A kind of environment-friendly gasoline additive and preparation method thereof

A gasoline additive and additive technology, applied in the field of gasoline additives, can solve the problems of fuel stratification, poor comprehensive performance, and environmental pollution, and achieve the effects of inhibiting carbon deposition, reducing environmental pollution, and overcoming poor high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

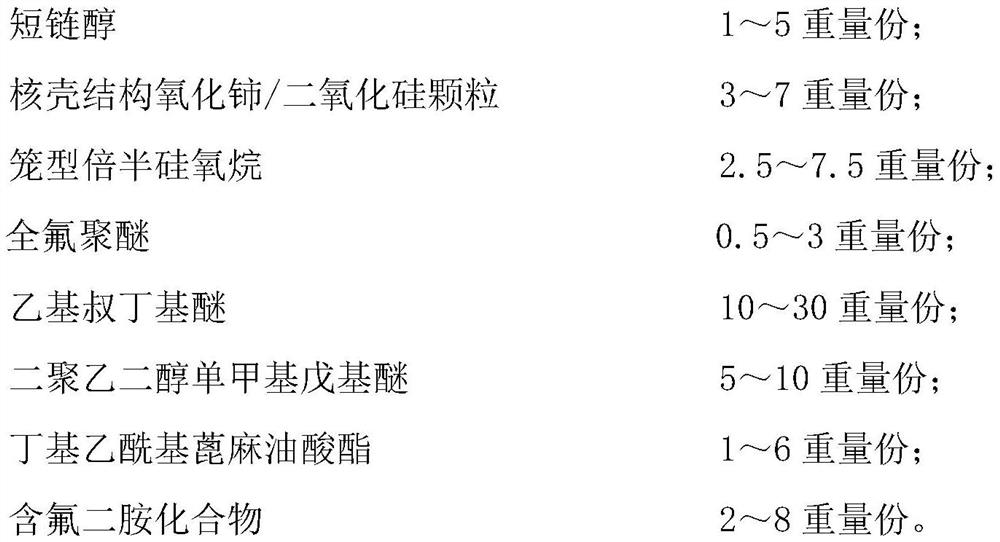

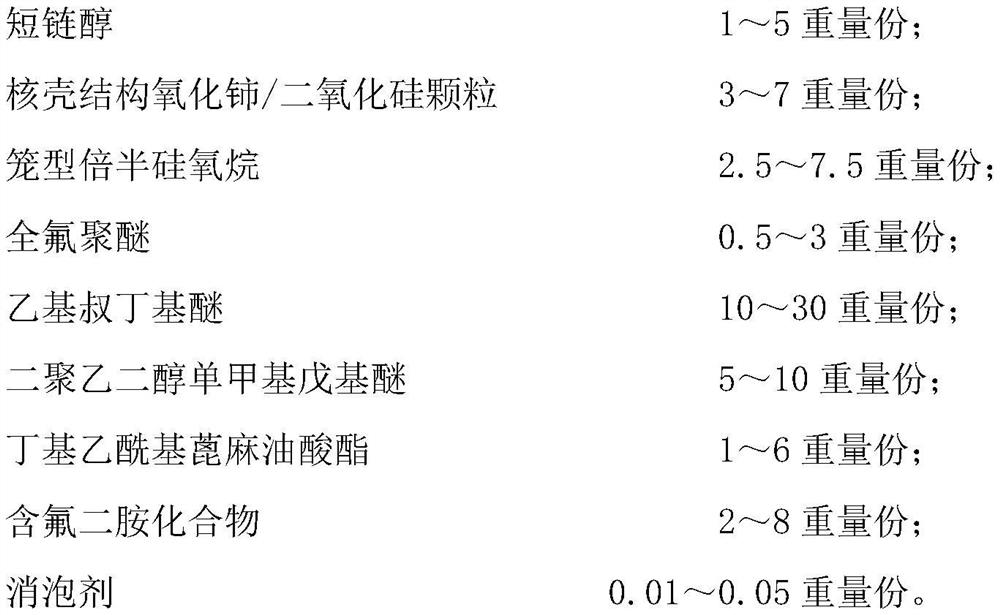

[0034] A kind of environment-friendly gasoline additive, described additive is made up of the raw material of following parts by weight:

[0035] 3 parts by weight of short-chain alcohols;

[0036] 5 parts by weight of core-shell structure cerium oxide / silicon dioxide particles;

[0037] 5 parts by weight of cage silsesquioxane;

[0038] 1.5 parts by weight of perfluoropolyether;

[0039] 20 parts by weight of ethyl tert-butyl ether;

[0040] Dipolyethylene glycol monomethyl amyl ether 7 parts by weight;

[0041] 3 parts by weight of butyl acetyl ricinoleate;

[0042] 4 parts by weight of fluorine-containing diamine compound.

[0043] The short-chain alcohol is a mixture of methanol and isopropanol with a mass ratio of 1:1.

[0044] The core layer of the core-shell structure cerium oxide / silicon dioxide particles is cerium oxide, and the shell layer is silicon dioxide. The preparation method is: dissolving and dispersing 0.5 parts by weight of sodium silicate in 10 parts...

Embodiment 2

[0051] A kind of environment-friendly gasoline additive, described additive is made up of the raw material of following parts by weight:

[0052] 1 part by weight of short-chain alcohol;

[0053] 3 parts by weight of core-shell structure cerium oxide / silicon dioxide particles;

[0054]2.5 parts by weight of cage silsesquioxane;

[0055] 0.5 parts by weight of perfluoropolyether;

[0056] 10 parts by weight of ethyl tert-butyl ether;

[0057] 5 parts by weight of dipolyethylene glycol monomethyl amyl ether;

[0058] 1 part by weight of butyl acetyl ricinoleic acid ester;

[0059] 2 parts by weight of fluorine-containing diamine compound.

[0060] The short-chain alcohol is a mixture of ethanol and butanol with a mass ratio of 1:1.5.

[0061] The core layer of the core-shell structure cerium oxide / silicon dioxide particle is cerium oxide, and the shell layer is silicon dioxide. The preparation method is as follows: 1 weight part of sodium silicate is dissolved and disperse...

Embodiment 3

[0068] A kind of environment-friendly gasoline additive, described additive is made up of the raw material of following parts by weight:

[0069] 5 parts by weight of short-chain alcohols;

[0070] 7 parts by weight of core-shell structure cerium oxide / silicon dioxide particles;

[0071] 7.5 parts by weight of cage silsesquioxane;

[0072] 3 parts by weight of perfluoropolyether;

[0073] 30 parts by weight of ethyl tert-butyl ether;

[0074] Dipolyethylene glycol monomethyl amyl ether 10 parts by weight;

[0075] 6 parts by weight of butyl acetyl ricinoleate;

[0076] 8 parts by weight of fluorine-containing diamine compound.

[0077] The short-chain alcohol is a mixture of propanol and isobutanol with a mass ratio of 1:2.

[0078] The core layer of the core-shell structure cerium oxide / silicon dioxide particle is cerium oxide, and the shell layer is silicon dioxide. The preparation method is as follows: 2 parts by weight of sodium silicate are dissolved and dispersed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com