Polymer-based composite solid electrolyte film and preparation method thereof

A technology of solid electrolytes and polymers, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve problems such as low room temperature ionic conductivity, short-circuiting of positive and negative electrodes, shorten transmission path, control thickness, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

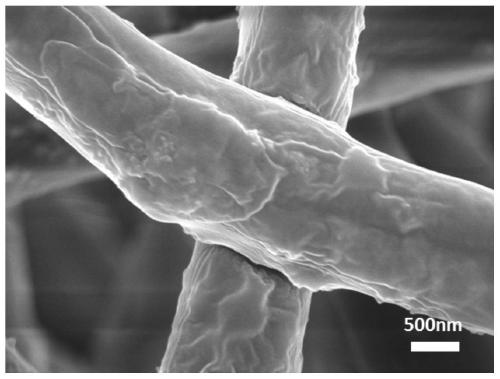

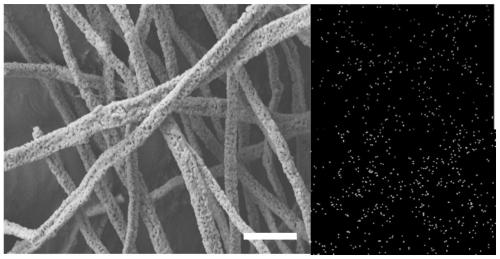

[0033] Weigh and take 1.045g of lithium nitrate, 5.47g of lanthanum nitrate hexahydrate dissolved in 5mlDMF, 2ml of acetic acid, and stir to a uniform and stable state, then add 10.419g tetrabutyl titanate and continue stirring to a uniform and stable state to obtain the LLTO stock solution, then Take out 3ml of the above prepared stock solution, add 0.5g Fe 3 o 4 Nanoparticles were pulverized in 3mlDMF with 300W power for 8h, then added 3mlLLTO stock solution taken out in the previous step, stirred for 30min evenly, added 0.5gPVP and stirred for 3h to form a stable sol, transferred the sol to a syringe for electrospinning, the electrospinning was performed at 1kV It is carried out under an electric field of / cm, and the sol is changed every 30min, and the morphology of the electrospun fiber is obtained by means of drum collection, as shown in the scanning electron microscope figure 1 , it can be seen that the diameter of the fiber before calcination is about 1 μm, and the Fe...

Embodiment 3

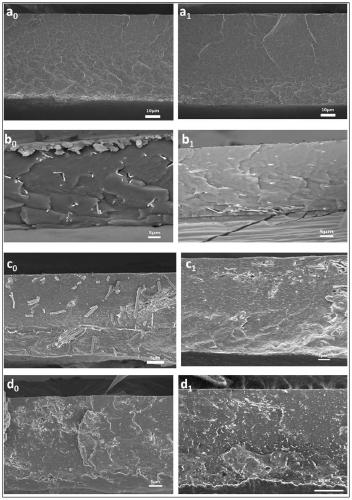

[0037] Take 0.05 g of the magnetic composite fiber in Example 1 and place it in 50 ml of ethanol, sonicate for 2 minutes at a power of 40 W, then centrifuge and dry to obtain a short magnetic composite fiber with a size of 1 μm-20 μm, measure 3 ml of DMF solvent, and add 0.014 g , composite fiber, 40W ultrasonic 2min, then add to the sol dissolved in PVDF and LiTFSI uniformly stirred in advance, stir for 5h to a uniform and stable state, then cast the mixture, dry at 80°C for 24h, part of the normal dry, the other A part is dried while introducing a parallel magnetic field with suitable magnetic field strength along the upper and lower sides of the electrolyte film to obtain a composite solid electrolyte film with a volume fraction of 0.5 vol% fibers randomly distributed and oriented and fibers present vertically oriented alignment. Such as image 3 middle b 0 , b 1 It can be seen that the fiber fillers in the composite electrolyte film oriented by the magnetic field obviou...

Embodiment 4

[0039] Take 0.05 g of the composite fiber in Example 1 and place it in 50 ml of ethanol, sonicate for 2 minutes at a power of 40 W, then centrifuge and dry to obtain a short magnetic composite fiber with a size of 1 μm-20 μm, measure 3 ml of DMF solvent, and add 0.028 g of Composite fiber, 40W ultrasonic for 2min, then added to the sol dissolved in PVDF and LiTFSI that was stirred evenly in advance, stirred for 5h to a uniform and stable state, then cast the mixture, dried at 80°C for 24h, part of it was normally dried, and the other part was in While drying, introducing a parallel magnetic field along the upper and lower sides of the electrolyte film with a suitable magnetic field strength can obtain a composite solid electrolyte film with a volume fraction of 1 vol% fibers randomly distributed and oriented and fibers showing vertical orientation. Such as image 3 middle c 0 、c 1 It can be seen that the fiber fillers in the composite electrolyte film oriented by the magneti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com