Polyether amine, production method thereof and application of polyether amine in methanol gasoline

A technology of methanol gasoline and polyether amine, which is applied in chemical instruments and methods, petroleum industry, preparation of organic compounds, etc. It can solve the problems of complex production process, high cost, low efficiency, etc., and achieve the improvement of market competitiveness and performance , the effect of preventing air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

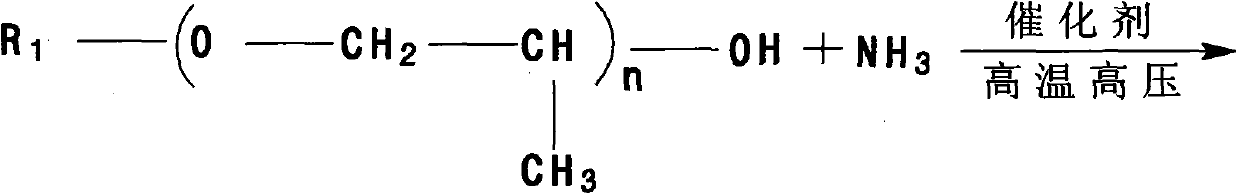

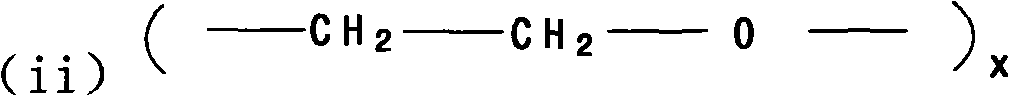

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1 M10 methanol gasoline

[0065] Under normal temperature, normal pressure, non-spark static electricity, explosion-proof operating conditions:

[0066] Will meet the national standard "GB / T 23510-2009" vehicle fuel methanol standard (according to weight) methanol 10%, 90# national standard gasoline 80.7%, butanol 2%, 200# solvent naphtha 7%, the polymer of the present invention 0.2% ether amine, 0.1% compound additive containing a small amount of MMT, anti-corrosion agent, anti-swelling agent, antioxidant, and detergent. After mixing, the pump circulates for 2 hours, and it can be used after standing for 48 hours.

[0067] After testing:

[0068] 1. Octane number 94.2.

[0069] 2. Reid method saturated vapor pressure 64kPa.

[0070] 3. The ability of miscibility and water resistance (under the temperature of 30°C in summer) is: adding 1% water will not be turbid or stratified, and the required goal will be achieved.

[0071] 4. After six months of storag...

Embodiment 2

[0072] Embodiment 2 M15 methanol gasoline

[0073] Under normal temperature, normal pressure, non-spark static electricity, explosion-proof operating conditions:

[0074] Will meet the national standard "GB / T 23510-2009" vehicle fuel methanol standard (according to weight) methanol 15%, 90# national standard gasoline 74.41%, butanol 2.2%, 200# solvent naphtha 8%, the polymer of the present invention Ether amine 0.29%, compound additive containing a small amount of MMT, anti-corrosion agent, anti-swelling agent, antioxidant, and detergent 0.1%, after mixing, the pump circulates for 2 hours, and it can be used after standing for 48 hours.

[0075] After testing:

[0076] 1. Octane number 94.7.

[0077] 2. Reid method saturated vapor pressure 63kPa.

[0078] 3. The ability of miscibility and water resistance (at 30°C) is: add 1.2% water without turbidity or stratification, and meet the required goals.

[0079] 4. After six months of storage, no acidic substances were detected...

Embodiment 3

[0080] Example 3 M20 methanol gasoline

[0081] Under normal temperature, normal pressure, non-spark static electricity, explosion-proof operating conditions:

[0082] 20% methanol, 69.85% 90# national standard gasoline, 2.7% butanol, C 9 7% aromatic hydrocarbons, 0.35% polyetheramine according to the present invention, 0.1% compound additives containing a small amount of MMT, anti-corrosion agent, anti-swelling agent, antioxidant, and detergent. After mixing, the pump circulates for 2 hours and stands still for 48 hours. use.

[0083] After testing:

[0084] 1. Octane number 95.1.

[0085] 2. Reid method saturated vapor pressure 62kPa.

[0086] 3. The ability of miscibility and water resistance (at 30°C) is: add 1.3% water without turbidity or stratification, and meet the required goals.

[0087] 4. After six months of storage, no acidic substances were detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com