Preparation of multi-stage structured hydrotalcite and application of multi-stage structured hydrotalcite in gasbarrier packaging material

A technology of structural water and hydrotalcite, applied in chitin polysaccharide coatings, polyether coatings, hyaluronic acid coatings, etc., can solve the problems affecting the barrier properties of packaging materials, difficult to inhibit the diffusion of oxygen molecules, and weak interaction forces. Achieve environmental protection and sustainable development, wide practicability and promotion value, good mechanical properties and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

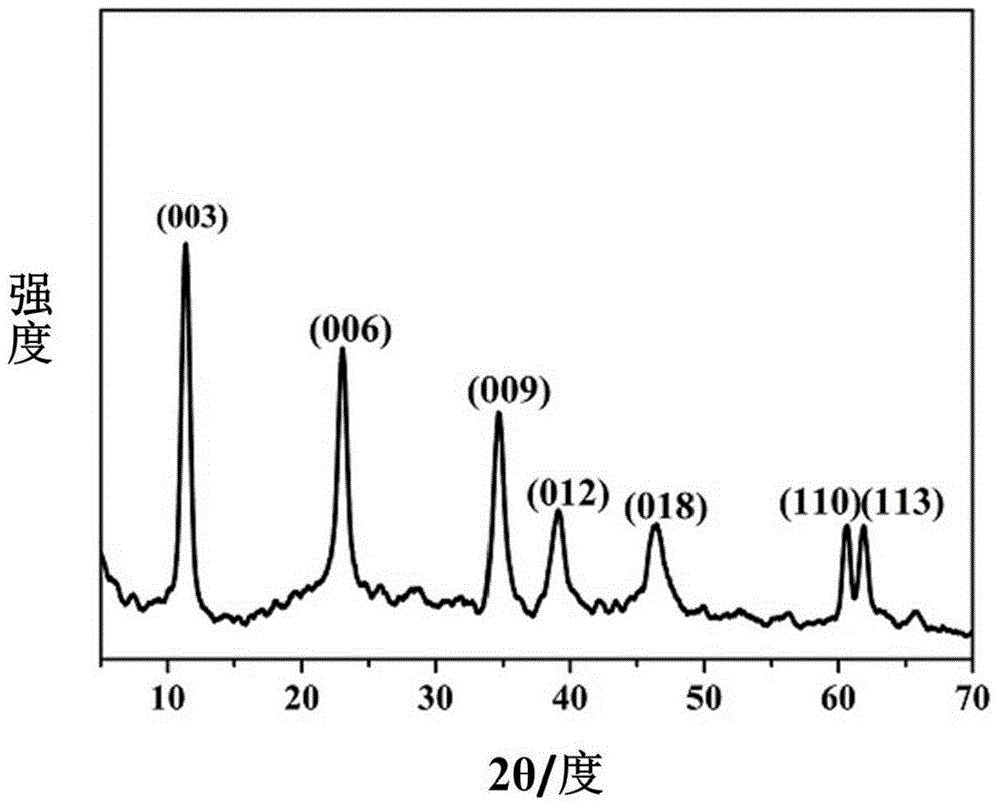

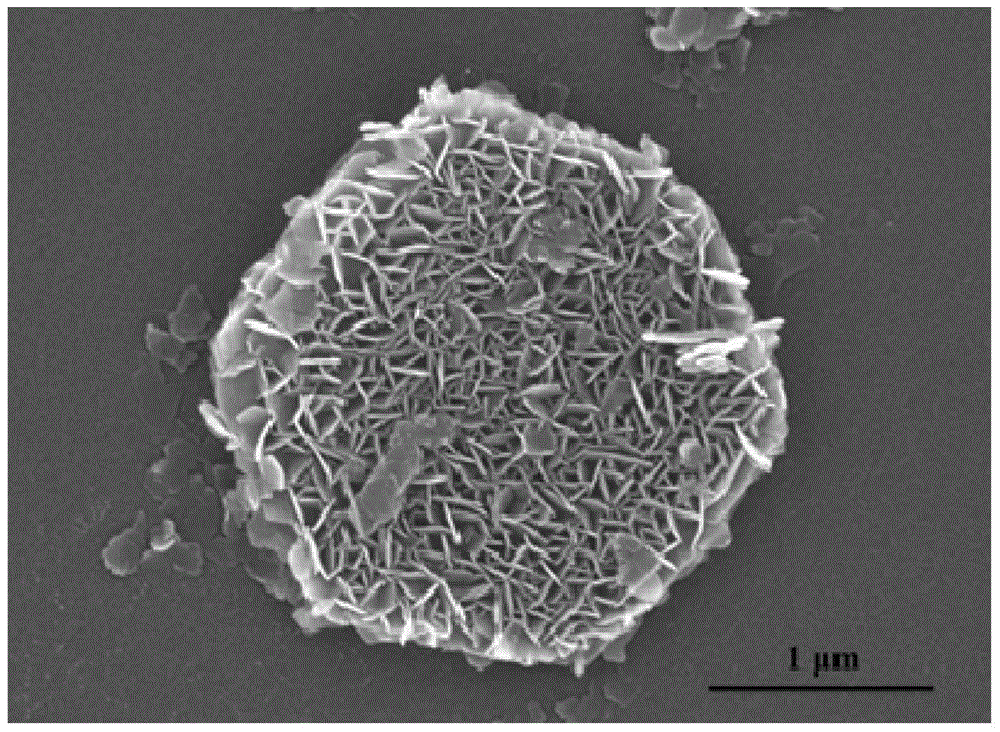

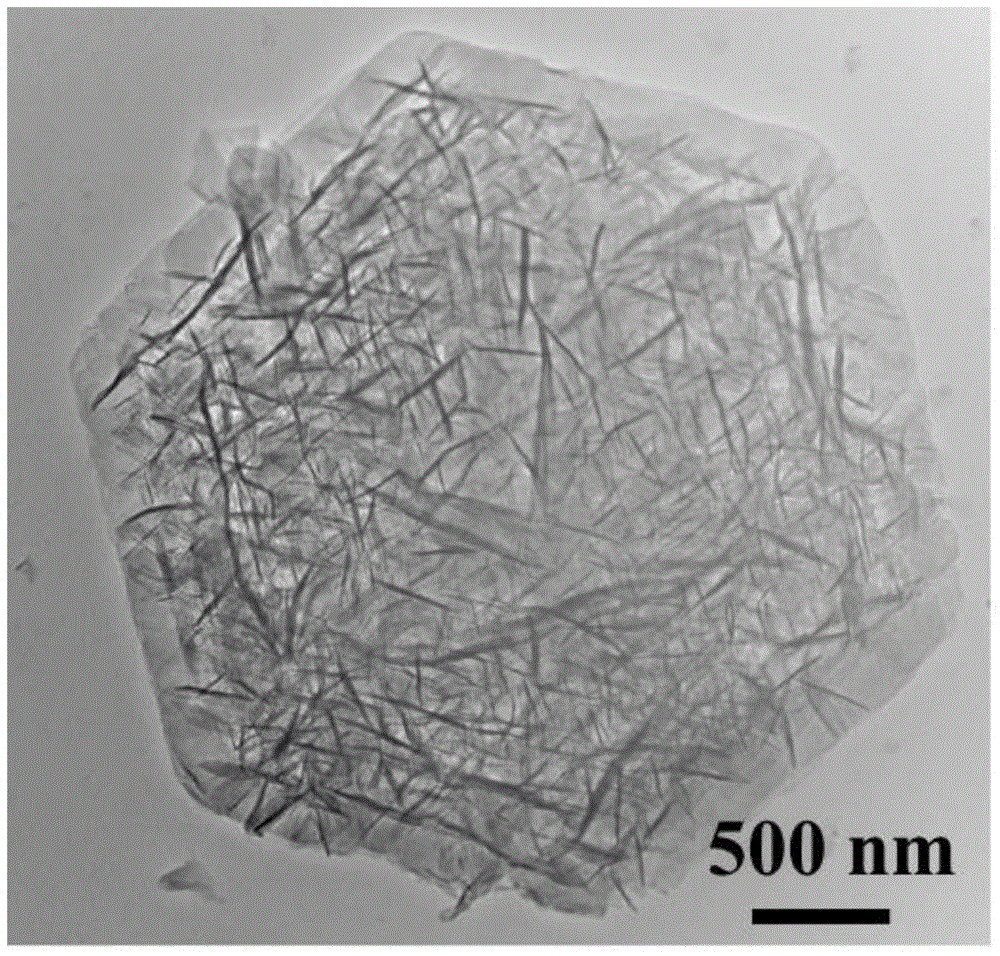

[0030] A. Weigh 2.56g Mg(NO 3 ) 2 ·6H 2 O, 1.88g Al(NO 3 ) 3 9H 2 O and 3.00g of urea were dissolved in 100ml of deionized water, the mixed solution was fully stirred, transferred to an autoclave, and crystallized at a constant temperature of 100°C for 24 hours, cooled to room temperature, followed by centrifugation, washing, and drying to obtain magnesium aluminum Hydrotalcite precursor;

[0031] B. Roast the hydrotalcite precursor at 400°C for 3 hours to obtain a magnesium-aluminum composite metal oxide. Take 0.20g of magnesium-aluminum composite metal oxide and place it in a 1.0M sodium hydroxide solution, stir vigorously for 2 hours, and centrifuge, After washing and drying, a multi-level structure hydrotalcite is obtained;

[0032] C. The polyethylene terephthalate substrate with a thickness of 193nm was ultrasonically cleaned with water, ethanol, and acetone for 10 minutes, then cleaned with deionized water, and dried at room temperature;

[0033] D. Adsorb the tr...

Embodiment 2

[0036] A. Weigh 2.56g Mg(NO 3 ) 2 ·6H 2 O, 1.25g Al(NO 3 ) 3 9H 2O and 2.0000g of urea were dissolved in 100ml of deionized water, the mixed solution was fully stirred, transferred to an autoclave, and crystallized at a constant temperature of 110°C for 36 hours, cooled to room temperature, followed by centrifugation, washing, and drying to obtain magnesium aluminum Hydrotalcite precursor;

[0037] B. Roast the hydrotalcite precursor at 450°C for 4 hours to obtain a magnesium-aluminum composite metal oxide. Take 0.4g of the composite metal oxide and place it in a 0.8M sodium hydroxide solution, stir vigorously for 3 hours, and centrifuge, wash, After drying, a multi-level structure hydrotalcite is obtained;

[0038] C. The high-density polyethylene substrate with a thickness of 25 μm was ultrasonically cleaned with water, ethanol, and acetone for 10 minutes, then cleaned with deionized water, and dried at room temperature;

[0039] D. Adsorb the treated high-density pol...

Embodiment 3

[0042] A. Weigh 2.56g Mg(NO 3 ) 2 ·6H 2 O, 0.94g Al(NO 3 ) 3 9H 2 O and 1.50g of urea were dissolved in 100ml of deionized water, the mixed solution was fully stirred, transferred to an autoclave, and crystallized at a constant temperature of 120°C for 48 hours, cooled to room temperature, followed by centrifugation, washing, and drying to obtain magnesium aluminum Hydrotalcite precursor;

[0043] B. Roast the hydrotalcite precursor at 500°C for 5 hours to obtain a composite metal oxide, take 0.6g of the composite metal oxide and place it in a 0.5M sodium hydroxide solution, stir vigorously for 4 hours, centrifuge, wash and dry Obtain multi-level structure hydrotalcite;

[0044] C. The polyurethane substrate with a thickness of 35 μm was ultrasonically cleaned with water, ethanol, and acetone for 10 minutes, then cleaned with deionized water, and dried at room temperature;

[0045] D. Adsorb the treated polyurethane substrate on a spin coating machine, and then alternat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxygen transmission rate | aaaaa | aaaaa |

| Oxygen transmission rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com