Microbubble photobioreactor for economic microalga cultivation

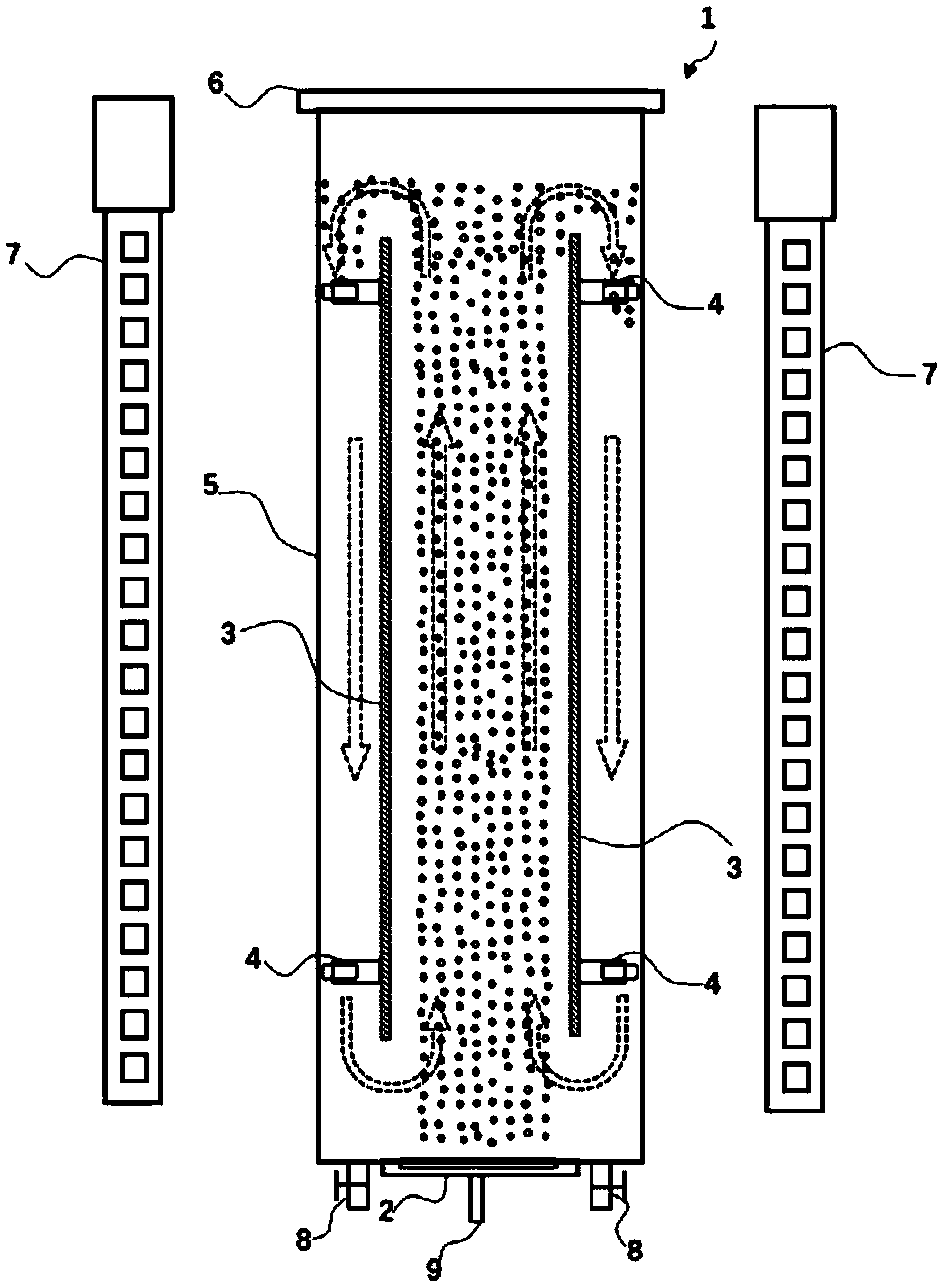

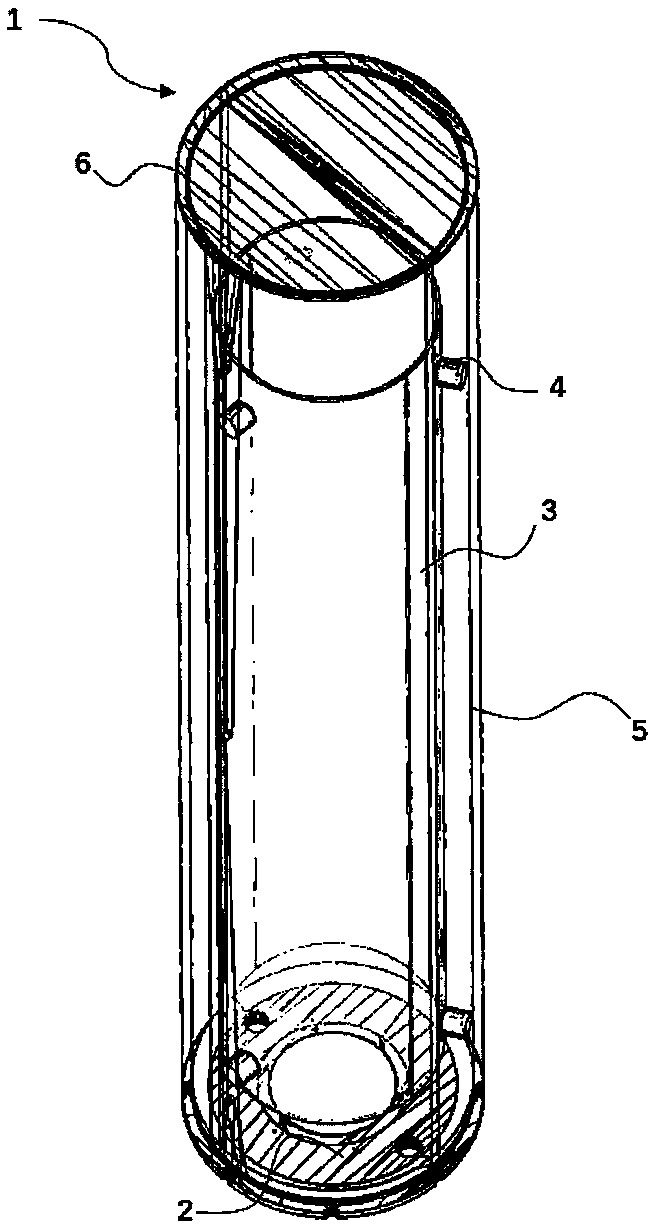

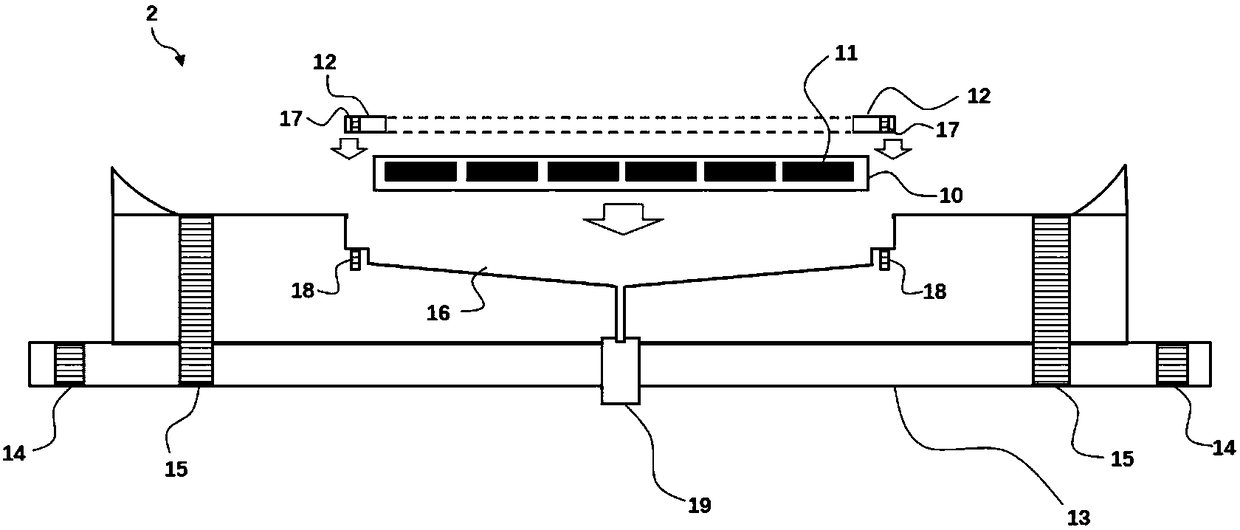

A technology of photobioreactor and microalgae cultivation, applied in the field of microbubble photobioreactor, can solve the problems of ignoring microbubble high-efficiency momentum conduction, maintenance cost, energy consumption cost, high construction cost, and insufficient supply, etc. Energy utilization and photosynthetic efficiency, reducing process complexity and maintenance costs, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] As shown in Fig. 5 (a) and Fig. 5 (b), in the present embodiment, adopt 4 kinds of microporous ceramic diaphragms with different apertures to form the microbubble photobioreactor, the particle size distribution and the Mass transfer performance was tested.

[0051] As shown in Fig. 5(a), it is the particle size distribution result of the microbubble photobioreactor. In 500ml culture medium, take 50mlmin -1 Flow rate into 1% concentration of CO 2 The mixed gas is sent to the microbubble generator composed of 4 kinds of microporous ceramic membranes (Type1, Type2, Type3, Type4) with different pore sizes, and the average particle size of the generated microbubbles is d 32 They are 554 μm, 464 μm, 333 μm and 115 μm, respectively. Among them, the microbubbles produced by the Type1 ceramic diaphragm are relatively large, and about 30% of the microbubbles have a particle size of 400-500um, which can be used for the pre-cultivation of most economical microalgae or pre-cultiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com