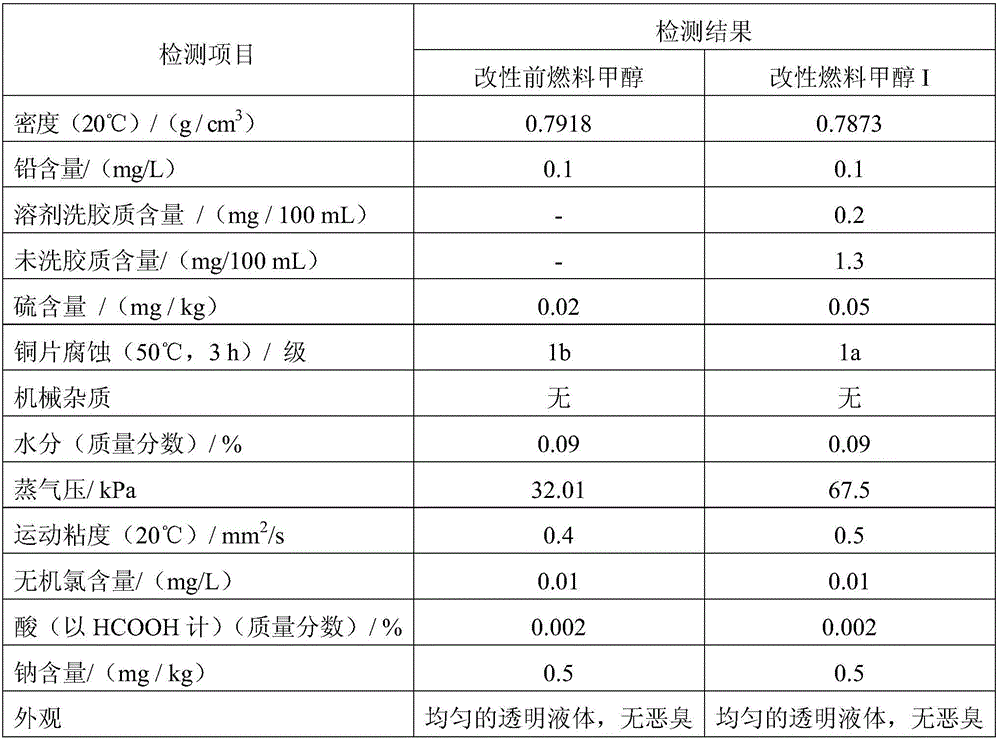

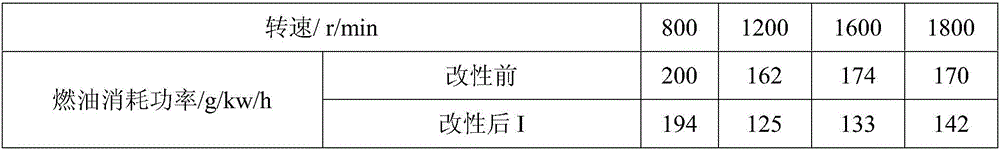

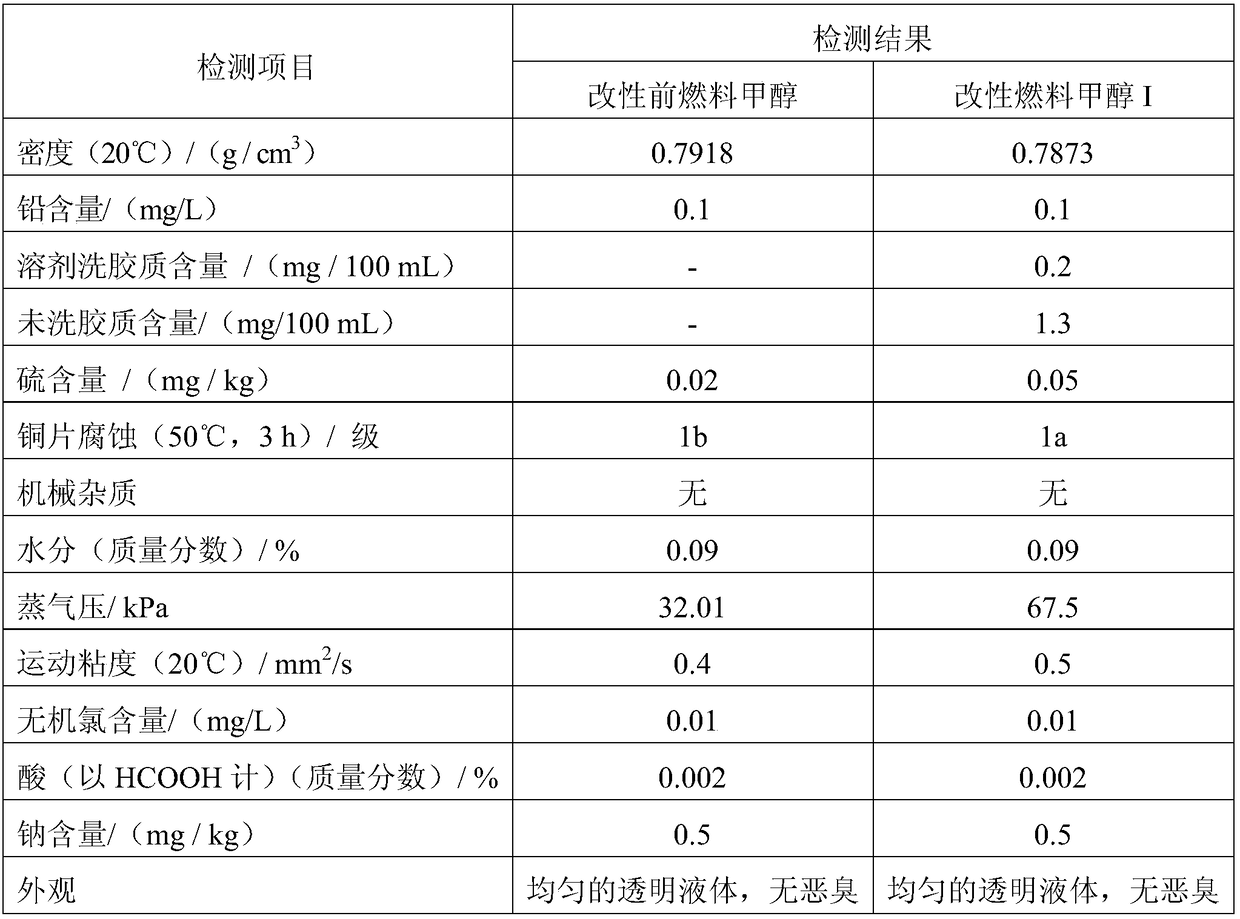

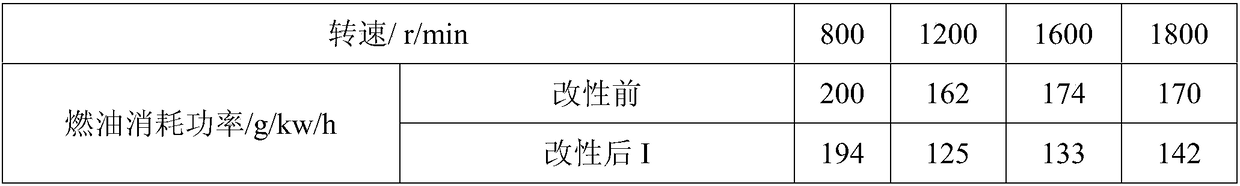

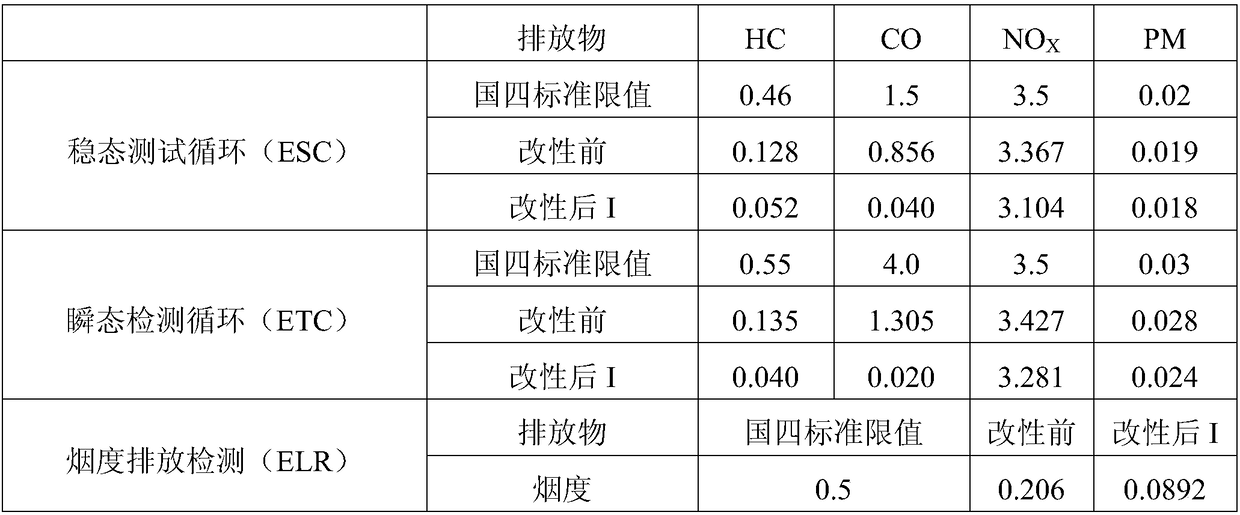

Modified vehicle fuel methanol suitable for methanol/diesel combined combustion system

InactiveCN106520221AImprove atomization effectImproved diffusion combustibilityLiquid carbonaceous fuelsOxygenMixed gas

The invention provides modified vehicle fuel methanol suitable for a methanol / diesel combined combustion system. The modified vehicle fuel methanol comprises the following components in percentage by mass: 94-96% of methanol and 4-6% of a compound modifier; the compound modifier comprises the following components in percentage by weight: 7-18% of a lubricant, 5-11% of a cosolvent, 0.3-0.8% of an anti-oxygen anti-corrosion agent and a compound atomization modifier in balancing amount; and the compound atomization modifier is prepared by mixing pentane, ETBE (Ethyl Tertiary Butyl Ether), methylal and acetone. The modified vehicle fuel methanol provided by the invention is improved in atomization property, diffusive combustibility and lubricity and restrained in metal corrosion; and after the modified vehicle fuel methanol is applied to the methanol / diesel combined combustion system, the problem that an engine body is corroded by fuel methanol is solved, the combustion efficiency of mixed gas in a cylinder is further improved, fuels are promoted to completely burn, the acceleration property of an engine and the fuel economy are improved, and the emission of harmful gas is greatly reduced.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

Method for preparing high-performance Y type molecular sieve film and application of the same in organic mixture separation

InactiveCN101318665BHigh purityShort synthesis timeSemi-permeable membranesFaujasite aluminosilicate zeoliteBenzeneMolecular sieve

The invention provides a method for preparing a high-performance Y-type molecular sieve membrane and an application to the separation of organic mixture. The method is characterized in that a new high-temperature closed hydro-thermal synthesis reaction method is adopted, a layer of dense NaY-type molecular sieve membrane forms on the surfaces of three porous tubular support body. The synthetic time of preparation process is short, and the process of the membrane forming is simple. The membrane prepared by the method has fewer defects, the synthesized NaY-type molecular sieve membrane is used in the separation of organic mixtures by adopting a self-control permeating and vaporizing device, the process of the separation is simple and is easy to be operated and controlled, the separating property is good, the Y-type molecular sieve membrane has high permeation flux and high separation factor while the Y-type molecular sieve membrane is applied to methanol / methyl tert-butyl ether, ethanol / ethyl tertiary butyl ether and benzene / cyclohexane, the NaY-type molecular sieve membrane particularly synthesized by stainless steel support body has extremely high permeation flux.

Owner:JIANGXI NORMAL UNIV

Low-carbon gasoline detergent

InactiveCN110804469ABurn fullyHigh calorific valueLiquid carbonaceous fuelsFuel additivesOctanolEthyl acetate

The invention relates to a low-carbon gasoline detergent. The low-carbon gasoline detergent is composed of the following raw material components in parts by weight: 5-28 parts of o,o'-bis(2-aminopropyl)polypropyleneglycol, 1-4 parts of isobutyramide, 2-5 parts of methylcyclopentadienyl manganese tricarbonyl, 1-4 parts of tert-butyl methyl ether, 3-6 parts of tert-butyl ethyl ether, 0.1-0.6 part ofhexamethylphosphoramide, 2-4 parts of butanol, 8-16 parts of octanol, 2-6 parts of ethyl acetate, 0.2-2 parts of a detergent, 0.1-0.5 part of an antioxidant, 0.1-0.8 part of isododecane, 15-30 partsof naphtha and 1-8 parts of a friction reducing agent. According to the technical scheme, the provided low-carbon gasoline detergent has the advantages that the gasoline detergent is environmentally friendly, economic and high in heat value, not only benefits sufficient combustion of gasoline, but also can reduce emission of harmful gas of carbon monoxide, sulfur-containing gas and the like in tail gas, and can reduce emission of particles in the tail gas, and the swelling property and air lock of modified methanol gasoline are well overcome.

Owner:张传祥

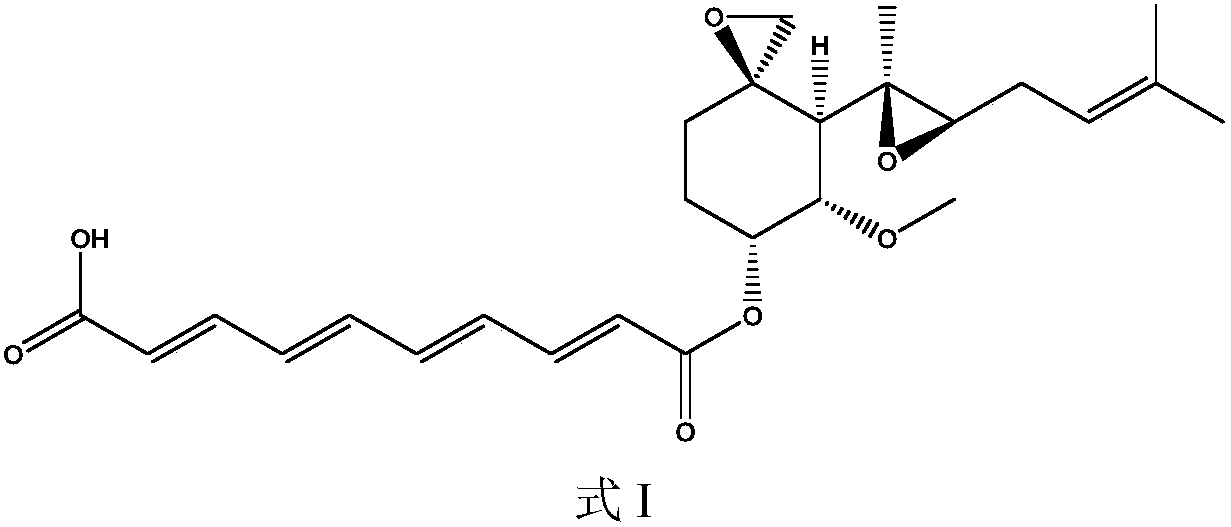

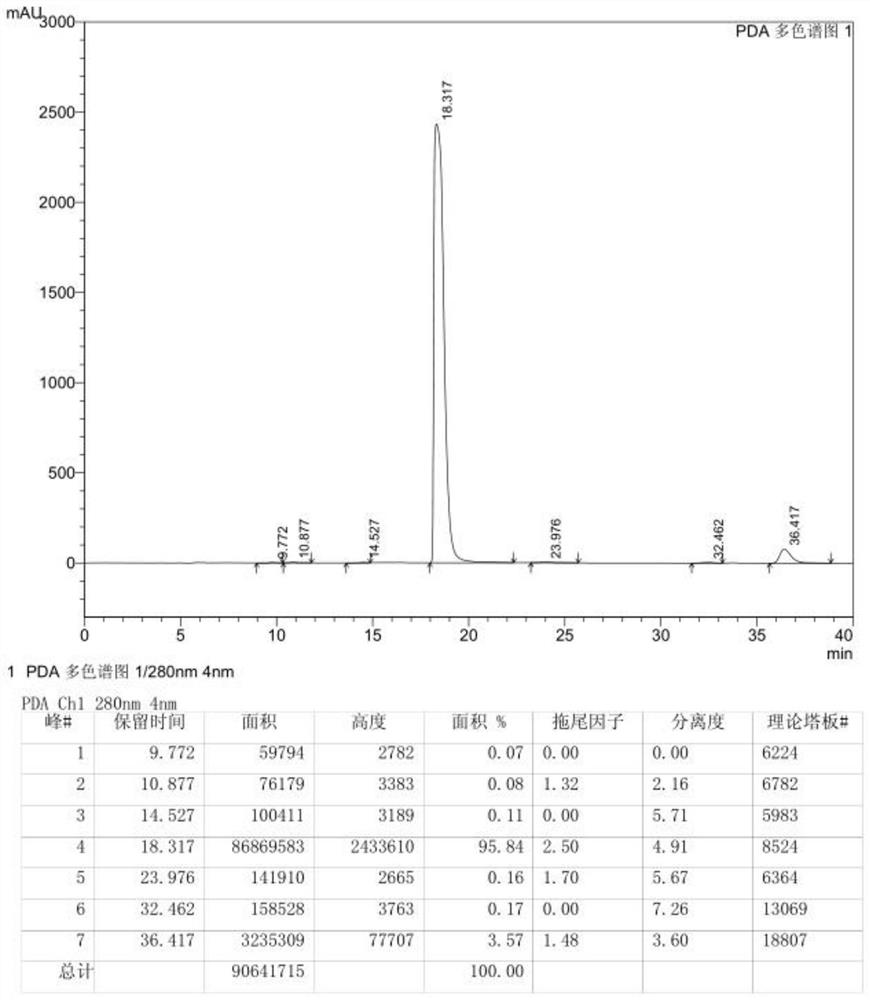

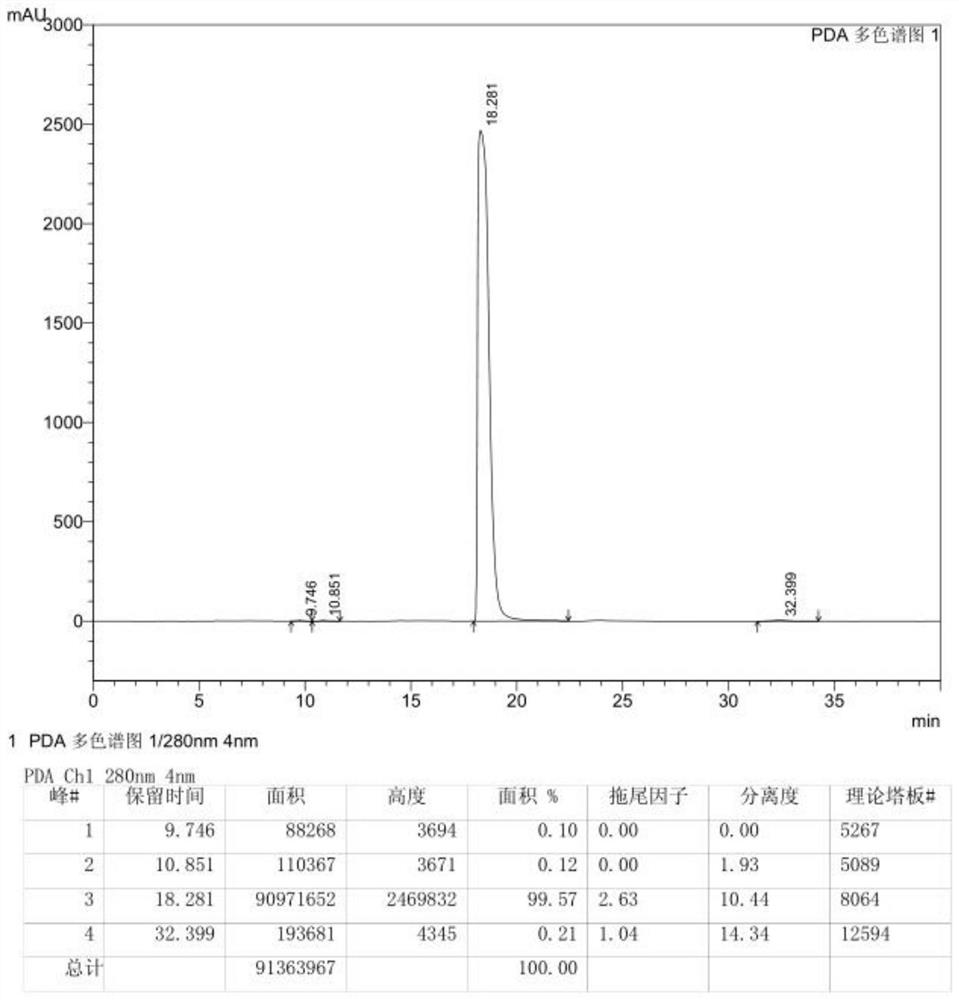

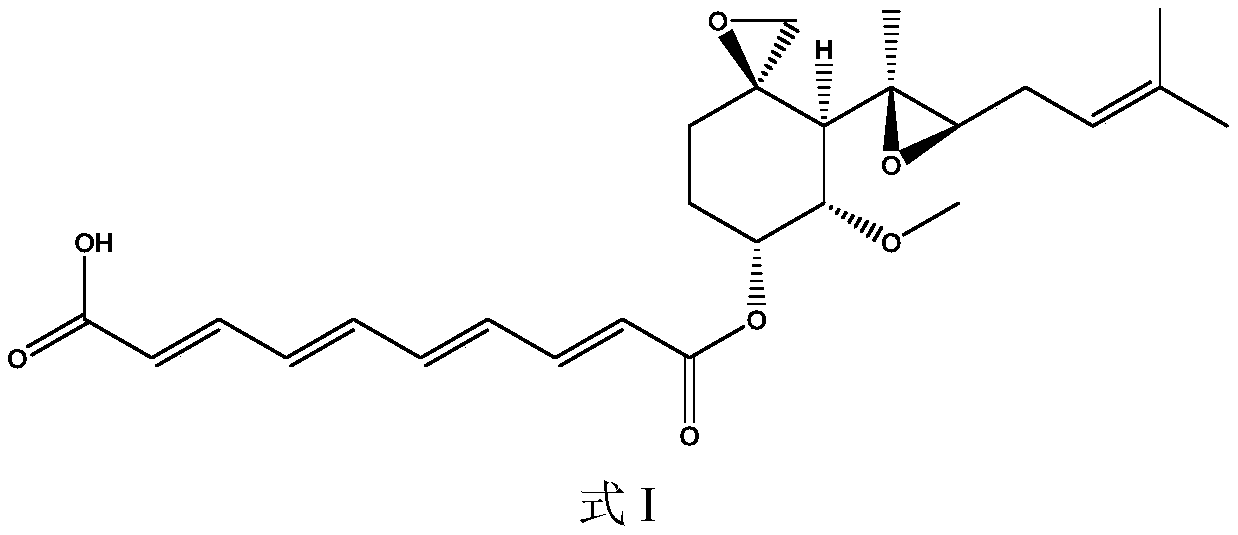

Fumagillin extraction and purification method

ActiveCN109053638AIncrease contentLarge-scale industrial productionOrganic chemistryPurification methodsFermentation

The invention discloses a fumagillin extraction and purification method which comprises steps of extracting a methyl tertiary butyl ether (MTBE) or ethyl tertiary butyl ether (ETBE) fermentation liquid, purifying precipitate or crystal of MTBE or ETBE, and the like. The method is simple to operate, high in yield, low in cost and possible in large-scale industrial production, and has great significances for industrial production of fumagillin and later development of fumagillin derivatives.

Owner:ZHEJIANG HISUN PHARMA CO LTD

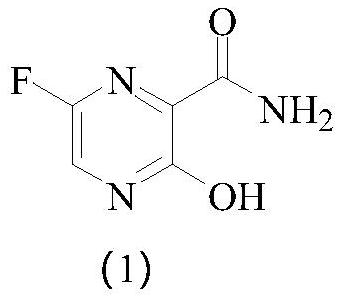

Crystallization and purification method of favipiravir key intermediate 3, 6-difluoropyrazine-2-carbonitrile

ActiveCN111793037AHigh purityHigh yieldOrganic chemistryAgainst vector-borne diseasesPyrazineEthyl group

The invention relates to a crystallization purification method, and relates to a crystallization purification method of a favipiravir key intermediate 3,6-difluoropyrazine-2-carbonitrile, and belongsto the field of medicinal chemistry. The method comprises the following steps: mixing a crude product of 3, 6-difluoropyrazine-2-carbonitrile with ethyl tert-butyl ether, stirring the materials, adding column chromatography silica gel; heating to 50-65 DEG C, performing stirring decolorization for a period of time, performing solid-liquid separation, cooling the resulting clarified solution, stirring and crystallizing for a period of time; then, performing solid-liquid separation, and obtaining the product 3, 6-difluoropyrazine-2-carbonitrile; wherein the mass ratio of the 3, 6-difluoropyrazine-2-carbonitrile crude product to the ethyl tert-butyl ether is 1: 3-1: 15, wherein the mass ratio of the 3, 6-difluoropyrazine-2-carbonitrile crude product to the column chromatography silica gel is1: 1. 0.5 to 1: 5, column chromatography silica gel is used as a decolorizing agent; ethyl tert-butyl ether is used as a crystallization solvent, crystallization conditions are controlled, tar in the3, 6-difluoropyrazine-2-carbonitrile can be effectively removed, the content of impurities 6-chloro-3-fluoropyrazine-2-carbonitrile is reduced, the crystallinity of the 3, 6-difluoropyrazine-2-carbonitrile is enhanced, the purity of the obtained product is high, operation is simple, and industrial production is facilitated.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

Batch extractive distillation separation method of ethyl tert-butyl ether/tert-butyl alcohol azeotropic mixture

InactiveCN105037112AEther separation/purificationOrganic compound preparationExtractive distillationSeparation technology

The invention discloses a batch extractive distillation separation method of an ethyl tert-butyl ether / tert-butyl alcohol azeotropic mixture and belongs to the separation technology of the ethyl tert-butyl ether / tert-butyl alcohol azeotropic mixture. In the method, a low-eutectic solvent, choline chloride, and ethyl glycol are employed as an extraction agent. The operation conditions of an extractive distillation column are represented as follows: mass ratio of the extraction agent to a top distillate is 0.2:1-10:1 and feeding temperature of the extraction agent is 20-60 DEG C. By means of control of different temperatures and reflux ratios at the top of the extractive distillation column, an ethyl tert-butyl ether product, an ethyl tert-butyl ether / extraction agent transition portion 1, a tert-butyl alcohol product, and an ethyl tert-butyl ether / extraction agent transition portion 2 are respectively withdrawn from the top of the extractive distillation column. When the composition of the extraction agent in a heating kettle achieves requirement, the extraction agent is pumped into a high-level liquid tank, and material is fed for performing the extractive distillation to next batch. The separation method is advantaged in that the extraction agent is employed for breaking the ethyl tert-butyl ether / tert-butyl alcohol azeotropic system, so that the ethyl tert-butyl ether and tert-butyl alcohol products can be separated out. The method is flexible in single column operation and is low in equipment cost.

Owner:UNIV OF JINAN

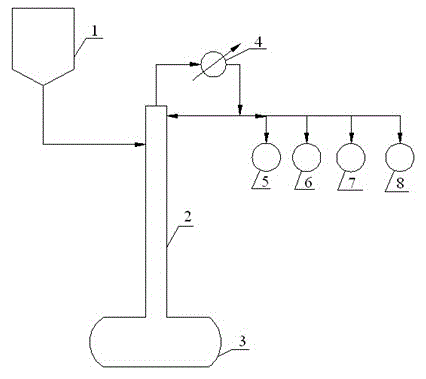

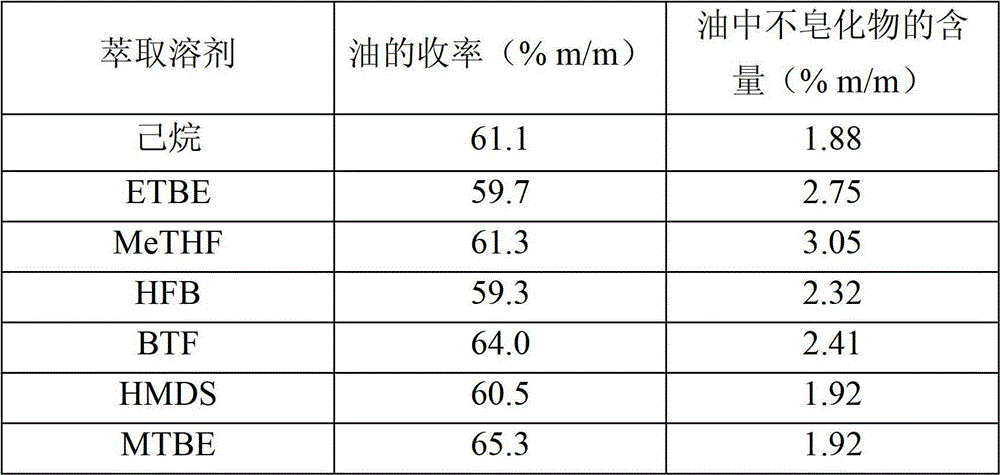

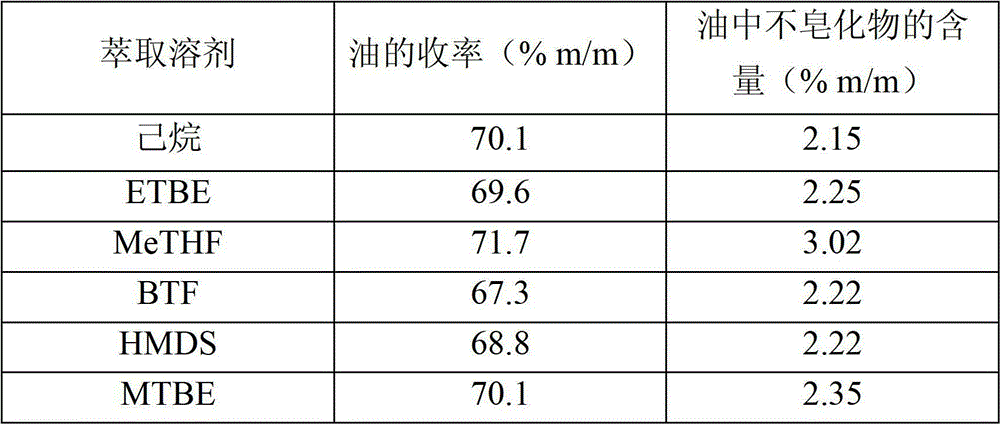

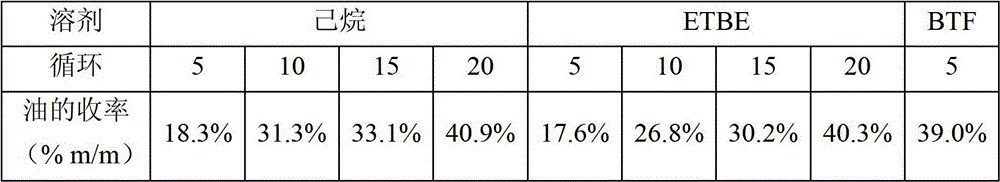

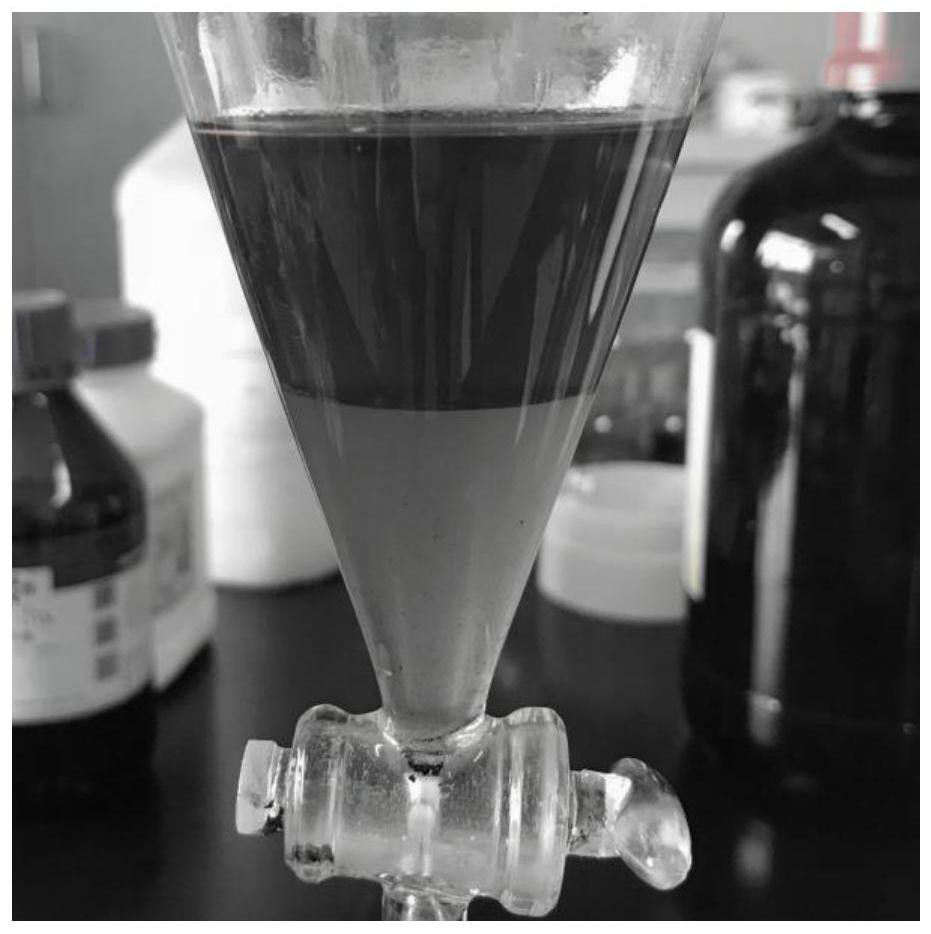

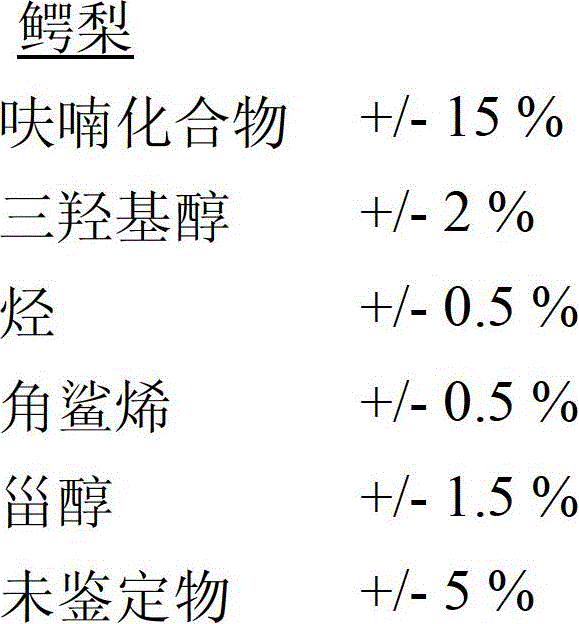

Solid/liquid extraction

InactiveCN102724887ACosmetic preparationsFatty acid esterification2-Methyl propane2-ethoxy-2-methylpropane

The invention relates to a method for the solid / liquid extraction of an oil or butter, particularly having a high unsaponifiable content, contained in at least one solid vegetable matter or a micro-organism. The method includes at least the following steps: solid / liquid extraction of at least one solid vegetable matter or a micro-organism using a first solvent system comprising a concentration of solvent selected from among fluorinated aromatic solvents, particularly trifluorotoluene (BTF) and hexafluorobenzene (BHF), tert-butyl ethers, particularly 2-ethoxy-2-methylpropane, also known as ethyl-tert-butyl-ether (ETBE), and 2-methoxy-2-methylpropane or methyl-tert-butylether (MTBE), solvents comprising at least one silicon atom, particularly hexamethyldisiloxane (HMDS) and tetramethylsilane (TMS), methyl-tetrahydrofuran (MeTHF), and mixtures thereof, representing at least 50 vol.-% in relation to the total volume of the solvent system; and, optionally, recovery of a fraction comprising the oil or butter, particularly unsaponifiable enriched. The invention also relates to an unsaponifiable fraction, oil or butter obtained using this method and to compositions containing said oil or fraction.

Owner:LAB EXPANSCIENCE

Alcohol gasoline and preparation method thereof

The invention discloses an alcohol gasoline and a preparation method thereof. The alcohol gasoline comprises, by weight, 15 to 55 parts of naphtha, 5 to 15 parts of mixed xylenes, 5 to 25 parts of toluene, 2 to 14 parts of methanol, 1 to 13 parts of isopropanol, 5 to 15 parts of C9 petroleum hydrocarbon, 1 to 15 parts of isopentane, 1 to 17 parts of methyl tert-butyl ether and 1 to 17 parts of ethyl tert-butyl ether. The alcohol gasoline has the advantages of good stability, low corrosion to an engine, good cost performance and low emission of pollutants from automobile exhaust. Meanwhile, the preparation method for the alcohol gasoline is simple and easily practicable and can be easily implemented.

Owner:李尧

A kind of alcohol ether ester methanol fuel

InactiveCN104449882BShortages are not affectedWide variety of sourcesLiquid carbonaceous fuelsIsobutanolPentyl ether

The invention discloses an alcohol-ether-ester methanol fuel. The alcohol-ether-ester methanol fuel is prepared from the following raw materials in percentage by weight: 60-80% of methanol, 10-20% of lower alcohol, 5-15% of ether and 5-12% of ester, wherein the lower alcohol is a mixture of ethanol, propanol, glycerol and isobutanol, the ether is a mixture of ethyl tertiary-butyl ether, methyl tert-pentyl ether, ethyl tert-pentyl ether and diisobutyl ether and the ester is a mixture of ethyl acetate, diethylene glycol fatty acid ester and dibutyl phthalate. By the alcohol-ether-ester methanol fuel, the problems of insufficient power, corrosiveness and swelling properties of the alcohol fuel are solved, the automobile engine need not to be modified, the gasoline can be directly replaced, the methanol fuel is clean and environmentally friendly, the exhaust emission is greatly reduced and the cost is low.

Owner:东奇能源技术有限公司

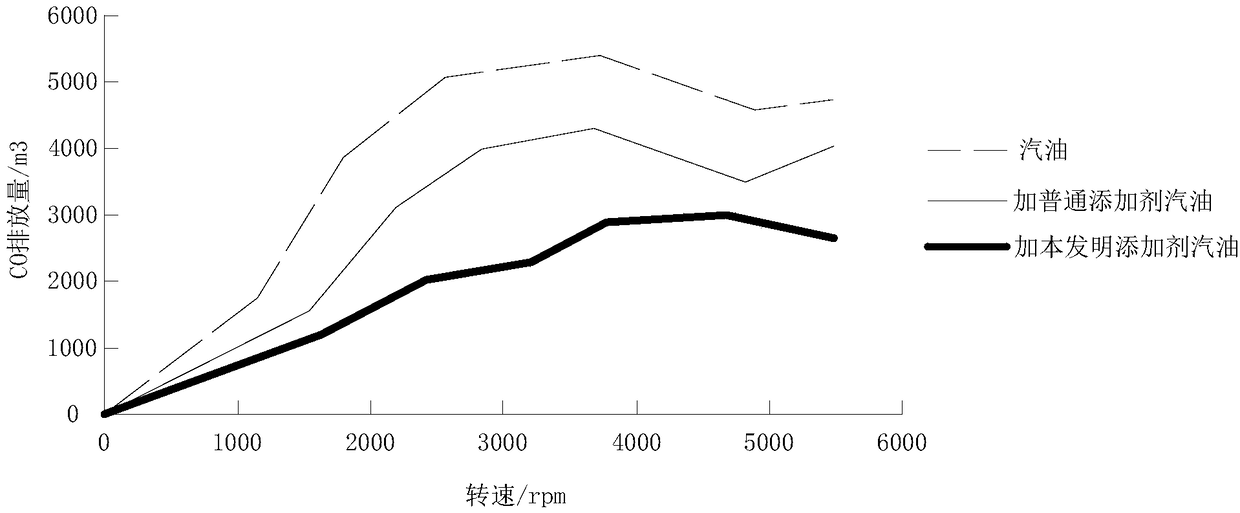

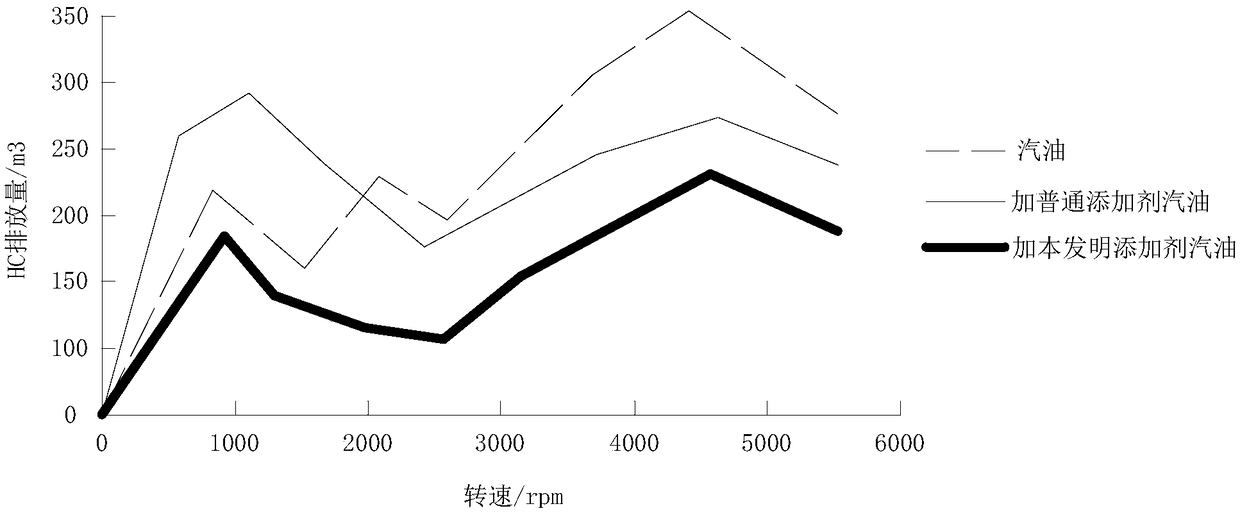

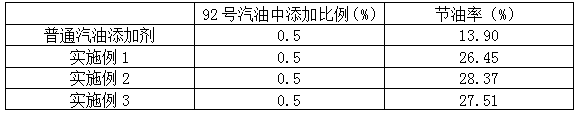

Energy-saving emission-reducing gasoline additive and preparation method and application thereof

InactiveCN108795519ASmall air resistanceBoost octaneLiquid carbonaceous fuelsFuel additivesFuel oilSorbitan

The invention discloses an energy-saving emission-reducing gasoline additive and a preparation method and application thereof, and belongs to the technical field of fuels. The energy-saving emission-reducing gasoline additive is prepared from denatured fuel ethanol, 2-ethyl hexanol, isopropyl alcohol, methylbenzene, ethyl tert butyl ether, paraffin hydrocarbon solution, a nonionic surfactant, bis-(3-triethoxysilylpropyl)-tetrasulfide, polyoxyethylene sorbitan fatty acid ester, ethyl nitrate and isooctyl nitrate; the energy-saving emission-reducing gasoline additive is applicable to fuel oils,has low addition quantity, high combustion efficiency, low gasoline consumption and good cleaning effect, emission of pollutants is decreased, and environmental pollution is relieved.

Owner:胡张艳

Alcohol-based fuel composite additive as well as preparation method and application thereof

The invention discloses an alcohol-based fuel composite additive as well as a preparation method and application thereof, and belongs to the technical field of fuel additives. The alcohol-based fuel composite additive comprises a base solvent, a cosolvent, a corrosion inhibitor and a water-dissolving agent, wherein the base solvent comprises isobutanol and camphor, the cosolvent comprises methyl tertiary butyl ether, ethyl tertiary butyl ether, methyl tertiary amyl ether, naphtha, xylene and petroleum ether; the corrosion inhibitor comprises benzotriazole, fatty alcohol-polyoxyethylene ether,alkylated diphenylamine, 2, 6-di-tert-butyl-4-methylphenol, N, N'-bis (salicylidene) -1, 3-diaminopropane and alkenyl succinate, wherein the water-dissolving agent comprises sorbitan trioleate, ethanol and methylal. The preparation method comprises the following steps: uniformly mixing and mixing the raw materials, the prepared alcohol-based fuel composite additive is good in stability, good in intersolubility and high in universality, has good environmental benefits, economic benefits and social benefits, and has a good market application prospect, and the preparation method is simple and issuitable for industrial popularization and application.

Owner:钱丰 +2

Environment-friendly biological fuel for boilers and preparation method of biological fuel

InactiveCN108949247AReduce manufacturing costIncrease profitLiquid carbonaceous fuelsFuel additivesPalm fruitEngineering

The invention provides environment-friendly biological fuel for boilers. The biological fuel comprises the following raw materials: 40-80 parts of a palm fruit extract, 2-8 parts of methanol, 2-8 parts of ethanol, 3-6 parts of oleic acid, 2-6 parts of polydimethylsiloxane, 1-3 parts of hexamethyl cyclotrisiloxane, 0.2-2.0 parts of dimethyl carbonate, 0.1-1.0 part of ethyl tertiary butyl ether, 1-3parts of a stabilizer, 0.2-0.6 part of a metal corrosion inhibitor and 1-4 parts of a phenolic antioxidant. The preparation method comprises the preparation of a palm fruit extract and the mixing ofthe materials. The biological fuel oil provided by the invention is low in production cost and high in fuel oil utilization rate, the anti-explosion performance and the oxidation resistance are good,the service life is long, and the environment friendliness is achieved. The extraction efficiency of the palm fruit extract is high, the preparation process of the biological fuel oil is simple, the raw materials are easy to mix, and the production cost is low, so that the biological fuel is suitable for large-scale production and is worthy of promotion.

Owner:天津庆源农机科技有限公司

A modified methanol fuel for vehicles used in a methanol/diesel co-combustion system

InactiveCN106520221BImprove atomization effectImproved diffusion combustibilityLiquid carbonaceous fuelsOxygenCompound modifier

The invention provides modified vehicle fuel methanol suitable for a methanol / diesel combined combustion system. The modified vehicle fuel methanol comprises the following components in percentage by mass: 94-96% of methanol and 4-6% of a compound modifier; the compound modifier comprises the following components in percentage by weight: 7-18% of a lubricant, 5-11% of a cosolvent, 0.3-0.8% of an anti-oxygen anti-corrosion agent and a compound atomization modifier in balancing amount; and the compound atomization modifier is prepared by mixing pentane, ETBE (Ethyl Tertiary Butyl Ether), methylal and acetone. The modified vehicle fuel methanol provided by the invention is improved in atomization property, diffusive combustibility and lubricity and restrained in metal corrosion; and after the modified vehicle fuel methanol is applied to the methanol / diesel combined combustion system, the problem that an engine body is corroded by fuel methanol is solved, the combustion efficiency of mixed gas in a cylinder is further improved, fuels are promoted to completely burn, the acceleration property of an engine and the fuel economy are improved, and the emission of harmful gas is greatly reduced.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

Cleaning type diesel fuel additive

InactiveCN105038875AIncrease motivationImprove the lubrication effectLiquid carbonaceous fuelsBenzoic acidPhosphorous acid

The invention discloses a cleaning type diesel fuel additive which is prepared from the following raw materials in part by weight: 6 to 12 parts of lauroyl diethanolamide, 7 to 9 parts of ethyl tert butyl ether, 2 to 4 parts of dibutyl phosphite, 5 to 10 parts of n-octanol, 7 to 11 parts of No.200 solvent oil, 8 to 10 parts of hydrogenated carbonyl phenol, 1 to 3 parts of methyl tert-butyl ether, 7 to 10 parts of petroleum ether, 2 to 6 parts of m-toluic acid, 9 to 13 parts of cyclohexyloxy copper borate, 8 to 11 parts of epoxy resin anti-yellowing agent, 3 to 5 parts of coconut diethanolamide, 9 to 12 parts of sorbitan monooleate, 10 to 15 parts of butyl oleate, 2 to 5 parts of dibutyl phosphite and 1.2 to 4 parts of benzotriazole. The cleaning type diesel fuel additive disclosed by the invention has the beneficial effects that the deposited carbon of a fuel system can be cleaned, the power of an engine is improved, and a good lubricating effect is realized.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

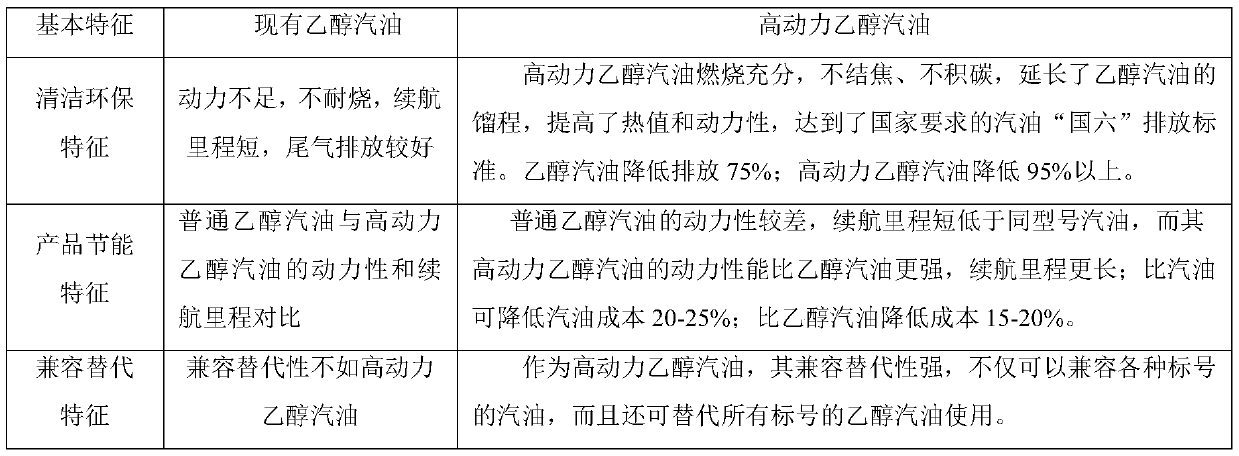

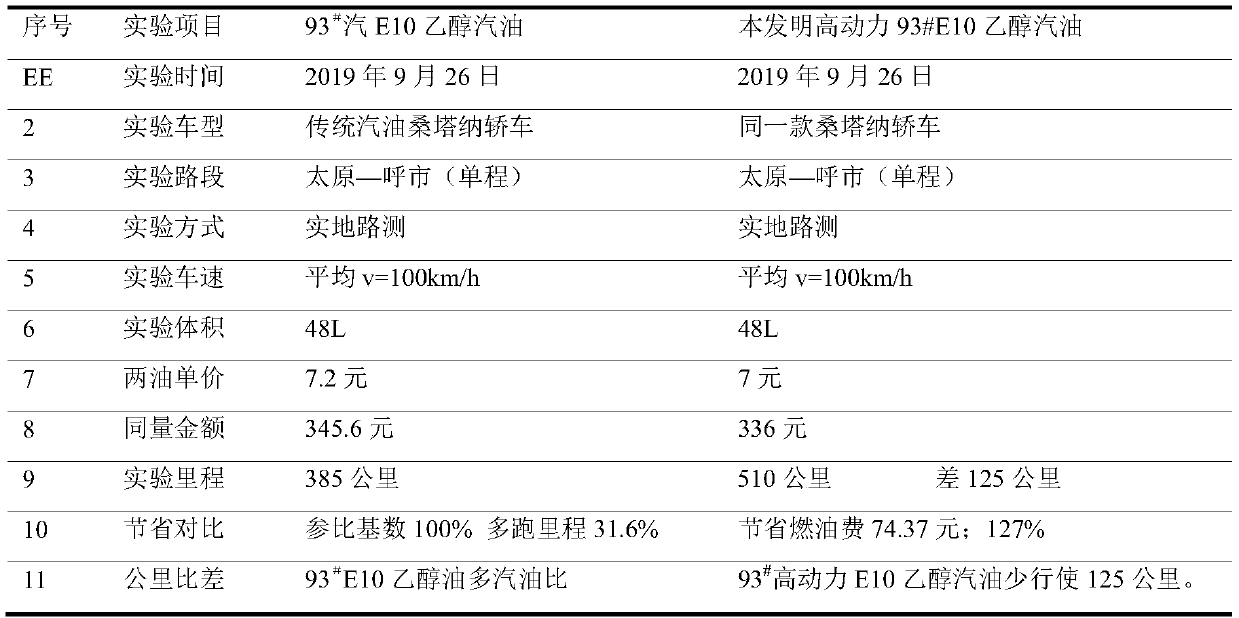

High-power range-extending component and ethanol gasoline prepared from high-power extended-range component

PendingCN111484882AIncreased after distillation rangeEfficient Pollution BurningLiquid carbonaceous fuelsNaphthaGasoline

The invention relates to the field of clean energy, in particular to a high-power range-extending component and ethanol gasoline prepared from the high-power range-extending component. The ethanol gasoline comprises the high-power range-extending component, sec-butyl ether, MTBE, ethyl tert-butyl ether, alkylated oil, naphtha, modified methanol, aromatic hydrocarbon and ethanol. According to the high-power range -extending component disclosed by the invention, the molecular structure in the high-power ethanol gasoline is changed, the after-distillation range of the ethanol gasoline is increased, the heat value and power of the high-power ethanol gasoline are improved, and meanwhile, the endurance mileage of the high-power ethanol gasoline is prolonged. The invention relates to the high-power ethanol gasoline. The high-power range-extending component for improving the power property of the ethanol gasoline and a new process for supplementing the after-distillation range of the ethanol gasoline and improving the combustion heat value are innovatively adopted to produce the high-power ethanol gasoline with physicochemical changed molecular structure, so that the high-power ethanol gasoline is optimized in quality molecular structure, more sufficient in combustion, better in dynamic property, more fuel-saving and long in endurance mileage.

Owner:孟首妃 +2

Method for synthesizing methyl methoxyacetate through carbonylation of formaldehyde

PendingCN114436845ANot corrosiveHigh yieldOrganic compound preparationCarboxylic acid esters preparationPtru catalystMethyl methoxyacetate

The invention relates to a method for synthesizing methyl methoxyacetate through carbonylation of formaldehyde, which adopts a carbonyl rhodium catalyst and comprises the following steps: (1) uniformly mixing the carbonyl rhodium catalyst with a solvent methyl tert-butyl ether and / or ethyl tert-butyl ether to obtain a mixture; (2) fully contacting a formaldehyde monomer source substance, CO, organic carboxylic acid and the mixture obtained in the step (1) for carbonylation reaction; after the reaction is finished, separating the solvent and the catalyst to obtain a carbonylation product; and (3) adding methanol into the carbonylation product for esterification reaction to generate methyl methoxyacetate. The method has the characteristics that the catalyst is non-corrosive to reaction equipment, the direct separation of the product and the catalyst and the direct recycling of the catalyst and the solvent are realized, and the energy consumption of the separation process and the production cost are effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Liquid/Liquid Extraction

The present invention relates to a process for the extraction of the unsaponifiable fraction contained in vegetable oils, oils or vegetable butters derived from microorganisms or in by-products from the vegetable oil refining industry (eg deodorization emissions). Said process comprises at least: A) a process comprising converting the aforementioned oils, butter or by-products from the vegetable oil refining industry or oils originating from microorganisms into a water-alcoholic solution by means of, inter alia, selected from the steps of saponification and esterification step; B) comprising the step of extracting said hydro-alcoholic solution by means of liquid / liquid extraction, wherein the fat fraction is separated from the unsaponifiable fraction; and C) comprising the optional step of purifying said unsaponifiable fraction, Said purification is selected from steps of crystallization and liquid / liquid extraction. According to the present invention, at least one of the liquid / liquid extraction step in step B, the crystallization step in step C and the liquid / liquid extraction step in step C is performed using a first solvent system comprising a concentration of Expressed as at least 50% by volume of solvent relative to the total volume of the solvent system, the solvent is selected from: fluorinated aromatic solvents (especially trifluorotoluene (BTF) and hexafluorobenzene (BHF)); tert-butyl ethers (especially 2‑ethoxy‑2‑methylpropane, also known as ethyl tert-butyl ether (ETBE)); solvents containing at least one silicon atom (especially hexamethyldisiloxane (HMDS ) and tetramethylsilane (TMS)); methyltetrahydrofuran (MeTHF) and mixtures thereof. The invention also relates to the fractions obtained using this method and to compositions containing said fractions.

Owner:LAB EXPANSCIENCE

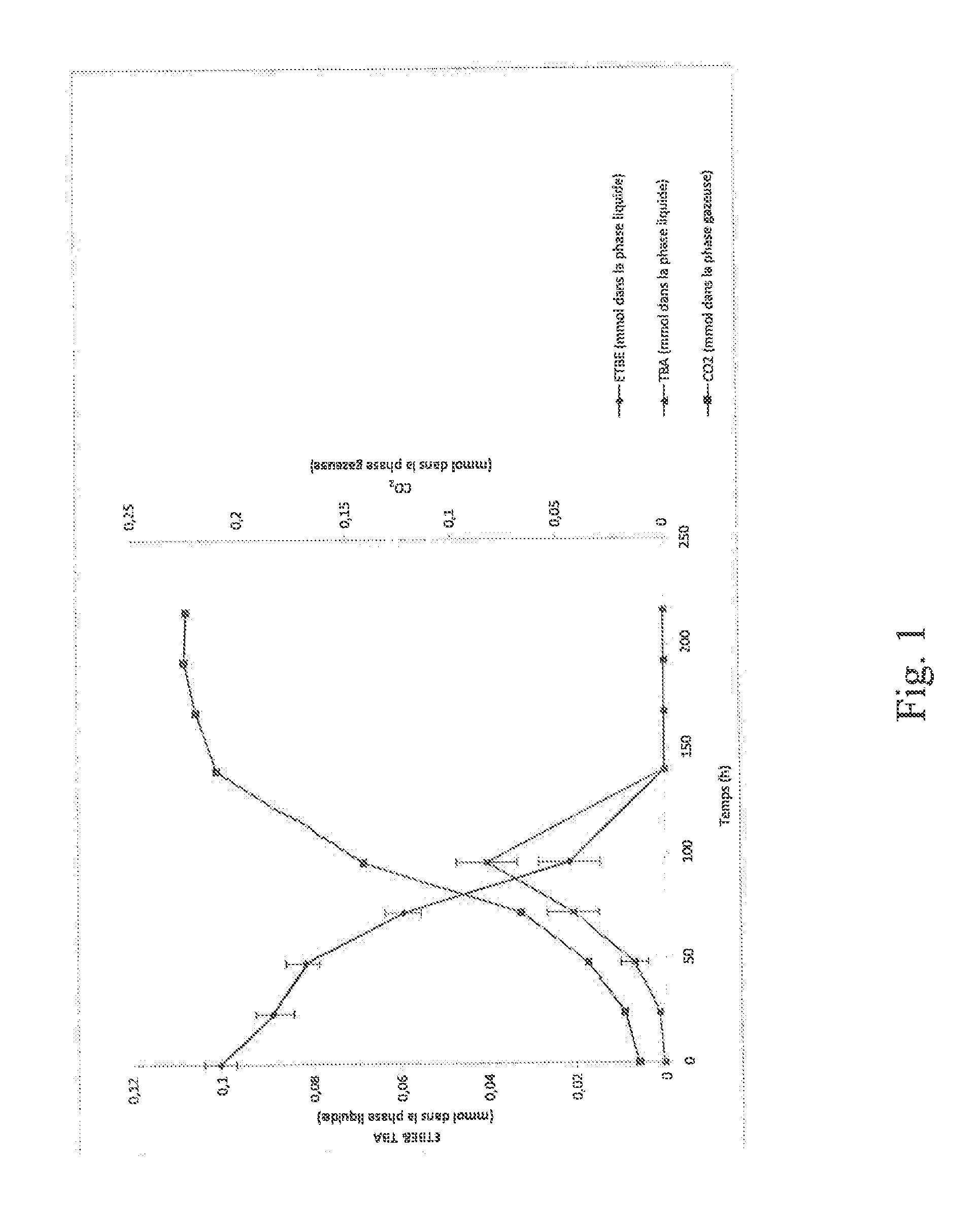

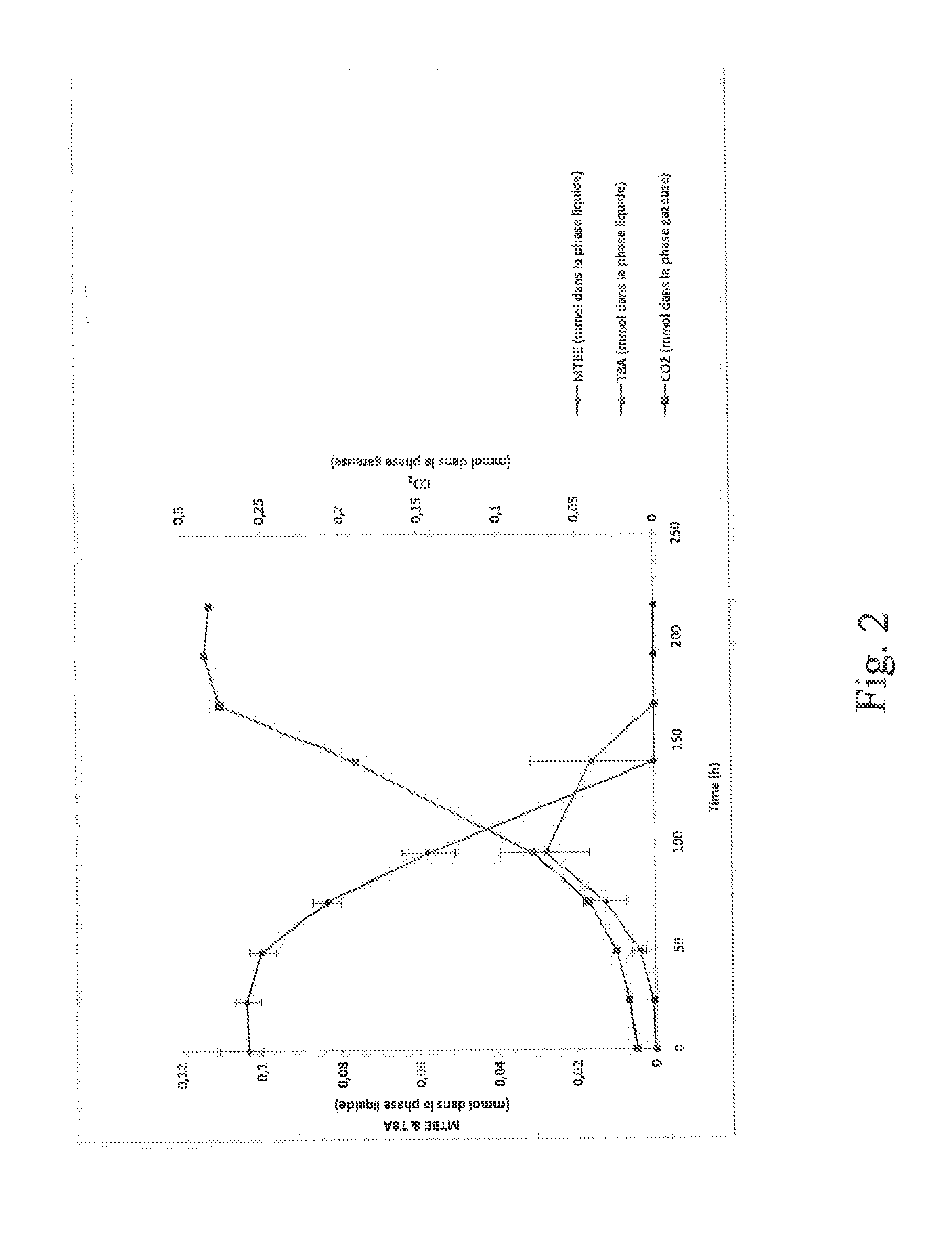

Bacteria of the genus pseudonocardia that are capable of degrading methyl tert-butyl ether (MTBE) or ethyl tert-butyl ether (ETBE) into a solution in effluent

This invention relates to bacteria of the genus Pseudonocardia, and in particular the strain deposited on Jul. 12, 2012 at the Pasteur Institute (CNCM, 25 rue du Docteur Roux, F-75724 PARIS Cedex 15, France) under No. CNCM 1-4656, capable of degrading MTBE and / or ETBE.The invention also relates to a process for treatment of an effluent comprising MTBE and / or ETBE and optionally TBA that uses such bacteria.

Owner:INST FR DU PETROLE

Ethanol-water separation method

InactiveCN109574804AEfficient mass separationEasy to dehydrateOrganic compound preparationHydroxy compound preparationGasolineEthyl tert-butyl ether

The invention provides an ethanol-water separation method which includes the steps: (1) performing azeotropy on hydrous ethanol raw materials and ethyl tert butyl ether at the temperature of 70-81 DEGC to obtain ethanol concentrate; (2) performing azeotropy on the ethanol concentrate and the ethyl tert butyl ether at the temperature of 63-68 DEG C and separating the ethanol concentrate and the ethyl tert butyl ether to obtain ethanol and H2O-ETBE azeotrope. According to the method, dilute ethanol is preliminarily concentrated, azeotropic dehydration is performed by the aid of the ethyl tert butyl ether to obtain the ethanol with the water content of hundreds of ppm, and the ethanol is used for blending ethanol gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

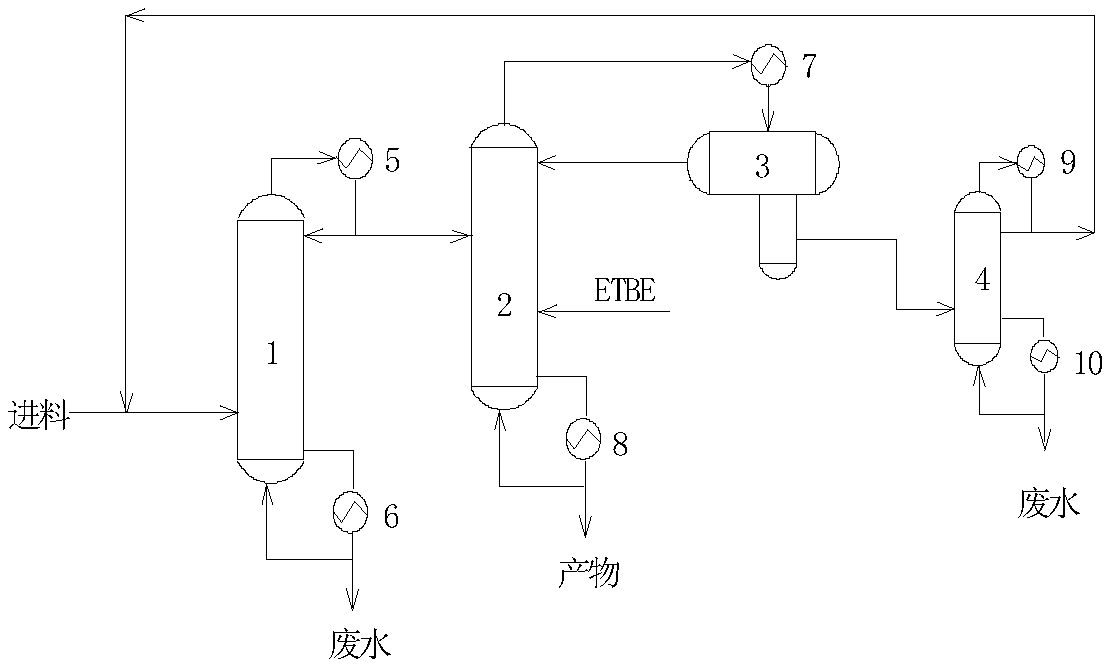

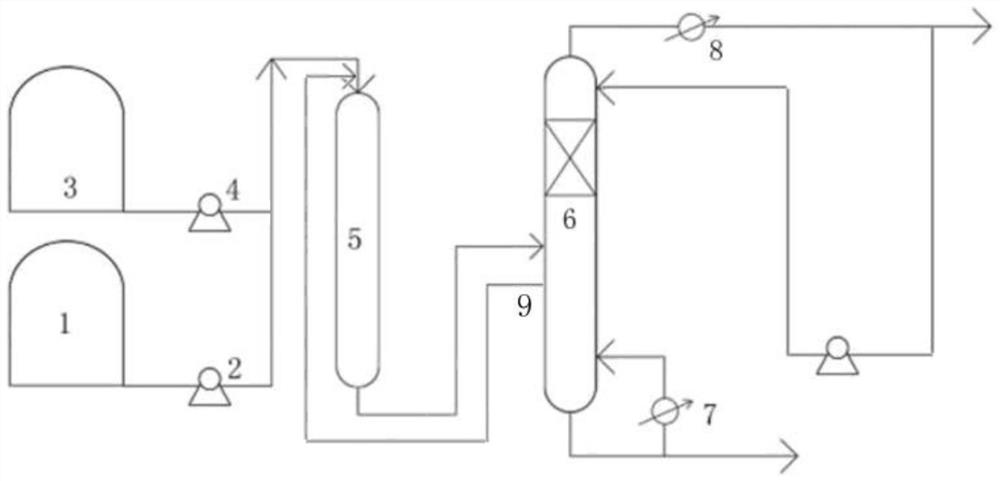

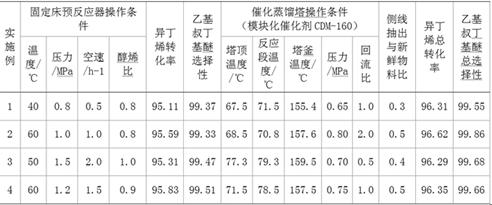

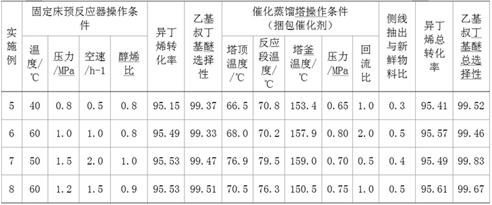

Preparation technology of ethyl tert-butyl ether etherification

ActiveCN108218675BDecrease the molar ratio of alcohol to eneneReduce consumption and energy consumptionEther separation/purificationOrganic-compounds/hydrides/coordination-complexes catalystsFluid phaseAlcohol ethyl

Owner:丹东明珠特种树脂有限公司

A carbon inhibitor and its application in the flotation of molybdenum and nickel from high carbon molybdenum-nickel ore

The invention discloses a carbonaceous substance inhibitor and its application in the flotation of molybdenum-nickel ore with high carbon molybdenum-nickel ore. The inhibitor contains the following components in parts by weight: 40-120 parts of acid orange, 20-60 parts Parts of ethyl tert-butyl ether and 60 to 180 parts of CMC. The invention also discloses a flotation method using the inhibitor, the flotation method includes three steps of grinding, molybdenum flotation and nickel flotation, each of the molybdenum flotation and nickel flotation undergoes 1 to 2 roughing , 2 to 4 selections and 1 to 3 sweeps. Finally, molybdenum concentrate and nickel concentrate are obtained. Compared with the prior art, the new inhibitor and its flotation method of the present invention have high separation efficiency, can effectively realize the separation of molybdenum-nickel minerals and carbonaceous substances, improve the grade of molybdenum and nickel concentrates, and have low ore dressing cost, The technological process is simple and reliable, and the operation is easy.

Owner:纳雍县汇丰矿业有限公司 +1

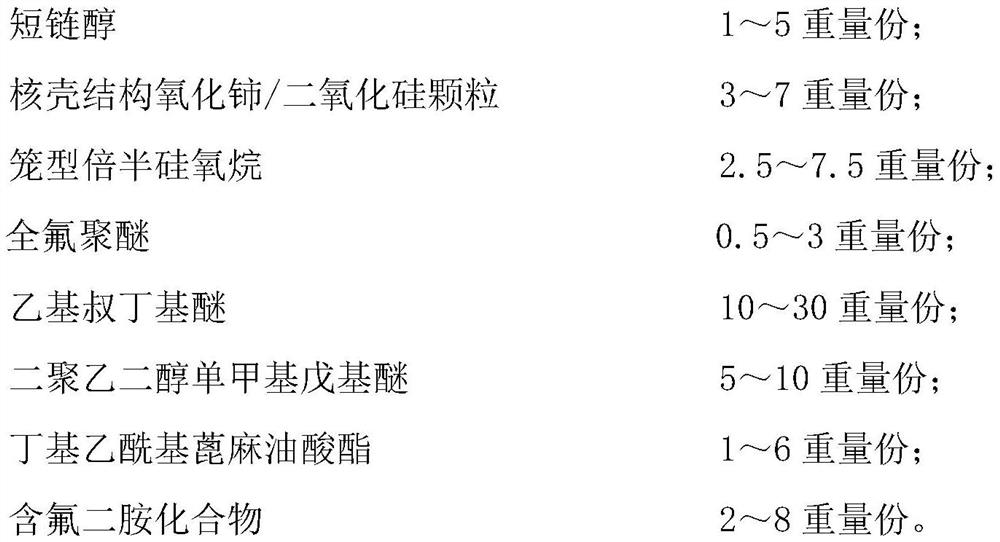

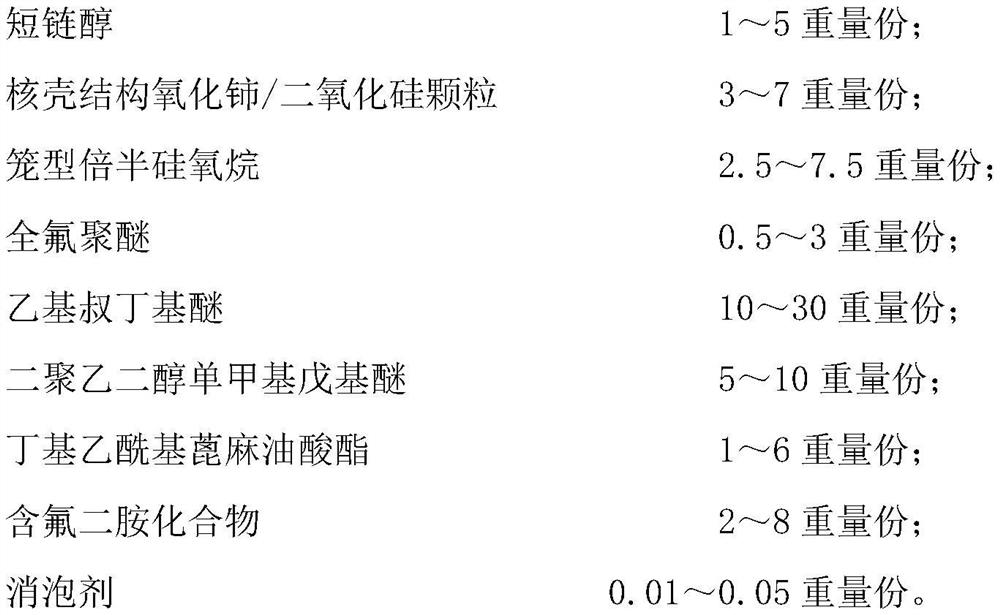

A kind of environment-friendly gasoline additive and preparation method thereof

ActiveCN110373235BExtended service lifeOptimize geometryLiquid carbonaceous fuelsPolythylene glycolEthyl group

Owner:交城县万里通加油站

Improved heavy oil additive

InactiveCN104449912AEmission reductionIncrease burn rateLiquid carbonaceous fuelsOil additiveEthyl group

The invention discloses an improved heavy oil additive which is prepared from the following raw materials in parts by weight: 1-3 parts of threonine, 2-5 parts of hydrogen peroxide, 1-4 parts of serine, 6-8 parts of fatty acid monoester, 3-9 parts of a combustion improver, 5-11 parts of sodium dodecyl benzene sulfonate, 5-7 parts of sodium sulfonate, 3-7 parts of dibasic lead stearate, 1-6 parts of dibasic phthalic acid lead, 3-5 parts of dimethyl silicon oil, 4-9 parts of pyrimethanil, 5-8 parts of polypropylene glycol, 3-6 parts of n-amyl alcohol and 2-6 parts of ethyl tert butyl ether. The improved heavy oil additive has the beneficial effects that heavy oil can be atomized, the combustion rate is increased, the discharge of pollutants is reduced, the energy is saved, and the environment is also protected.

Owner:QINGDAO TOPLINK INFORMATION TECH

A kind of extraction and purification method of fumagillin

ActiveCN109053638BIncrease contentLarge-scale industrial productionOrganic chemistryBiotechnologyMethyl t-butyl ether

Provided is a fumagillin extraction and purification method, which comprises the steps of extraction with a methyl t-butyl ether (MTBE) or ethyl t-butyl ether (ETBE) fermentation liquid, MTBE or ETBE precipitation, crystallization and purification, etc. The method is simple to operate, has a high yield, a low cost, can be industrialized on a large scale, and has great a significance for the industrialized production of fumagillin and the later development of a fumagillin derivative.

Owner:ZHEJIANG HISUN PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com