Carbon inhibitor and application thereof in molybdenum-nickel flotation from high-carbon molybdenum-nickel ores

A technology of inhibitor and molybdenum-nickel ore, which is applied in flotation, solid separation, etc., can solve the problems of increased dosage of molybdenum-nickel flotation agents, complex ore properties, and increased dosage of ore dressing agents, and achieves easy industrial implementation and large-scale Promotion, simple process, and the effect of inhibiting carbonaceous matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

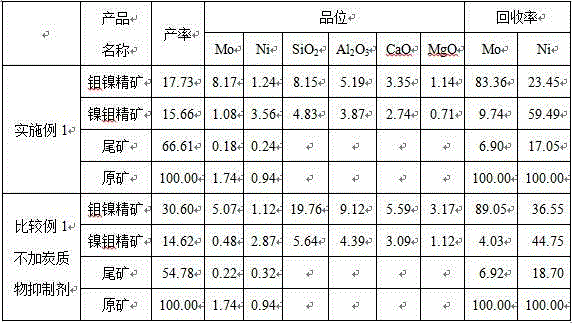

Embodiment 1

[0016] The carbon content of high-carbon molybdenum-nickel ore in a certain place in Cili, Hunan Province is about 6%. It has good floatability and strong adsorption, and the existence of carbonaceous matter greatly affects the flotation of the mine.

[0017] (1) Grinding: Grinding high-carbon molybdenum-nickel ore until the particle size is less than 200 mesh accounts for 72%;

[0018] (2) Molybdenum-nickel flotation: Molybdenum concentrate and molybdenum-nickel flotation tailings are obtained after 1 molybdenum roughing, 3 molybdenum-nickel beneficiation and 2 molybdenum-nickel scavenging; gram of sodium carbonate, 1500 grams of water glass, 240 grams of carbonaceous inhibitors, 90 grams of kerosene, and 96 grams of MIBC. In molybdenum concentration, 60 g / t, 30 g / t and 10 g / t of carbonaceous inhibitors are added to the selection 1, selection 2 and selection 3 respectively; kerosene is added to the molybdenum and nickel selection 1 and scavenging 2 respectively 36 g / t and 1...

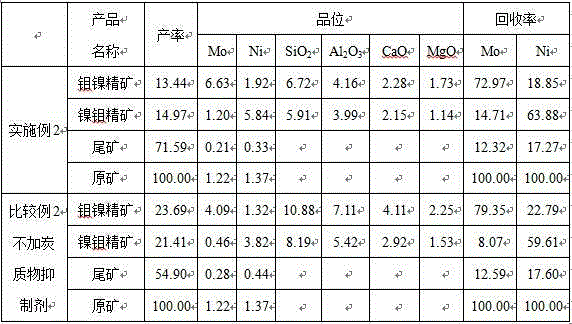

Embodiment 2

[0025] The carbon content of high-carbon molybdenum-nickel ore in a certain place in Guizhou is about 10%. The minerals are closely combined and the carbonaceous content is high.

[0026] (1) Grinding: Grinding high-carbon molybdenum-nickel ore until the particle size is less than 200 mesh accounts for 85%;

[0027] (2) Molybdenum-nickel flotation: Molybdenum-nickel concentrate and molybdenum-nickel flotation tailings are obtained after 2 times of molybdenum-nickel roughing, 3 times of molybdenum-nickel concentration and 2 times of molybdenum sweeping; 600 grams of sodium carbonate, 1800 grams of water glass, 320 grams of carbonaceous substance inhibitors, 120 grams of kerosene, 120 grams of MIBC, and 60 grams of kerosene and 40 grams of MIBC for each ton of raw ore of molybdenum and nickel. In molybdenum and nickel selection, selection 1, selection 2 and selection 3 add carbonaceous inhibitors 80 g / t, 20 g / t and 10 g / t respectively; molybdenum and nickel sweep 1 and sweep 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com