Preparation method of acidic polystyrene resin catalyst for synthesis of ethyl tert-butyl ether

A technology of polystyrene resin and ethyl tert-butyl ether, which is applied in the field of acidic polystyrene resin catalysts, can solve problems such as polluted products, increased side reactions of oligomerization, and easy drop-off of sulfonic acid groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] (1) Preparation of chloromethyl polystyrene resin

[0021] Mix polyvinyl alcohol (3.5g), sodium chloride (10.5g) and deionized water (350ml) to form a homogeneous aqueous solution, then add chloromethylstyrene (12ml), divinylbenzene (4ml), benzene After mixing ethylene (4ml) and toluene (24ml) to form a uniform oil phase, add it to the prepared water phase, and add the initiator azobisisobutylcyanide (1.75g) at the same time. After reacting for 8 hours, the product was washed with water, washed with methanol, Soxhlet extracted with dichloromethane, washed with ethanol, and dried in vacuum to obtain chloromethyl polystyrene resin;

[0022] (2) Preparation of acidic ionic liquid

[0023] React with imidazole (0.1mol) in ethanol (100ml) and 1,3-propane sultone (0.1mol) at 70°C for 12h, filter, wash with ethanol, and dry to obtain a white product. The white product (0.1 mol) was dissolved in deionized water, reacted with concentrated sulfuric acid (0.1 mol) at 60°C for 12...

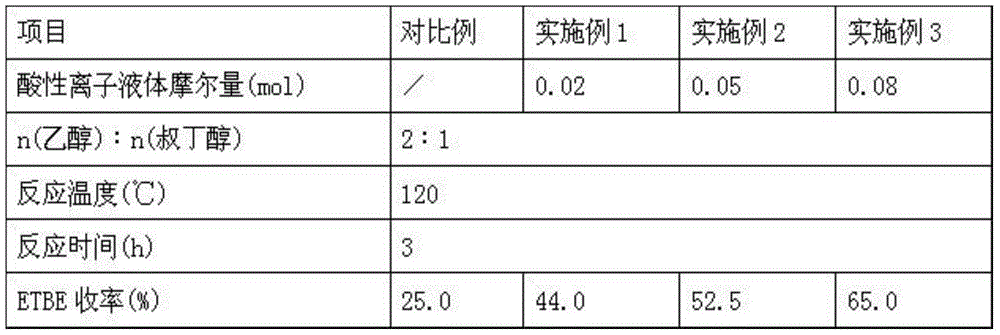

Embodiment 1

[0027] Take 10.5 g of the prepared chloromethyl polystyrene resin, add 0.02 mol of the prepared acidic ionic liquid, and synthesize the acidic polystyrene resin catalyst according to the above steps for the synthesis of ethyl tert-butyl ether. Compared with the comparative example (the catalyst is chloromethyl polystyrene resin), the yield of ethyl tert-butyl ether has increased by 19%.

Embodiment 2

[0029] Take 10.5 g of the prepared chloromethyl polystyrene resin, add 0.05 mol of the prepared acidic ionic liquid, and synthesize the acidic polystyrene resin catalyst according to the above steps for the synthesis of ethyl tert-butyl ether. Compared with the comparative example (the catalyst is chloromethyl polystyrene resin), the yield of ethyl tert-butyl ether is increased by 27.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com