Waterproof and oxygen-insulating sealing film as well as preparation method and application thereof

A sealing film, waterproof barrier technology, applied in transportation and packaging, other chemical processes, chemical instruments and methods, etc., can solve the problems of difficult to obtain Graphene materials, high fluctuations, multiple wrinkles, etc., and achieve scientific and reasonable preparation methods and procedures. The effect of simple, excellent barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

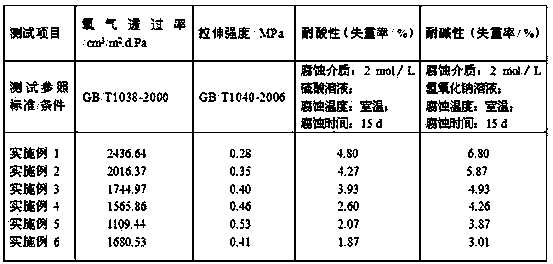

Embodiment 1

[0025] This example illustrates the composite material film composition, composite material film and preparation method thereof provided by the present invention.

[0026] Slowly pour 12 g of pre-dried EVA particles into a solution containing 120 ml of toluene (m EVA :V 甲苯 =1:10) and a round-bottomed flask with a magnetic rotor, after stabilization, the system was heated to 70 °C for 24 h to obtain a mixed paste liquid. Place the glass sheet on the film coating machine, and then apply the obtained pasty liquid on the glass sheet to control the thickness of the coating film to 0.07±0.01 mm. After the coating was completed, the glass sheet was left to air at room temperature for 24 h to fully evaporate the solvent to obtain a pure EVA material film.

Embodiment 2

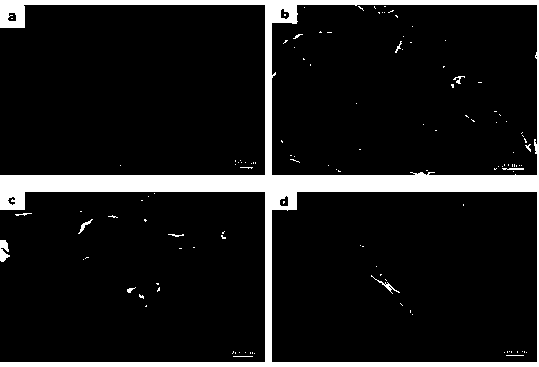

[0028] (1) Preparation of graphene oxide nanoribbons: weigh 180ml concentrated H 2 SO 4Slowly added to the round bottom flask, then 20ml 85.5 wt% H 3 PO 4 Add dropwise into concentrated sulfuric acid and stir evenly; after stabilization, add 1 g multi-walled carbon nanotubes and stir for 1 h, when the multi-walled carbon nanotubes are uniformly dispersed, mix 6 g KMnO 4 Slowly added to the above mixed solution for 0.5 h, then stirred at a constant speed for 0.5 h; then moved the above reaction system to an oil bath at 45°C, stirred and reacted for 1 d, and then slowly added the mixed system to a solution containing 500 ml deionized water in a large beaker, mix and stir for 1 h, when the temperature drops to room temperature, add 10 ml 30 wt% H 2 o 2 React for 2 h; then ultrasonically disperse the mixture in a 100 W ultrasonic cleaner for 0.5 h, add 100 ml of 38 wt% HCl and deionized water, filter and wash 4 times on a polytetrafluoroethylene filter membrane, and finally ...

Embodiment 3

[0034] Other condition parameters are the same as in Example 2, except that 0.024 g of functionalized graphene oxide nanobelts and 12 g of ethylene-vinyl acetate copolymer particles are added in step (3), and the prepared functionalized graphene oxide nanobelts / The ethylene-vinyl acetate copolymer composite film contains 0.2 wt% K-GONRs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com