Ethanol-water separation method

A technology for ethanol and water-containing ethanol, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of poor separation effect and difficult water separation, achieve obvious dehydration effect, improve treatment effect, and improve operation. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

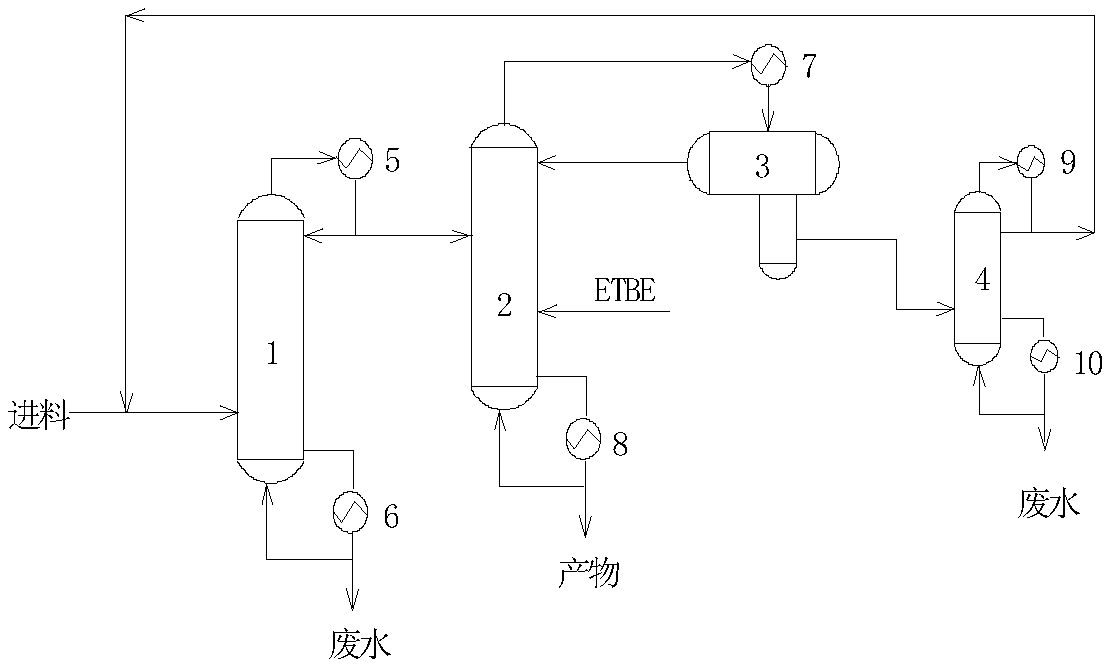

[0073] The low-concentration ethanol aqueous solution that mass percent is about 5% joins in the ethanol concentration tower with the speed of 540g / min, adds about 0.6% ethanol with the speed of 3.5g / min simultaneously, 3.7%ETBE (massfraction, remaining part is water) circulating fluid. The plate number of the ethanol concentration tower is 16, and the reflux ratio is 2:1; the temperature at the top of the concentration tower is 76.3°C.

[0074] The ethanol concentrated liquid with a flow rate of 72.2 g / min and a purity of 77.6% (mass fraction) is obtained, and enters the azeotropic rectification tower, and the temperature at the top of the azeotropic rectification tower is controlled to be 65.5° C. The number of trays in the azeotropic rectification column is 22, and the flow rate of the added ETBE is 0.47g / min; the azeotrope obtained at the top of the tower is condensed and enters the separatory tank.

[0075] The liquid separation tank is operated under normal pressure, an...

Embodiment 2

[0077] The low-concentration ethanol aqueous solution that mass percent is about 5% joins in the ethanol concentration tower with the speed of 540g / min, adds about 0.6% ethanol with the speed of 3.5g / min simultaneously, 3.7%ETBE (massfraction, remaining part is water) circulating fluid. The plate number of the ethanol concentration tower is 16, and the reflux ratio is 5:2; the temperature at the top of the concentration tower is 76.0°C.

[0078] The ethanol concentrated liquid with a flow rate of 61.9 g / min and a purity of 80.3% (mass fraction) is obtained, and enters the azeotropic rectification tower, and the temperature at the top of the azeotropic rectification tower is controlled to be 65.5° C. The number of trays in the azeotropic rectification column is 22, and the flow rate of the added ETBE is 0.33g / min; the azeotrope obtained at the top of the tower is condensed and enters the separatory tank.

[0079] The liquid separation tank is operated under normal pressure, an...

Embodiment 3

[0081] The low-concentration ethanol aqueous solution that mass percent is about 5% joins in the ethanol concentration tower with the speed of 540g / min, adds about 0.6% ethanol with the speed of 3.5g / min simultaneously, 3.7%ETBE (massfraction, remaining part is water) circulating fluid. The plate number of the ethanol concentration tower is 16, and the reflux ratio is 3:1; the temperature at the top of the concentration tower is 75.7°C.

[0082] The ethanol concentrated liquid with a flow rate of 54.2 g / min and a purity of 83.6% (mass fraction) is obtained, and enters the azeotropic rectification tower, and the temperature at the top of the azeotropic rectification tower is controlled to be 65.5° C. The number of trays in the azeotropic rectification column is 22, and the flow rate of the added ETBE is 0.18 g / min; the azeotrope obtained at the top of the tower is condensed and enters the separatory tank.

[0083] The liquid separation tank is operated under normal pressure, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com