Liquid/Liquid Extraction

An extraction, solvent technology, applied in some or all of the fields, that can solve problems such as unacceptable phase separation, negative environmental impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

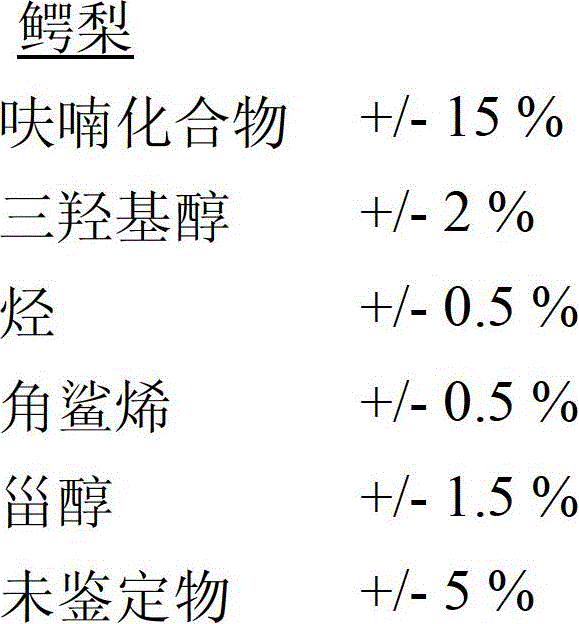

[0114] Example 1: Using DCE to extract avocado unsaponifiables (reference 1)

[0115] The first step consists of the saponification of the concentrate prepared by molecular distillation of avocado oil.

[0116] To this end, a given weight of avocado oil concentrate (45.6 g) was added successively to a 100 ml round bottom flask equipped with a condenser, followed by ethanol (36.6 g), 50% plant ash (5.2 g) and a few pumice stones particles.

[0117] The system was then refluxed for a total of 3.5 hours and, after cooling, diluted with demineralised water (60ml).

[0118] After saponification, a hydro-alcoholic solution is obtained which contains unsaponifiables (or unsaponifiable fractions). The unsaponifiables are then extracted using a first solvent system, specifically DCE.

[0119] Several consecutive extractions (5 x 70 ml) were performed; the collected organic phases were then combined and washed with tap water (5 x 70 ml) until neutral (phenolphthalein test).

[012...

Embodiment 2

[0122] Embodiment 2: Using HMDS to extract avocado unsaponifiables

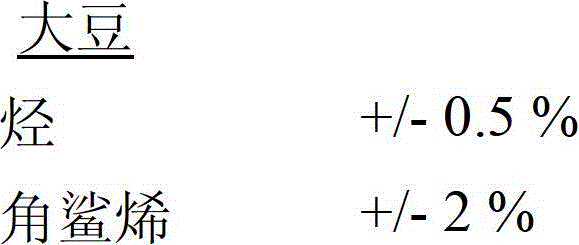

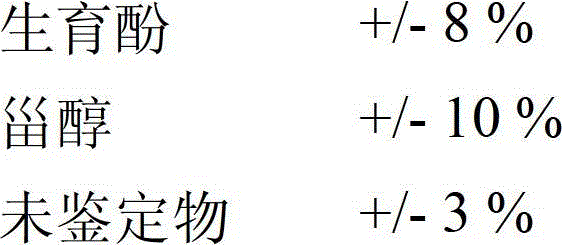

[0123] Extraction was carried out according to the procedure of Example 1. After optimization to adapt it to the new solvent system, the extraction process consisted of an extraction step with 4 x 70 ml of HDMS (instead of DCE) and a step involving washing the organic phase with 3 x 70 ml of water. Measurements were carried out as in Example 1 and the results are shown in Table 1 below.

Embodiment 3

[0124] Example 3: Using HMDS-MeTHF mixture (90 / 10, by volume) to extract avocado unsaponifiables

[0125] Extraction was carried out according to the procedure of Example 1. After optimization to adapt it to the new solvent system, the extraction procedure consisted of extraction steps using 4 x 70 ml of HDMS-MeTHF mixture (90 / 10 by volume) (instead of DCE) and contained 2 x 70 ml The step composition of washing the organic phase with water. Measurements were carried out as in Example 1 and the results are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com