Lithium phosphate coated lithium iron phosphate electrode and preparation method thereof

A technology of coating lithium phosphate and lithium iron phosphate, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of low conductivity, complicated methods, and high cost, and achieve simple methods, high power, and reduced anisotropy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

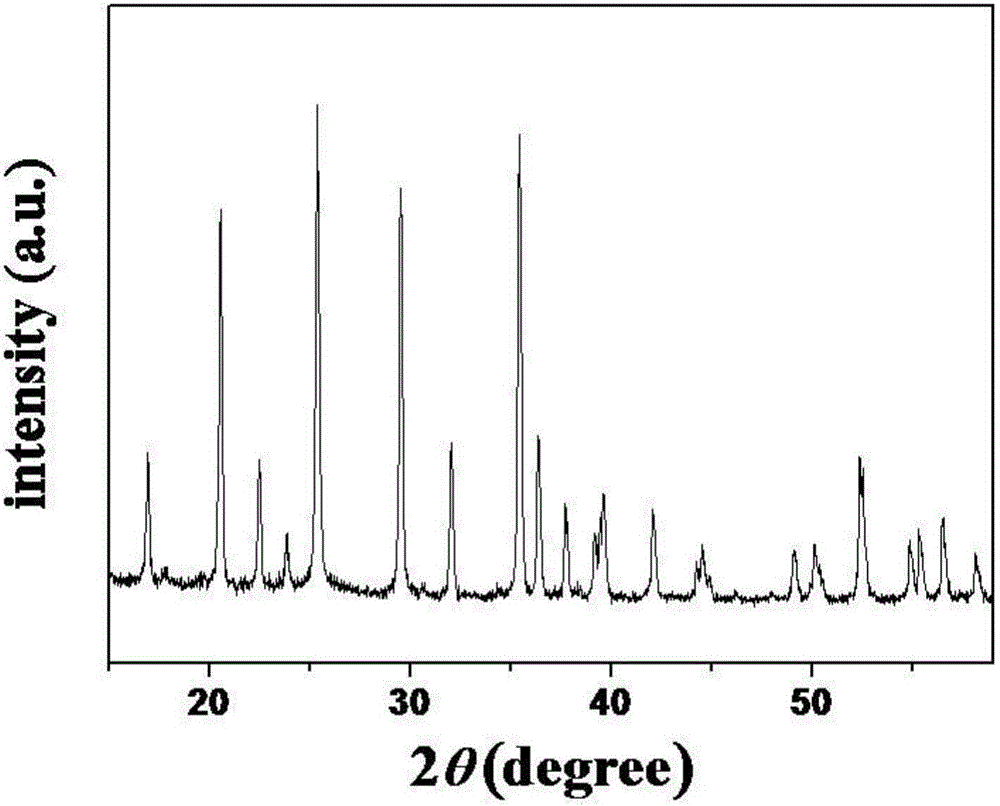

[0041] (1) Preparation of lithium phosphate target

[0042] Mix lithium phosphate powder with absolute ethanol, mill it in a ball mill at a speed of 400rpm for 5 hours, ball mill it into a slurry, place the slurry at 70°C for 48 hours in vacuum to obtain a powder, and make the powder into a 60mm-diameter ball by cold pressing The lithium phosphate target precursor was finally calcined in air at 600°C for 4h.

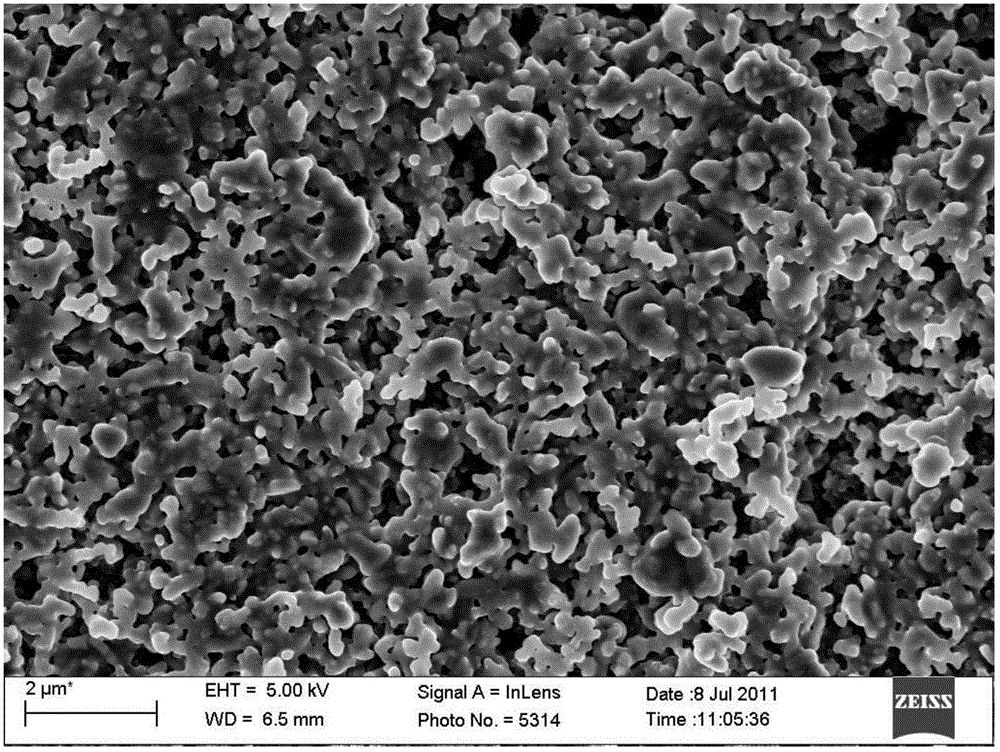

[0043] (2) Preparation of lithium iron phosphate electrode coated with lithium phosphate

[0044] Place the lithium iron phosphate electrode and lithium phosphate target as the substrate in the sputtering chamber of JGP450 ultra-high vacuum multifunctional magnetron sputtering equipment, the distance between the target and the substrate is 4cm, and the background pressure is 1.0 ×10 -5 Pa, sputtering by radio frequency magnetron sputtering, the power of radio frequency magnetron sputtering is 100W, the working pressure is 1.0Pa, the sputtering time is 5min, and the lit...

Embodiment 2

[0050] (1) Preparation of lithium phosphate target

[0051] Mix lithium phosphate powder with absolute ethanol, mill it in a ball mill at a speed of 400rpm for 5 hours, ball mill it into a slurry, place the slurry at 70°C for 48 hours in vacuum to obtain a powder, and make the powder into a 60mm-diameter ball by cold pressing The lithium phosphate target precursor was finally calcined in air at 600°C for 4h.

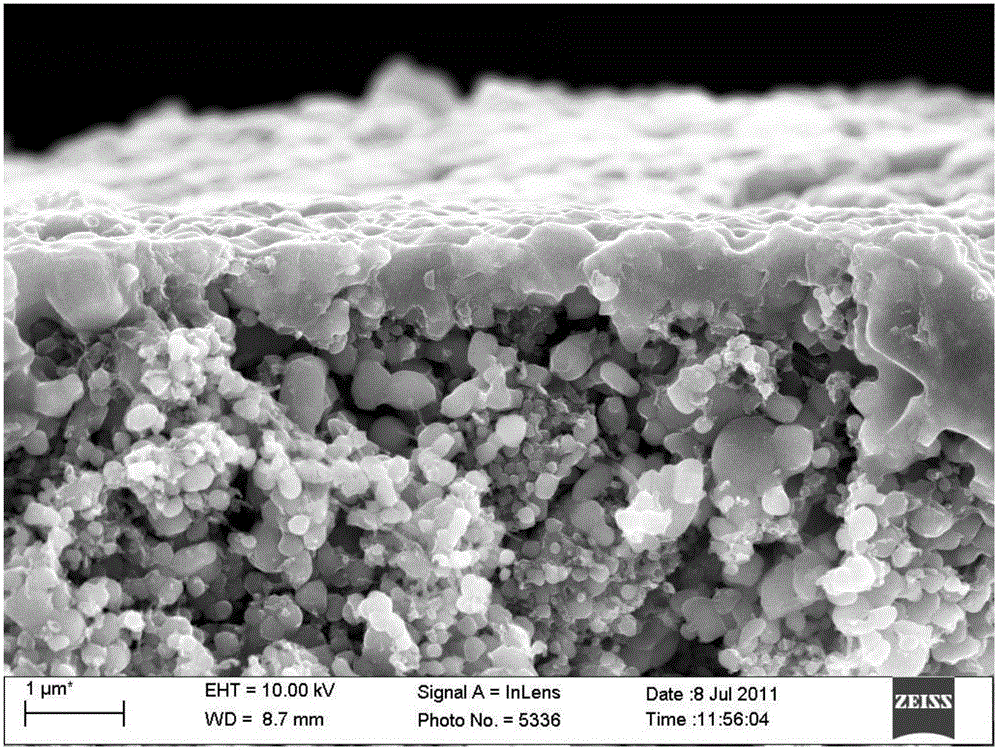

[0052] (2) Preparation of lithium iron phosphate electrode coated with lithium phosphate

[0053] Place the lithium iron phosphate electrode and lithium phosphate target as the substrate in the sputtering chamber of JGP450 ultra-high vacuum multifunctional magnetron sputtering equipment, the distance between the target and the substrate is 4cm, and the background pressure is 1.0 ×10 -5 Pa, sputtering by radio frequency magnetron sputtering, the power of radio frequency magnetron sputtering is 100W, the working pressure is 1.0Pa, the sputtering time is 20min, and the li...

Embodiment 3

[0059] (1) Preparation of lithium phosphate target

[0060] Mix lithium phosphate powder with absolute ethanol, mill it in a ball mill at a speed of 400rpm for 5 hours, ball mill it into a slurry, place the slurry at 70°C for 48 hours in vacuum to obtain a powder, and make the powder into a 60mm-diameter ball by cold pressing The lithium phosphate target precursor was finally calcined in air at 600°C for 4h.

[0061] (2) Preparation of lithium iron phosphate electrode coated with lithium phosphate

[0062] Place the lithium iron phosphate electrode and lithium phosphate target as the substrate in the sputtering chamber of JGP450 ultra-high vacuum multifunctional magnetron sputtering equipment, the distance between the target and the substrate is 4cm, and the background pressure is maintained at 1.0×10 -5 Pa, sputtering by radio frequency magnetron sputtering, the power of radio frequency magnetron sputtering is 100W, the working pressure is 1.0Pa, and the sputtering time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com