A modified methanol fuel for vehicles used in a methanol/diesel co-combustion system

A combustion system and methanol technology, applied in the field of compression combustion engine fuel, can solve the problems of insufficient combustion of methanol, insufficient air mixing, and increase in unconventional emissions, and achieve improved lubricity, atomization, and combustion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]A modified fuel methanol for vehicles used in a methanol / diesel co-combustion system, which consists of the following components in terms of mass percentage: 96% methanol, 4% composite modifier;

[0031] The composite modifier is composed of the following components in terms of mass percentage: pentane 20%, ETBE 15%, methylal 21%, tetrameric ricinoleic acid ester 18%, acetone 15%, tert-butyl acetate 10.2% , N-phenyl-α-naphthylamine 0.2%, octyldiphenylamine 0.3%, N,N'-disalicylidenediamine 0.3%.

[0032] The components are simply mixed according to the ratio to prepare vehicle modified fuel methanol I suitable for summer use.

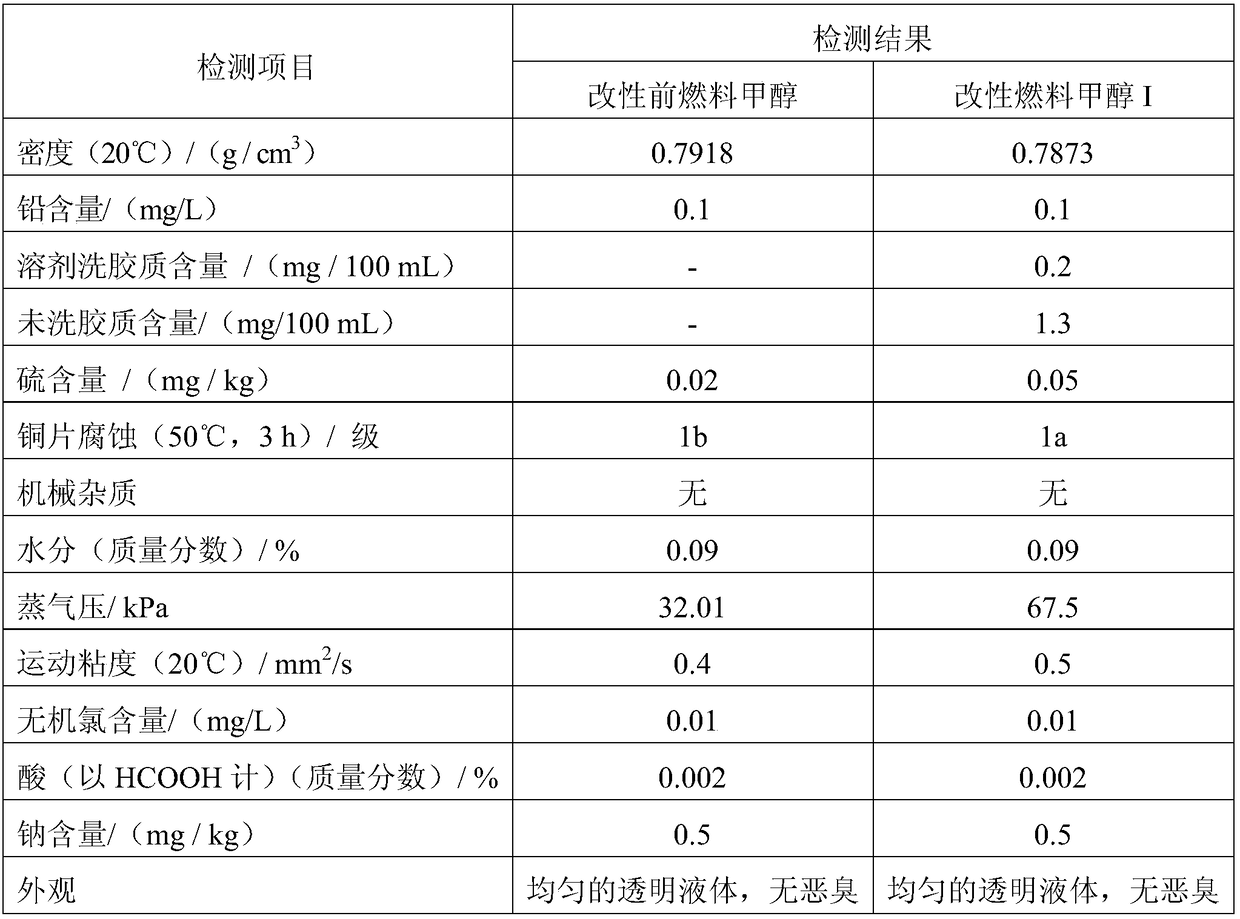

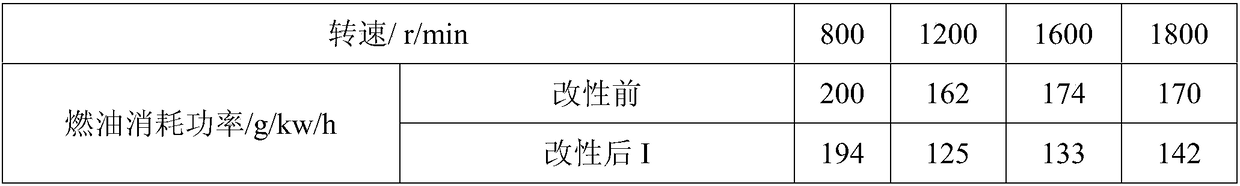

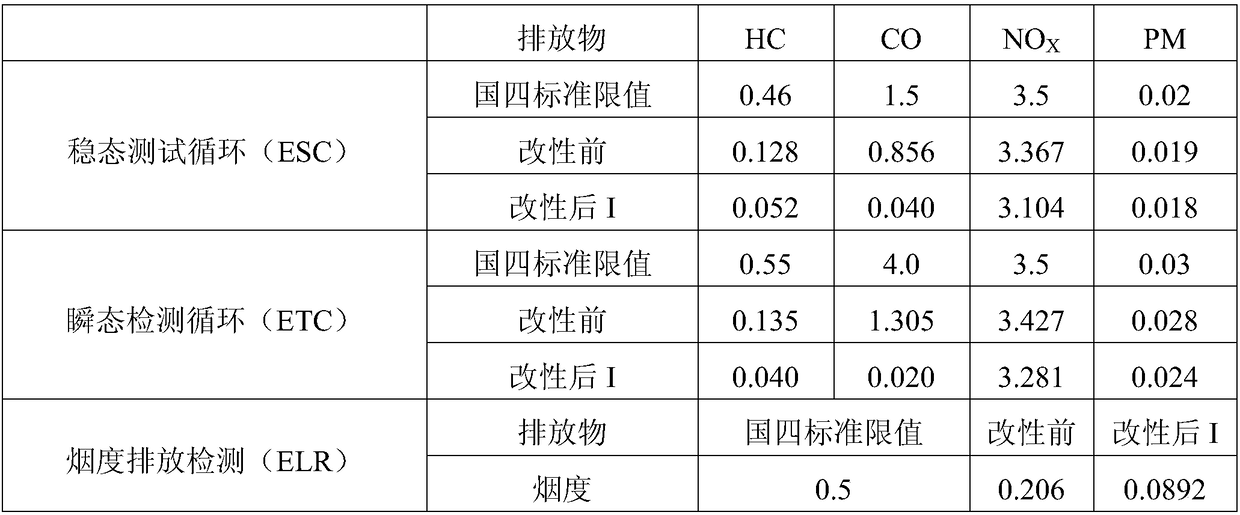

[0033] Carry out routine performance test to modified fuel methanol I and unmodified fuel methanol, the results are shown in Table 1:

[0034] Table 1. Comparison of conventional performance test results of fuel methanol before and after modification

[0035]

[0036] It can be seen from Table 1 that the modified fuel methanol I has obvious ch...

Embodiment 2

[0045] A modified fuel methanol for vehicles used in a methanol / diesel co-combustion system, which consists of the following components in terms of mass percentage: 95% methanol, 5% composite modifier;

[0046] The composite modifier is composed of the following components in terms of mass percentage: pentane 36%, ETBE 12%, methylal 17%, tetrameric ricinoleic acid ester 14%, acetone 12%, tert-butyl acetate 8.5% , N-phenyl-α-naphthylamine 0.1%, octyldiphenylamine 0.2%, N,N'-disalicylidenediamine 0.2%.

[0047] The components are simply mixed according to the ratio to prepare vehicle modified fuel methanol II suitable for use in spring and autumn.

[0048] Carry out routine performance test to modified fuel methanol II and unmodified fuel methanol, the results are shown in Table 4:

[0049] Table 4. Comparison of conventional performance test results of fuel methanol before and after modification

[0050]

[0051] It can be seen from Table 5 that the modified fuel methanol ...

Embodiment 3

[0060] A modified fuel methanol for vehicles used in a methanol / diesel co-combustion system, which consists of the following components in terms of mass percentage: 94% methanol, 6% composite modifier;

[0061] The composite modifier is composed of the following components in terms of mass percentage: pentane 50%, ETBE 9%, methylal 14%, tetrameric ricinoleic acid ester 10%, acetone 9%, tert-butyl acetate 7.7% , N-phenyl-α-naphthylamine 0.1%, octyldiphenylamine 0.1%, N,N'-disalicylidenediamine 0.1%.

[0062] The components are simply mixed according to the ratio to prepare vehicle modified fuel methanol III suitable for winter use.

[0063] Carry out routine performance test to modified fuel methanol III and unmodified fuel methanol, the results are shown in Table 7:

[0064] Table 7. Comparison of conventional performance test results of fuel methanol before and after modification

[0065]

[0066]

[0067] It can be seen from Table 7 that the modified fuel methanol II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com