Composite negative electrode and preparation method thereof as well as electrochemical power source and application thereof

A negative electrode, electrochemical technology, applied in the field of composite negative electrode and its preparation, electrochemical power supply, can solve the problems of small electrode deposition thickness, complicated preparation process, low electrode preparation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

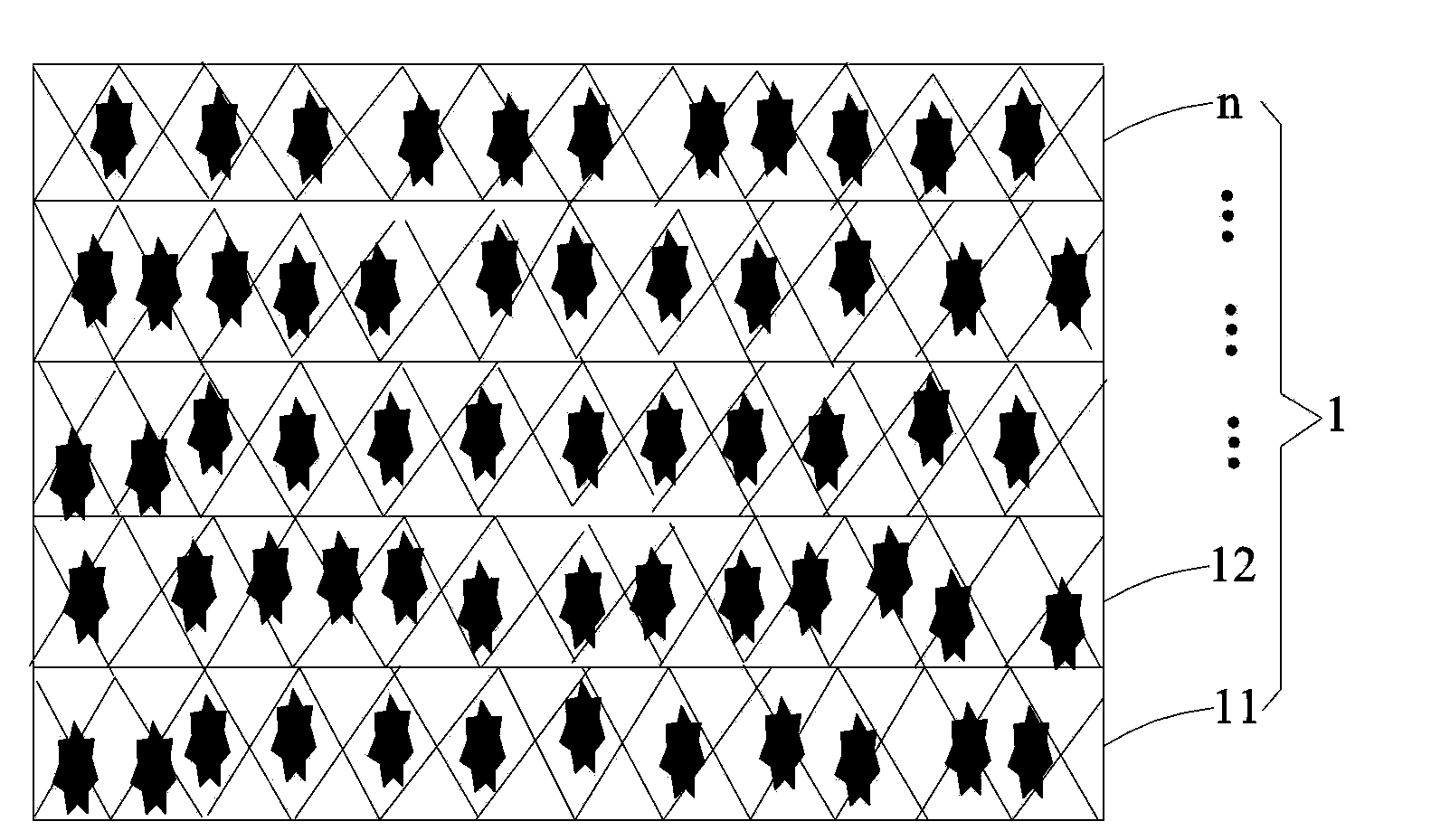

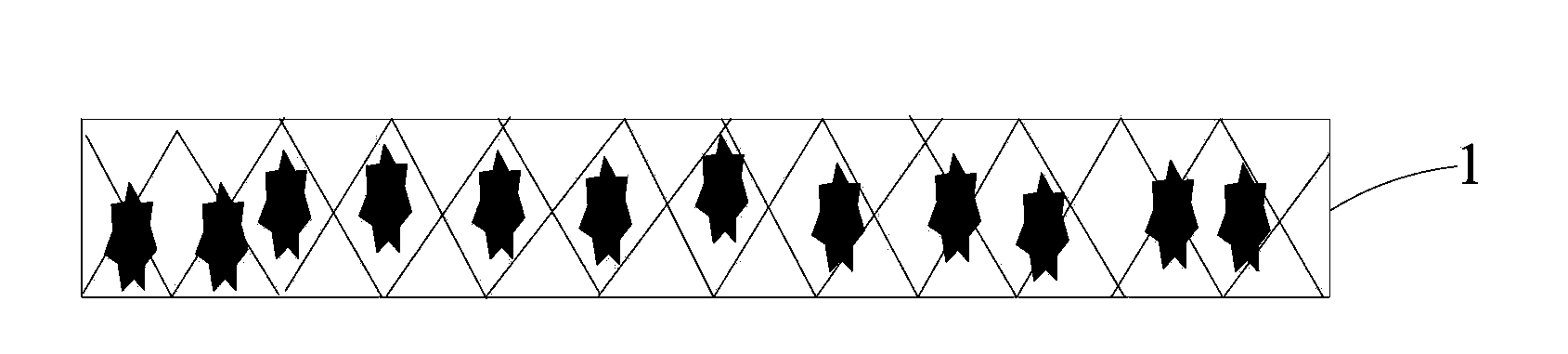

[0052] The example of the present invention also provides a method for preparing the above-mentioned composite negative electrode with a simple process. For the process flow of the composite negative electrode preparation method, please refer to Figure 5 , see also figure 1 and 2 , the preparation method of the composite negative electrode comprises the following steps:

[0053] S01. Prepare active material-containing slurry: disperse conductive agent, binder, and the above-mentioned active material capable of intercalating lithium ions in an aqueous or oily solvent, and prepare active material-containing slurry; wherein, the adhesive, The weight ratio of conductive agent to active material is (1~15):(0~15):100, and the content of active material in the slurry is 20~70%;

[0054] S02. Inject slurry: inject the slurry prepared in step S01 into the hole 2 of a porous current collector 1 and dry to obtain the composite negative electrode; or inject the slurry prepared in step...

Embodiment 1

[0068] A composite negative electrode and its preparation method:

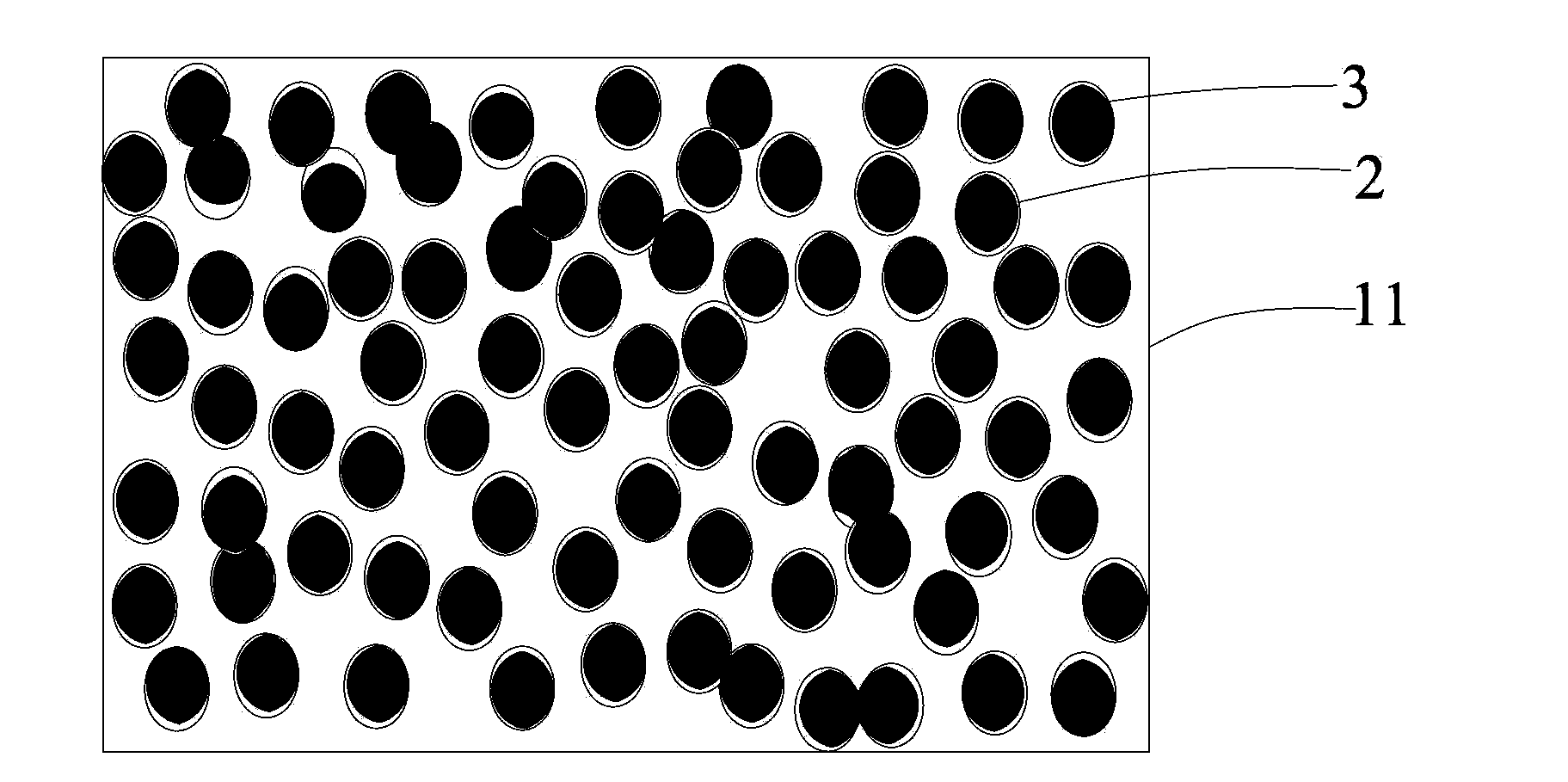

[0069] The composite negative electrode structure is as figure 2 , 3 As shown, it includes a nickel foam current collector 1 and its mesh 2 is filled with an active filler 3 . The thickness of the nickel foam 1 is 150 μm, and the active filler 3 contains a binder, a conductive agent and an active material capable of intercalating lithium ions in a weight ratio of 8:3:89. Among them, the binder is CMC, the conductive agent is SP, and the active material capable of intercalating lithium ions is Si, SiO with a weight ratio of 40:10:50. 2 and graphite nanopowder mixture.

[0070] The method of the composite negative electrode:

[0071] S11. Preparation of slurry containing active substances: Add active substance powder (active substance is not a simple powder mixture, but sintered by a certain process, and it is already a uniformly dispersed compound) into pure water, and disperse by ultrasonic waves Uniform...

Embodiment 2

[0075] A composite negative electrode and its preparation method:

[0076] The composite negative electrode structure is as figure 2 , 4 As shown, it includes two layers of copper mesh collectors 11 and 12 that are laminated and combined into one, and active fillers 3 filled in the holes 2 of the copper mesh collectors 11 and 12 . The thickness of the copper mesh current collectors 11 and 12 is 50 μm, and the active filler 3 contains a binder, a conductive agent and an active material capable of intercalating lithium ions in a weight ratio of 6:3:91. Among them, the binder is PVDF, the conductive agent is VGCF, and the active material capable of intercalating lithium ions is nano-scale stannous oxide powder.

[0077] The method of the composite negative electrode:

[0078] S21. Preparation of slurry containing active substances: Add PVDF to NMP solvent to prepare a gel solution, then add the mixture of nano-stannous oxide powder and VGCF conductive agent mixed uniformly in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com