Oil-gas mixed convey pumping set for oil field

An oil-gas mixed transport pump and mixed transport pump technology, which is applied in transportation and packaging, liquid distribution, transport or transfer devices, special distribution devices, etc., can solve problems such as inability to recover natural gas, waste resources, and reduce economic benefits, and achieve good results. Economic and social benefits, improving efficiency and safety performance, and improving the effect of inhalation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

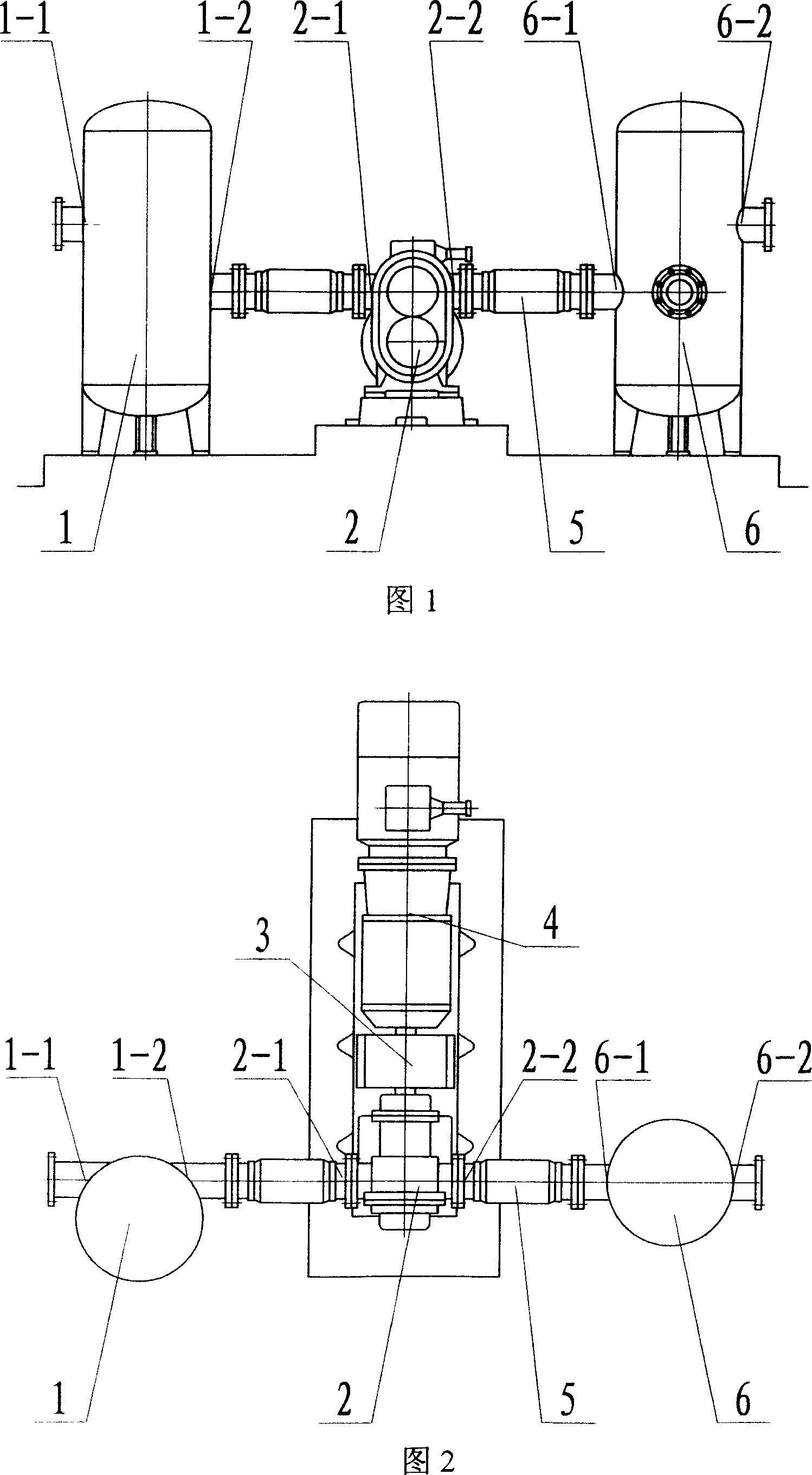

[0013] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing and embodiment:

[0014] The present invention is mainly composed of an oil-gas surge tank 1, a mixing pump 2, a coupling 3, an explosion-proof deceleration motor 4, an oil pipe 5, and an external mixing tank 6; the mixing pump 2 passes through the coupling 3 with a protective cover Connect with the explosion-proof geared motor 4 to obtain power, and be fixed on the foundation together. The oil-gas surge tank 1 is placed at the front end of the inlet 2--1 of the mixed transport pump 2, and the tank body of the oil-gas surge tank 1 is provided with inlet and outlet 1--1 and 1--2 along the tangential direction, and its inlet 1--1 is higher than outlet 1--2; in order to facilitate assembly, connecting short pipes and connecting flanges are provided at inlet and outlet 1-1 and 1--2. Outbound mixed transportation tank 6 is placed at the rear end of the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com