Preparation technology of ethyl tert-butyl ether etherification

A technology for the preparation of ethyl tert-butyl ether, which is applied in the fields of ether preparation, chemical instruments and methods, addition of unsaturated compounds to prepare ether, etc., can solve the problem of aggravating the material consumption and energy consumption of ethyl tert-butyl ether, and affecting the production of ethyl tert-butyl ether. Solve problems such as unsatisfactory product purity, conversion rate and selectivity of tert-butyl ether, achieve the effect of improving conversion rate and selectivity, improving product purity, and reducing ethanol content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

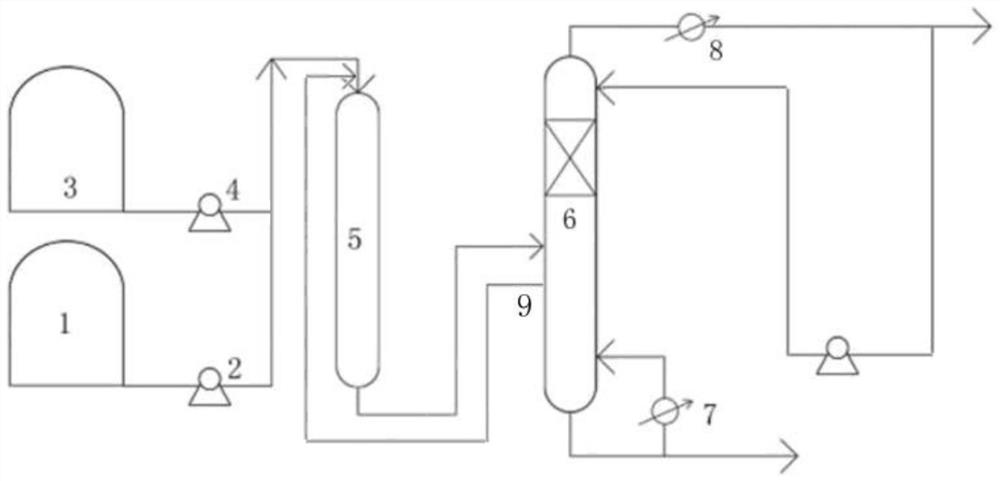

Image

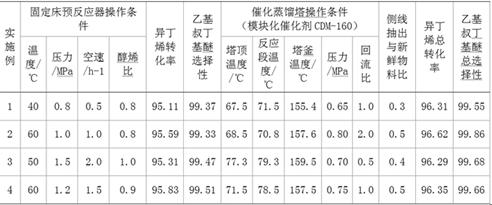

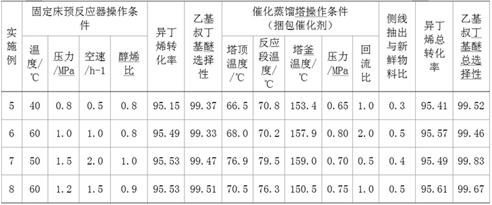

Examples

Embodiment Construction

[0021] The technical content of this patent application will be described in detail below through various embodiments, but the protection scope of this patent application is not limited to the content described in the embodiments. The catalyst used in the preparation process for the etherification of ethyl tert-butyl ether consists of p-tert-butylstyrene and divinylbenzene monomers, which are suspended and copolymerized under the action of porogens and surfactants to obtain copolymer white balls, which are then passed through pores Purified and sulfonated to obtain.

[0022] Catalyst C-1

[0023] In a stainless steel stirred tank equipped with a reflux condensing device, add 2000 g of water and a surfactant, heat with stirring, and completely dissolve to obtain a water phase. When the temperature of the stainless steel stirred tank is raised to 60 ° C, add an oil phase mixed with an organic phase, and then The temperature is 80°C, the stirring speed is 60r / min, the polymeriza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com