Alcohol-based fuel composite additive as well as preparation method and application thereof

A composite additive and alcohol-based fuel technology, which is applied in the field of fuel additives, can solve the problems of alcohol-based fuels, such as corrosive swelling, stability, insufficient fuel combustion, and decreased vehicle power performance, and achieve good market application prospects and extended use Life, emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

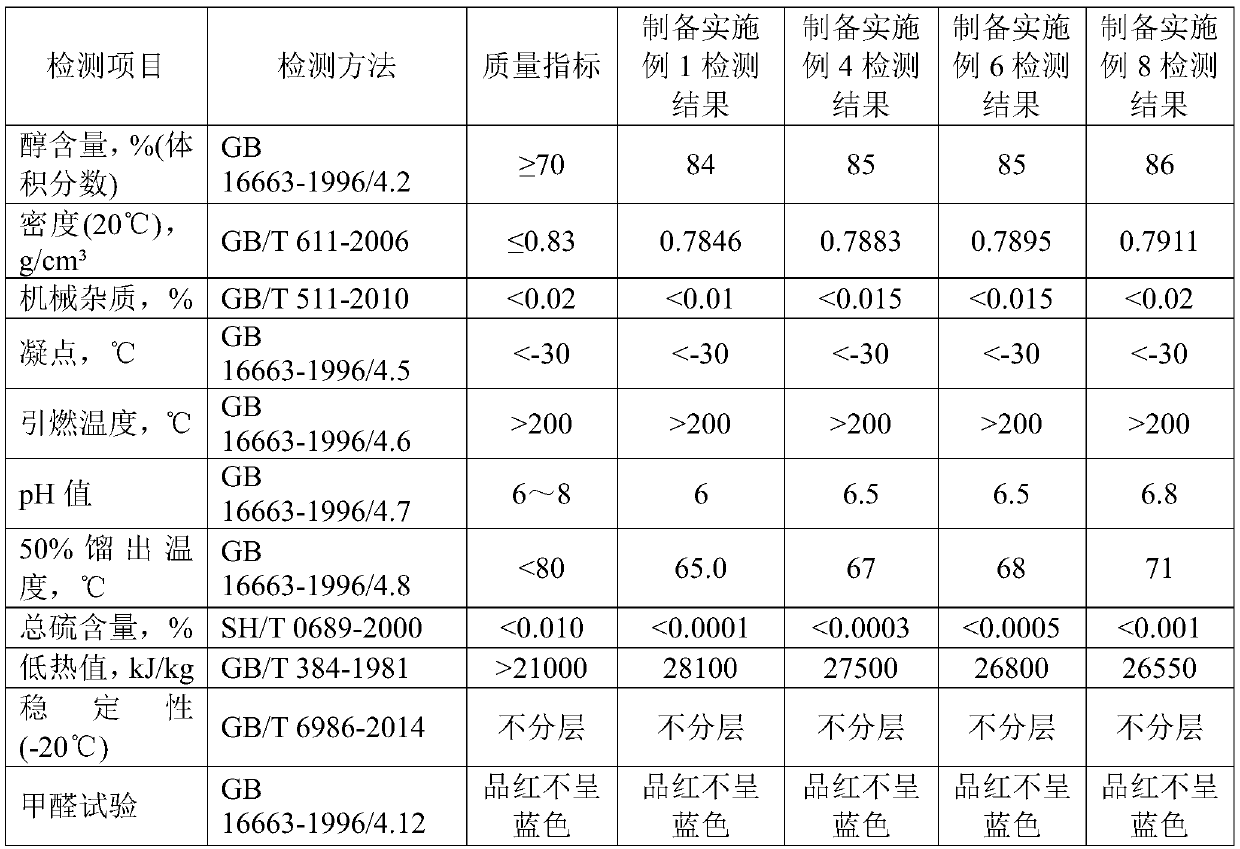

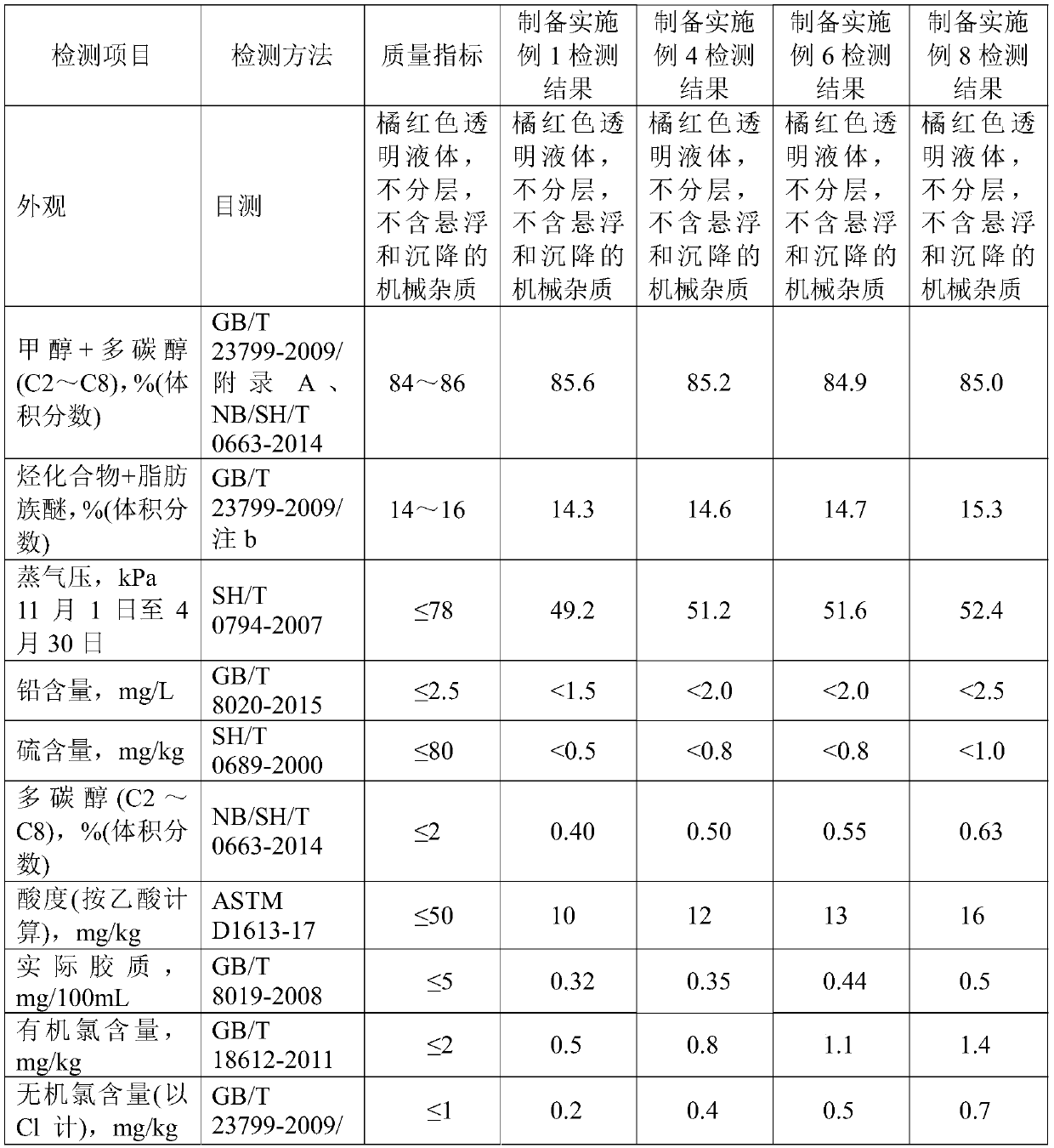

Examples

preparation Embodiment 1

[0041] A preparation method for an alcohol-based fuel composite additive, comprising the following steps,

[0042] (1) Under normal temperature and pressure conditions, first mix 39 parts of base solvent isobutanol, 2 parts of camphor, 9 parts of water-soluble agent sorbitan trioleate, 5 parts of ethanol, and 2 parts of methylal;

[0043] (2) Then add 10 parts of cosolvent methyl tert-butyl ether, 3 parts of ethyl tert-butyl ether, 2 parts of methyl tert-amyl ether, 2 parts of naphtha, 1.5 parts of xylene, 1.5 parts of petroleum ether, 1 part of fatty alcohol polyoxyethylene ether of corrosion inhibitor, 4 parts of alkylated diphenylamine, 3 parts of N,N'-disalicylidene-1,3-diaminopropane, 6 parts of alkenyl succinate, Clean and dispersant polyisobutylene bis-succinimide 2 parts, polyisobutylene polyimide 2 parts, mix uniformly to obtain a mixed reagent;

[0044] (3) Heat the mixed reagent to 45°C, then add 5 parts of corrosion inhibitor benzotriazole, 4 parts of 2,6-di-tert-...

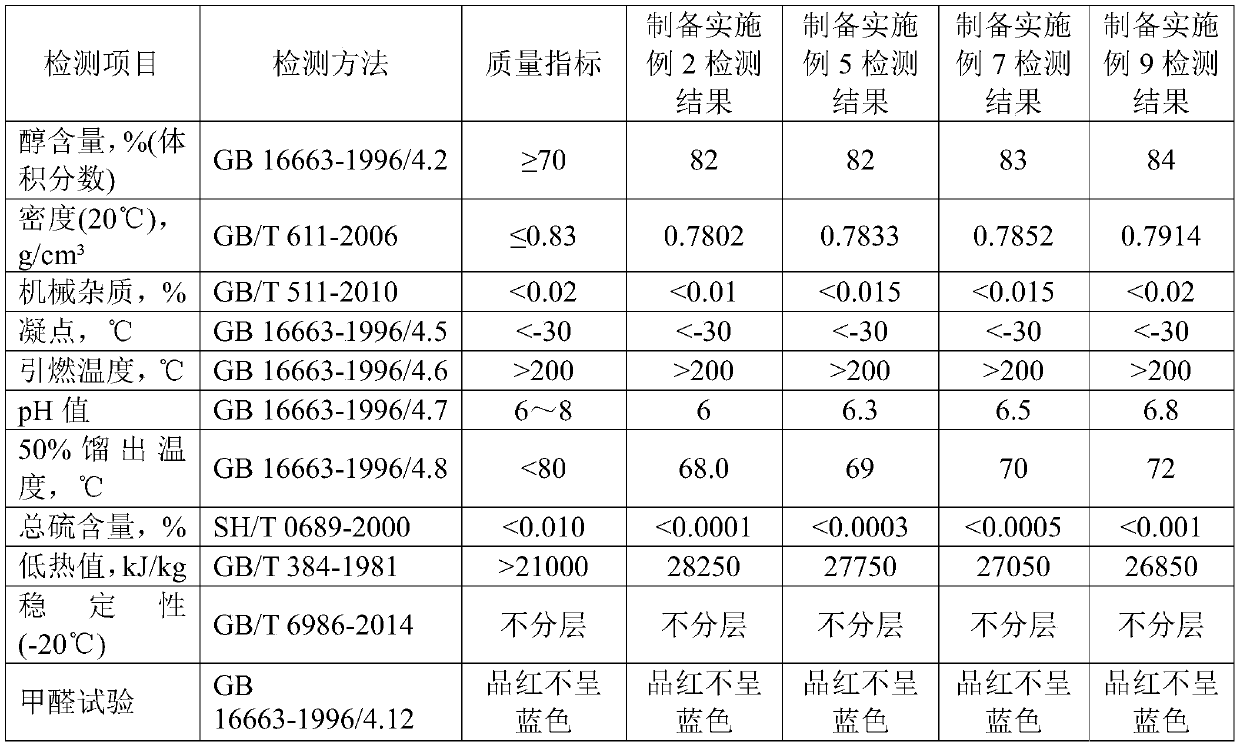

preparation Embodiment 2

[0046] A preparation method for an alcohol-based fuel composite additive, comprising the following steps,

[0047] (1) Under normal temperature and pressure conditions, firstly mix 38 parts of base solvent isobutanol, 3 parts of camphor, 8 parts of water-soluble agent sorbitan trioleate, 6 parts of ethanol, and 1 part of methylal;

[0048] (2) Then add 12 parts of cosolvent methyl tert-butyl ether, 2 parts of ethyl tert-butyl ether, 1 part of methyl tert-amyl ether, 1 part of naphtha, 2 parts of xylene, 1 part of petroleum ether, 2 parts of fatty alcohol polyoxyethylene ether of corrosion inhibitor, 5 parts of alkylated diphenylamine, 2 parts of N,N'-disalicylidene-1,3-diaminopropane, 5 parts of alkenyl succinate, Clean and dispersant polyisobutylene bis-succinimide 3 parts, polyisobutylene polyimide 1 part, mix uniformly to obtain a mixed reagent;

[0049] (3) Heat the mixed reagent to 44°C, then add 7 parts of corrosion inhibitor benzotriazole, 3 parts of 2,6-di-tert-butyl-4-...

preparation Embodiment 3

[0051] A preparation method for an alcohol-based fuel composite additive, comprising the following steps,

[0052] (1) Under normal temperature and pressure conditions, first mix 40 parts of base solvent isobutanol, 1 part of camphor, 10 parts of water-soluble agent sorbitan trioleate, 4 parts of ethanol, and 3 parts of methylal;

[0053] (2) Then add 8 parts of cosolvent methyl tert-butyl ether, 4 parts of ethyl tert-butyl ether, 3 parts of methyl tert-amyl ether, 3 parts of naphtha, 1 part of xylene, 2 parts of petroleum ether, Corrosion inhibitor fatty alcohol polyoxyethylene ether 1 part, alkylated diphenylamine 3 parts, N,N'-disalicylidene-1,3-diaminopropane 4 parts, alkenyl succinate 7 parts, 1 part of polyisobutylene bisuccinimide and 2 parts of polyisobutylene polyimide are mixed uniformly to obtain a mixed reagent;

[0054] (3) Heat the mixed reagent to 46°C, then add 3 parts of corrosion inhibitor benzotriazole, 5 parts of 2,6-di-tert-butyl-4-methylphenol and 1 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com