Method for preparing metal organic framework film

A metal-organic framework and metal technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as weak binding force and difficult film formation, and achieve the effect of easy operation and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

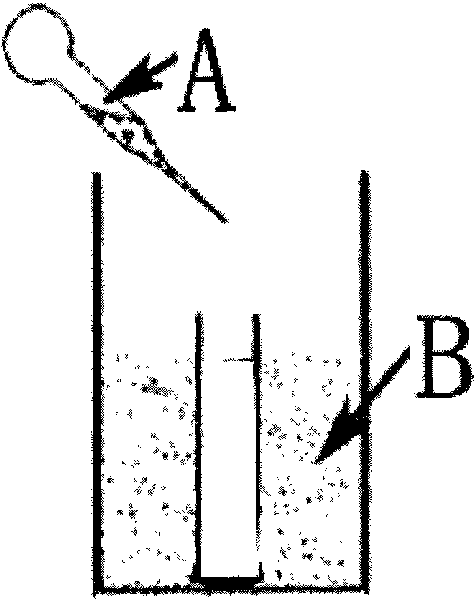

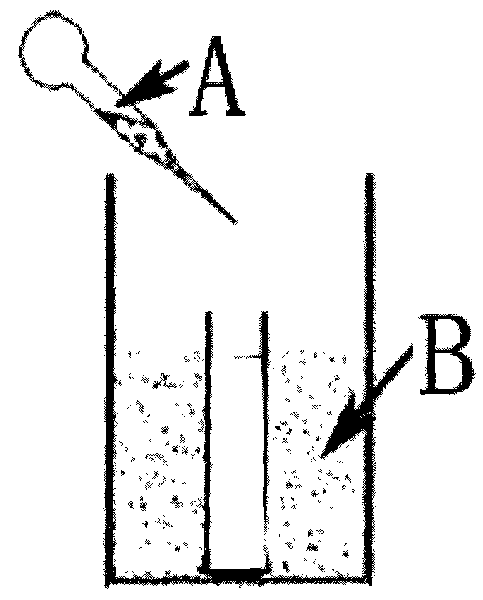

[0017] Example 1 Synthesis of Cu3(BTC)2 film

[0018] In a 100ml beaker, 3.75g Cu(NO 3 ) 2 Dissolve it in 12 g of water to form a solution A. In another 100 ml beaker, dissolve 0.08 g of 1,3,5-tribenzenetricarboxylate (BTC) BTC in 24 g of ethanol to form a solution B. Take the pretreated carrier, seal the bottom end of the tube with a PTFE head, then pour the A solution into the tube, and then seal the other end with a PTFE head. After sealing, put the tube into Into the reaction kettle, inject solution B, then seal the kettle and place it at 120°C for crystallization synthesis for 12 hours. The prepared Cu3(BTC)2 membrane is rinsed with deionized water / ethanol and dried in a vacuum oven at 40°C spare. The entire synthesis process must be repeated twice until the synthesized membrane is dense and continuous.

[0019] Single gas test: install the Cu3(BTC)2 membrane prepared above into the membrane separator. At room temperature, the pressure difference between the two ends of the ...

Embodiment 2

[0020] Example 2 Synthesis of MOF-5 film:

[0021] Put 0.399g Zn(NO 3 ) 2 Fully dissolve in 2.846g dimethylformamide (N,N'-dimethylformamide, DMF) to form a solution A, in another 100ml beaker, dissolve 0.0502g phthalic acid (1,4-benzenedicarboxylate, BDC) in 12.33g DMF Form B solution. (Take the pretreated carrier, seal the bottom end of the tube with a Teflon cap, then pour the A solution into the tube, and then seal the other end with a Teflon cap. After sealing, put the tube into Into the reaction kettle, inject solution B, then seal the kettle and place it at a temperature of 100°C for crystallization synthesis for 12 hours. The prepared MOF-5 membrane is rinsed with DMF and dried in a vacuum oven at 40°C for use. The entire synthesis process The synthesis should be repeated twice until the synthesized film is dense and continuous.

[0022] Single gas test: Install the prepared MOF-5 membrane above into the membrane separator. At room temperature, the pressure difference bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com