Environment-friendly biological fuel for boilers and preparation method of biological fuel

A kind of bio-fuel and environmental protection technology, applied in the direction of fuel, petroleum industry, fat production, etc., can solve the problems of high production cost of bio-fuel, insufficient combustion of bio-fuel, and unsatisfactory fuel utilization rate, etc., to achieve anti-knock and anti-oxidation Good performance, low production cost, and improved antiknock performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

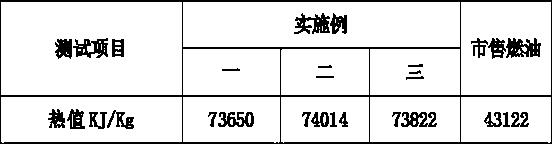

Examples

Embodiment 1

[0020] The environmentally friendly biofuel for boilers proposed by the present invention includes the following raw materials in parts by weight: 60 parts of palm fruit extract, 6 parts of methanol, 6 parts of ethanol, 4 parts of oleic acid, 4 parts of polydimethylsiloxane, hexamethyl 2 parts of cyclotrisiloxane, 1.0 part of dimethyl carbonate, 1.0 part of ethyl tert-butyl ether, 2 parts of stabilizer, 0.4 part of metal corrosion inhibitor, 2 parts of tert-butyl p-hydroxyanisole, propyl gallate 2 servings.

[0021] Its preparation method comprises the following steps:

[0022] S1: Preparation of palm fruit extract. After the fresh palm fruit bunches are sterilized, the palm fruit is peeled off from the fruit bunches, the pulp in the fruit is separated from the core by using a crusher, and the fruit in the core is separated The kernels are separated, and the kernels and pulp are mixed and fed into a masher for crushing, and then the oil in the kernels and pulp is squeezed out...

Embodiment 2

[0026] The environmentally friendly biofuel for boilers proposed by the present invention comprises the following raw materials in parts by weight: 80 parts of palm fruit extract, 4 parts of methanol, 4 parts of ethanol, 6 parts of oleic acid, 6 parts of polydimethylsiloxane, hexamethyl 2 parts of cyclotrisiloxane, 0.2 part of dimethyl carbonate, 0.3 part of ethyl tert-butyl ether, 2 parts of stabilizer, 0.6 part of metal corrosion inhibitor, 2 parts of lauryl gallate.

[0027] Its preparation method comprises the following steps:

[0028] S1: Preparation of palm fruit extract. After the fresh palm fruit bunches are sterilized, the palm fruit is peeled off from the fruit bunches, the pulp in the fruit is separated from the core by using a crusher, and the fruit in the core is separated The kernels are separated, and the kernels and pulp are mixed and fed into a masher for crushing, and then the oil in the kernels and pulp is squeezed out through a screw press process, and the ...

Embodiment 3

[0032] The environmentally friendly biofuel for boilers proposed by the present invention comprises the following raw materials in parts by weight: 50 parts of palm fruit extract, 3 parts of methanol, 5 parts of ethanol, 6 parts of oleic acid, 6 parts of polydimethylsiloxane, hexamethyl 1 part of cyclotrisiloxane, 2.0 parts of dimethyl carbonate, 1.0 part of ethyl tert-butyl ether, 3 parts of stabilizer, 0.4 parts of metal corrosion inhibitor, 4 parts of 2,6-di-tert-butyl-p-cresol.

[0033] Its preparation method comprises the following steps:

[0034] S1: Preparation of palm fruit extract. After the fresh palm fruit bunches are sterilized, the palm fruit is peeled off from the fruit bunches, the pulp in the fruit is separated from the core by using a crusher, and the fruit in the core is separated The kernels are separated, and the kernels and pulp are mixed and fed into a masher for crushing, and then the oil in the kernels and pulp is squeezed out through a screw press proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com