Synthetic method of metal organic skeleton membrane

A technology of metal organic framework and synthesis method, applied in the field of synthesis of novel metal organic framework films, can solve the problems of difficulty in preparing continuous and dense metal organic framework films, easy detachment of crystal seeds, complex seed preparation and coating steps, etc. , to achieve good application value and prospects, wide versatility, enhanced hardness and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

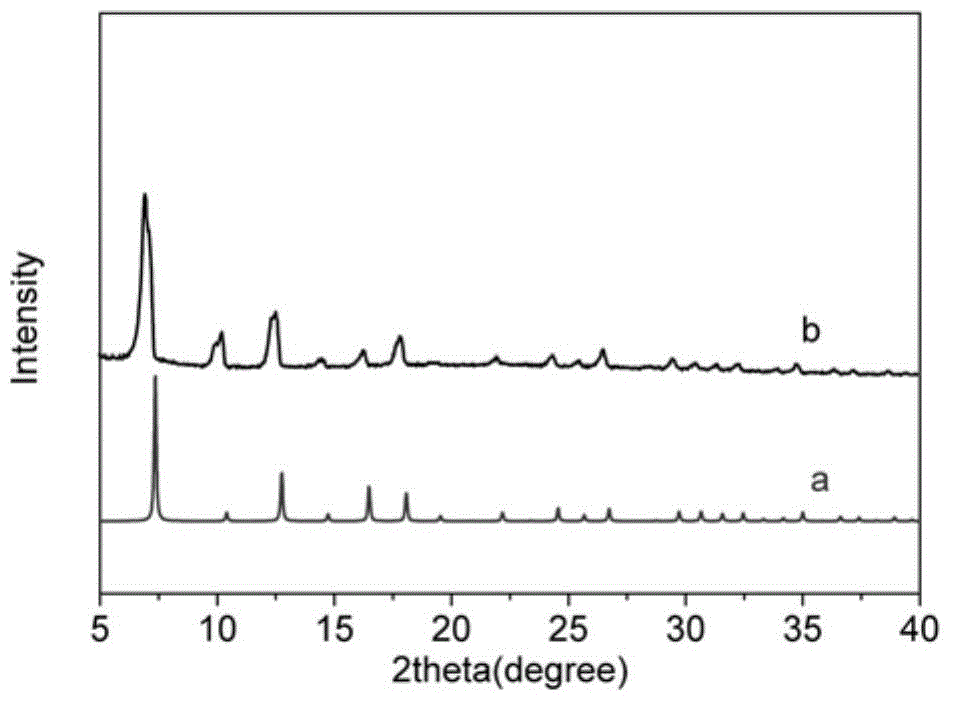

[0034] The substrate is polyethersulfone hollow fiber membrane, the metal gel is zinc gel, and the synthesized metal organic framework membrane is polyethersulfone / ZIF-8 membrane.

[0035] Preparation:

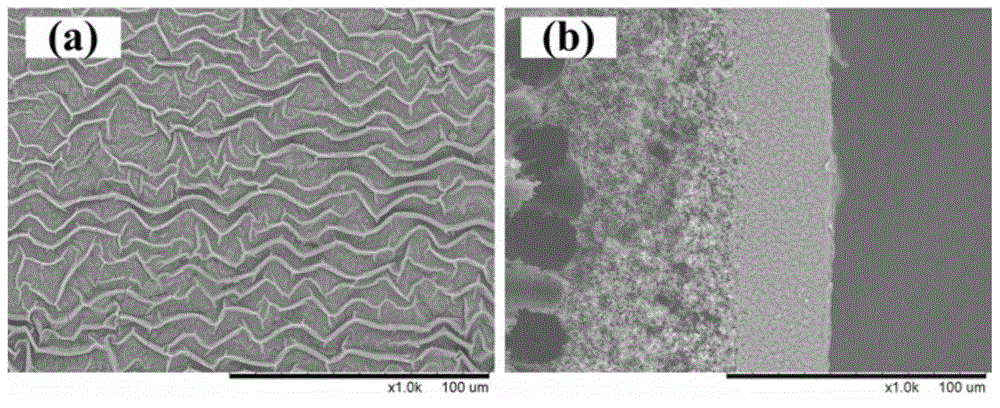

[0036] (1) Preparation of polyethersulfone hollow fiber membrane containing zinc gel: Zinc gel was prepared by sol-gel method, zinc acetate (5.2g, 0.0237mol) was added to ethanol (15mL) and heated at 60°C After stirring for 30 min, ethanolamine (1.5 mL) was added, and the reaction was stirred at 60°C for 10 min to obtain a transparent zinc sol without precipitation, which was left at room temperature for use. Put the polyethersulfone hollow fiber membrane into the zinc sol, ultrasonically vibrate for 10 minutes, take out the membrane containing the zinc sol, and dry it at 150° C. for 2 hours to obtain the polyethersulfone hollow fiber membrane containing the zinc gel ( figure 1 Its SEM picture), standby.

[0037] (2) Synthesis of polyethersulfone / ZIF-8 membrane: put the polyet...

Embodiment 2

[0040] The substrate is polyvinylidene fluoride hollow fiber membrane, the metal gel is zinc gel, and the synthesized metal organic framework membrane is polyvinylidene fluoride / ZIF-8 membrane.

[0041] Preparation:

[0042] (1) Preparation of polyvinylidene fluoride hollow fiber membrane containing zinc gel: Zinc gel was prepared by sol-gel method, and zinc acetate dihydrate (3.475g, 0.0158mol) was added to ethylene glycol ether (50mL) , stirred at 50°C for 30min, then added ammonia water (0.5mL), and stirred at 50°C for 10min to obtain a transparent zinc sol without precipitation, which was left at room temperature for use. Put the polyvinylidene fluoride hollow fiber membrane into the zinc sol, soak for 60 minutes, take out the membrane containing the zinc sol, and dry it at 60°C for 4 hours to obtain a polyvinylidene fluoride hollow fiber membrane containing zinc gel, which is ready for use.

[0043] (2) Synthesis of polyvinylidene fluoride / ZIF-8 membrane: put the polyvin...

Embodiment 3

[0045] The substrate is polysulfone flat membrane, the metal gel is copper gel, and the synthesized metal-organic framework membrane is polysulfone / CuBTC membrane.

[0046] Preparation:

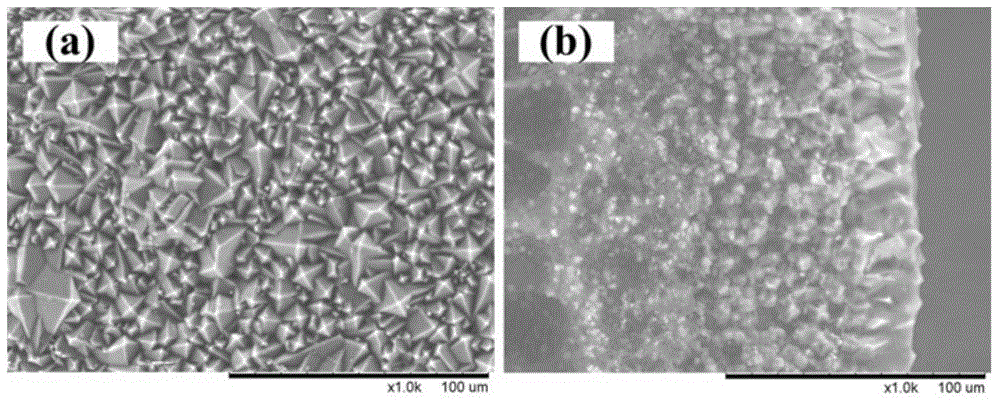

[0047] (1) Preparation of polysulfone flat membrane containing copper gel: Copper gel was prepared by sol-gel method, copper acetate (3.154g, 0.0158mol) was added to ethylene glycol ether (50mL) and heated at 50°C Stir at low temperature for 60 min, then add ethylenediamine (0.5 mL), and stir at 50°C for 10 min to obtain a blue copper sol without precipitation, which is left at room temperature for use. Put the polysulfone flat membrane into the copper sol, soak for 10 minutes, take out the membrane containing the copper sol, and dry it at 180°C for 2 hours to obtain a polysulfone flat membrane containing copper gel, which is ready for use.

[0048] (2) Synthesis of polysulfone / CuBTC membrane: put the polysulfone flat membrane containing copper gel obtained in step (1) into the prepared synt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com