Energy-saving emission-reducing gasoline additive and preparation method and application thereof

A gasoline additive, energy-saving and emission-reduction technology, applied in the direction of fuel additives, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems of air and water pollution, groundwater pollution, poor environmental performance, etc., to reduce harm and reduce evaporation loss , maintain a strong and powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

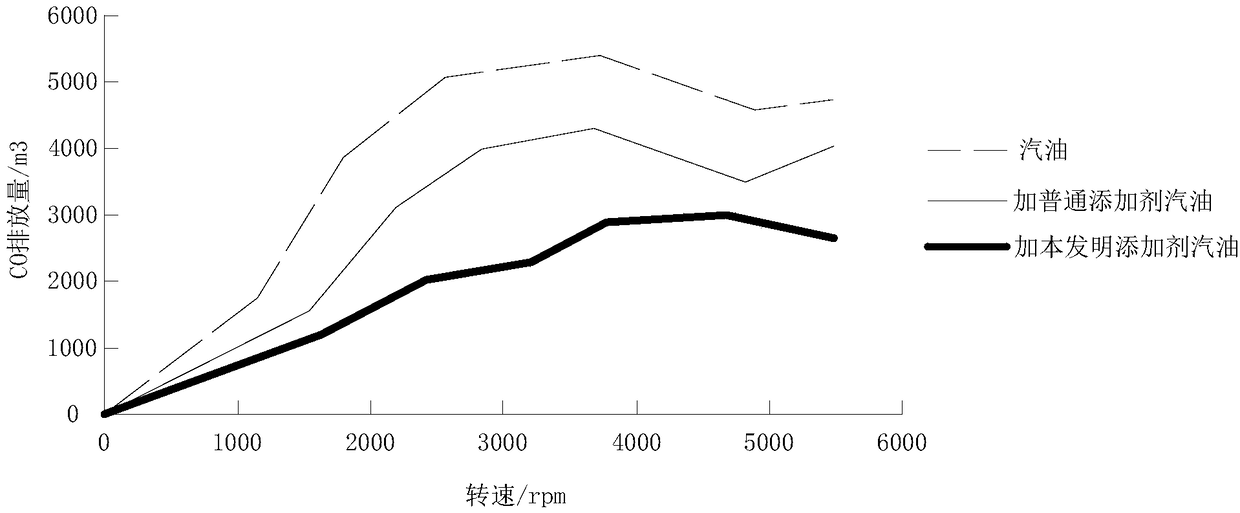

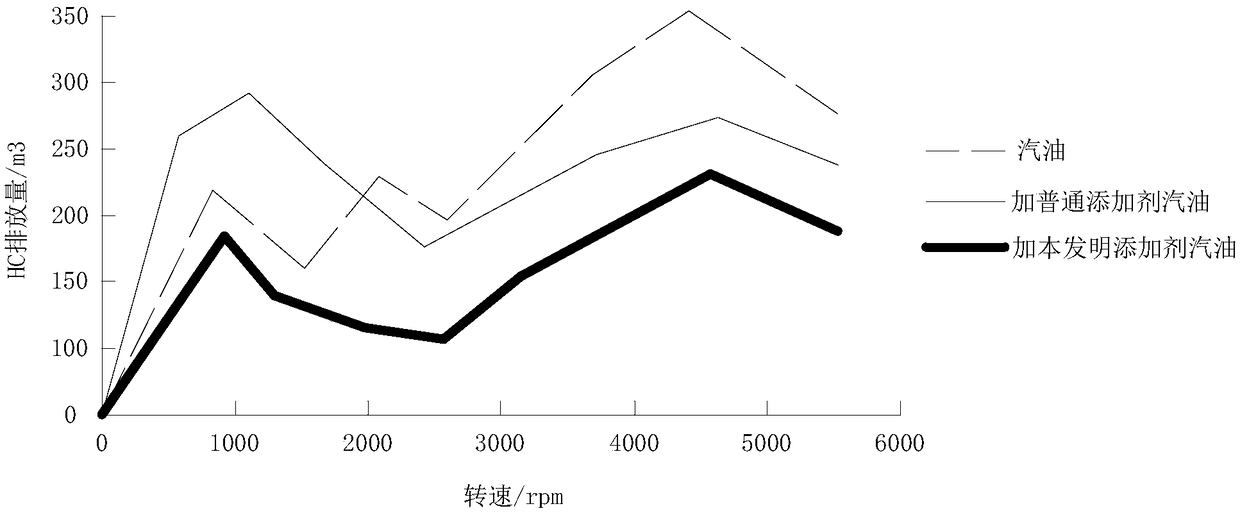

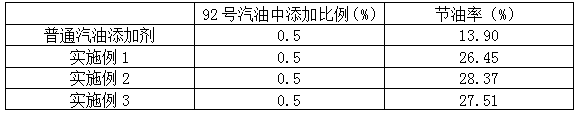

Examples

Embodiment 1

[0049] Under normal temperature conditions, weigh 15kg of denatured fuel ethanol and put it into a container, then slowly add 10kg of butanol, 5kg of isopropanol and 10kg of toluene into the container, evacuate the oxygen in the container, and stir the solution in the container evenly. 10 minutes to obtain mixed solution A; 8kg ethyl tert-butyl ether was added to mixed solution A, stirred evenly for 10 minutes, and left to react for 10 minutes to obtain mixed solution B; in 5kg paraffin solution Add 3kg of carbon fatty alcohol polyoxyethylene ether and 2kg of bis-(3-triethoxysilylpropyl)-tetrasulfide, stir evenly, and the stirring time is 10 minutes. After standing for 5 minutes, add the reaction solution to the mixing In liquid B, mixed liquid C was obtained; 1 kg of ethyl nitrate and 1 kg of isooctyl nitrate were mixed and stirred, then added to mixed liquid C, stirred evenly, and 2 kg of polyoxyethylene sorbitan fatty acid ester was weighed and added to the stirred In the f...

Embodiment 2

[0051] Under normal temperature conditions, weigh 25kg of denatured fuel ethanol and put it into a container, then slowly add 18kg of butanol, 10kg of isopropanol and 20kg of toluene into the container, evacuate the oxygen in the container, and stir the solution in the container evenly. Mixed solution A was obtained for 15 minutes; 11kg of ethyl tert-butyl ether was added to mixed solution A, stirred evenly for 15 minutes, and left to react for 15 minutes to obtain mixed solution B; in 10kg of paraffin solution Add 6kg of carbon fatty alcohol polyoxyethylene ether and 5kg of bis-(3-triethoxysilylpropyl)-tetrasulfide, stir evenly, and the stirring time is 15 minutes. After standing for 8 minutes, add the reaction solution to the mixing In liquid B, mixed liquid C was obtained; 3kg ethyl nitrate and 3kg isooctyl nitrate were mixed and stirred, then added to mixed liquid C, stirred evenly, and 4kg polyoxyethylene sorbitan fatty acid ester was weighed and added to the stirred In t...

Embodiment 3

[0053] Under normal temperature conditions, weigh 35kg of denatured fuel ethanol and put it into a container, then slowly add 25kg of butanol, 15kg of isopropanol and 30kg of toluene into the container, evacuate the oxygen in the container, and stir the solution in the container evenly. Mixed solution A was obtained for 20 minutes; 15kg of ethyl tert-butyl ether was added to mixed solution A, stirred evenly for 20 minutes, and left to react for 20 minutes to obtain mixed solution B; in 15kg of paraffin solution Add 10kg of carbon fatty alcohol polyoxyethylene ether and 8kg of bis-(3-triethoxysilylpropyl)-tetrasulfide, stir evenly, and the stirring time is 20 minutes. After standing for 10 minutes, add the reaction solution to the mixing In solution B, mixed solution C was obtained; 5kg ethyl nitrate and 5kg isooctyl nitrate were mixed and stirred, then added to mixed solution C, stirred evenly, and 8kg polyoxyethylene sorbitan fatty acid ester was weighed and added to the stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com