Film for producing composite paper-like film and paper-like film and method for producing the same

A film and paper film technology, which is applied in the manufacture of composite paper-like film films and composite paper-like films and their production fields, can solve the problems of film tensile strength not reaching the highest value and high manufacturing cost, and achieve excellent printing effects and products The effect of low cost and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

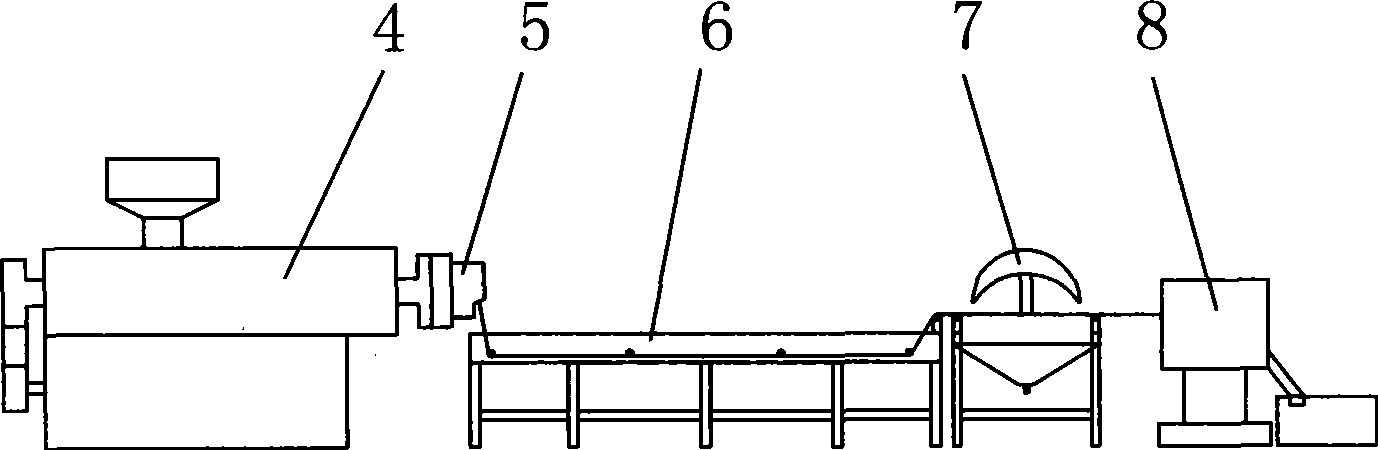

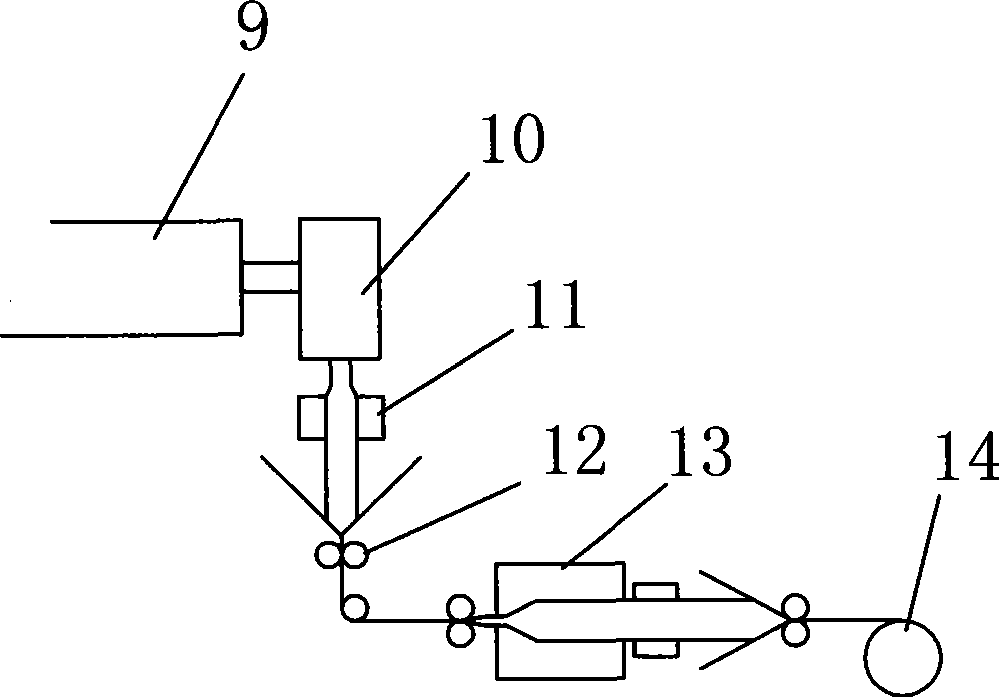

Method used

Image

Examples

Embodiment Construction

[0029] The film of the present invention is made up of following composition: resin, filler and auxiliary agent, the proportioning of parts by weight of resin, filler and auxiliary agent is:

[0030] Resin:filler:auxiliary agent=100:50~200:0.1~5.

[0031] The resin is polyethylene or polypropylene or polyvinyl chloride or polyvinylidene chloride or polyvinyl alcohol or nylon.

[0032] The filler is calcium carbonate, or at least one of calcium carbonate and kaolin, mica powder, silicon dioxide and talcum powder.

[0033] Auxiliaries are coupling agents, stabilizers, plasticizers and lubricants, or coupling agents, stabilizers, plasticizers and lubricants and toughening agents, antioxidants, antistatic agents, ultraviolet absorbers at least one.

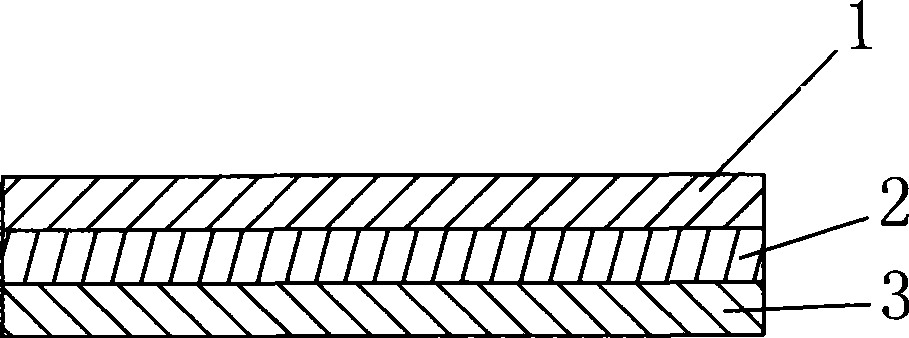

[0034] The cross-sectional structure of the composite paper-like film of the present invention is layered, and consists of an upper film 1, a lower film 3 and an adhesive layer 2 between the upper film 1 and the lower film 3. The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com