Graphene oxide/metal organic frame composite film, preparation method and application thereof

A metal-organic framework and graphene technology, applied in chemical instruments and methods, separation methods, membrane technology, etc., can solve problems such as complex process, selection of layer thickness of membrane MOF, failure to fully utilize the structural characteristics of MOF, etc., to achieve improved separation Effects of performance, broad versatility, good application value and prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Modification of graphene oxide / metal gel: First, stir and ultrasonically disperse 0.1g graphene oxide in 100mL methanol solvent to prepare 1mg / mL GO dispersion; then add zinc acetate, stir and disperse at 50°C to prepare 10mg / mL zinc acetate solution; finally add an ethylenediamine stabilizer equal to the molar amount of the metal salt, and continue stirring for 0.5h to obtain a metal sol. Coating the prepared graphene oxide / metal sol on the surface of PES, the coating time is 2s, and after the coating is completed, treat at 100°C for 1 hour to obtain a graphene oxide / metal gel modified substrate;

[0027] (2) Preparing the precursor solution: add 0.1mol 2-methylimidazole and 0.025mol zinc acetate into 20mL methanol at a molar ratio of 4:1, then mix and stir evenly to obtain the MOF precursor solution;

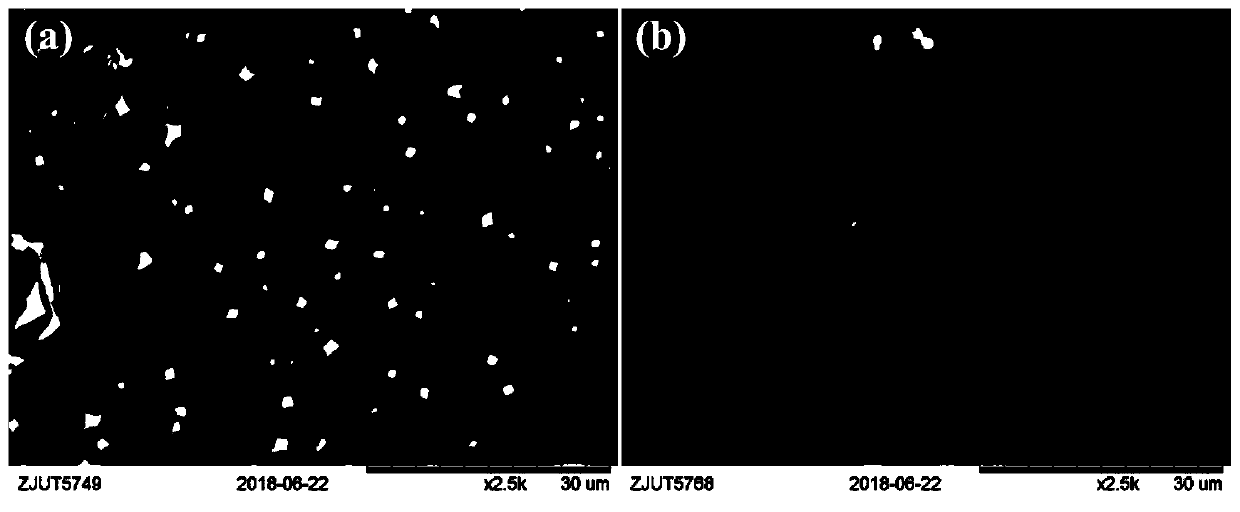

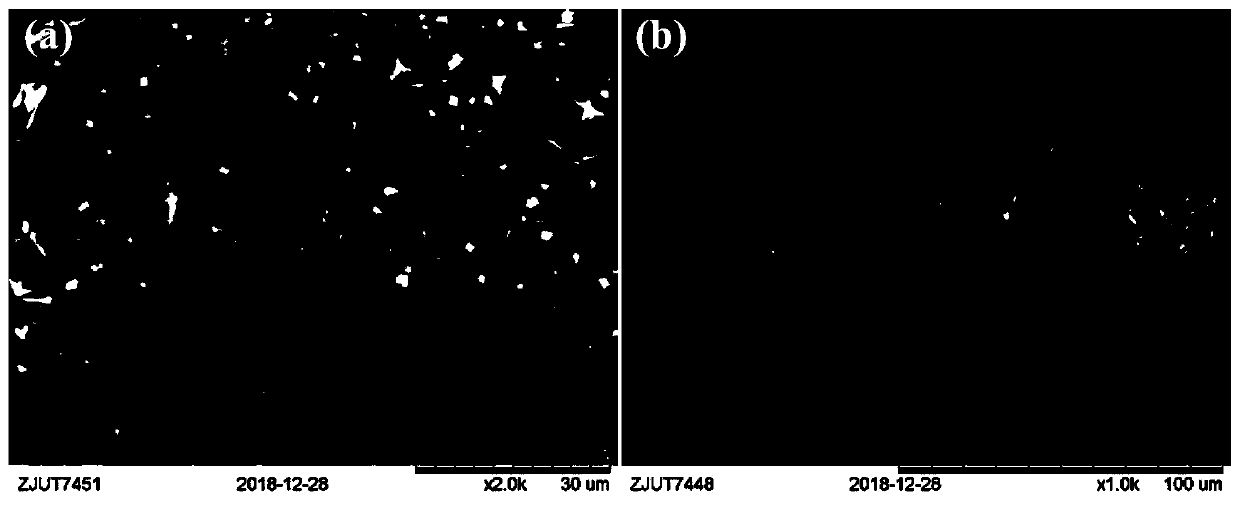

[0028] (3) Preparation of MOF composite membrane: The organic membrane modified by the composite gel is then immersed in the MOF precursor solution, and a dense MOF...

Embodiment 2

[0030] (1) Modification of graphene oxide / metal gel: First, stir and ultrasonically disperse 0.1g graphene oxide in 100mL methanol solvent to prepare 1mg / mL GO dispersion; then add copper acetate, stir and disperse at 50°C, Prepare a 10 mg / mL copper acetate solution; finally add an ethylenediamine stabilizer in an amount equal to the molar amount of the metal salt, and continue stirring for 0.5 h to obtain a metal sol. Coating the prepared graphene oxide / metal sol on the surface of PES, the coating time is 60s, after the coating is completed, treat at 100°C for 1 hour, and obtain the substrate modified by graphene oxide / metal gel;

[0031] (2) Preparing the precursor solution: add 0.1mol trimesic acid and 0.05mol copper acetate into 20mL methanol at a molar ratio of 2:1, then mix and stir evenly to obtain the MOF precursor solution;

[0032] (3) Preparation of MOF composite membrane: The organic membrane modified by the composite gel is then immersed in the MOF precursor solut...

Embodiment 3

[0034](1) Modification of graphene oxide / metal gel: First, stir and ultrasonically disperse 0.1g graphene oxide in 100mL methanol solvent to prepare 1mg / mL GO dispersion; then add copper acetate, stir and disperse at 50°C, Prepare a 10 mg / mL copper acetate solution; finally add an ethylenediamine stabilizer in an amount equal to the molar amount of the metal salt, and continue stirring for 0.5 h to obtain a metal sol. Coating the prepared graphene oxide / metal sol on the surface of PES, the coating time is 60s, after the coating is completed, treat at 100°C for 1 hour to obtain a graphene oxide / metal gel modified substrate;

[0035] (2) Prepare the precursor solution: add 0.1mol trimesic acid and 0.05mol copper acetate into 20mL ethanol at a molar ratio of 2:1, then mix and stir evenly to obtain the MOF precursor solution;

[0036] (3) Preparation of MOF composite membrane: The organic membrane modified by the composite gel is then immersed in the MOF precursor solution, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com