Pressure sensitive adhesive for transporting flexible substrate

A technology for flexible substrates and adhesives, applied in the direction of film/sheet adhesives, adhesives, passive exercise equipment, etc., can solve the problem of reduced adhesive bonding strength, difficult to transfer substrates, and inability to adhesive Eliminate the problems of reusing the support, etc., and achieve the effect of tight adhesion and tight transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0067] Hereinafter, a method of transferring a flexible substrate using the above adhesive composition will be described in detail with reference to the accompanying drawings.

[0068] First, a method of transferring a flexible substrate according to a first embodiment of the present invention will be described in detail.

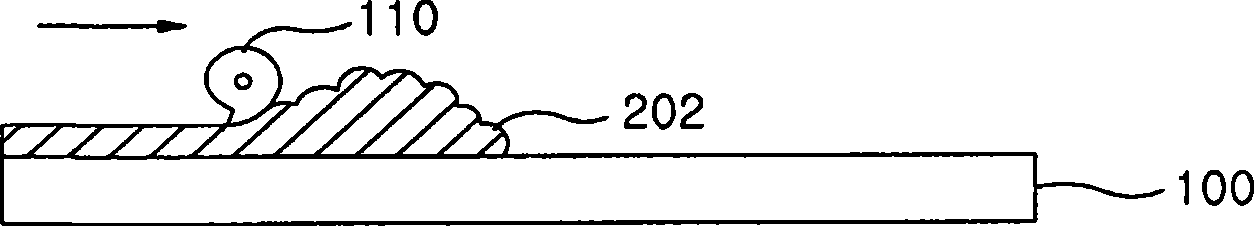

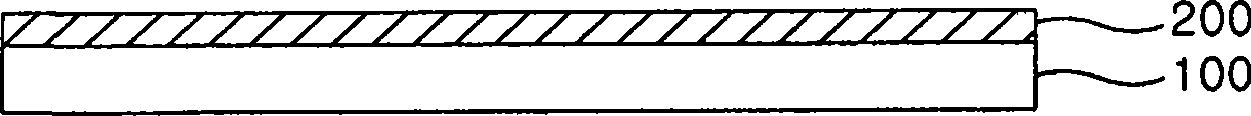

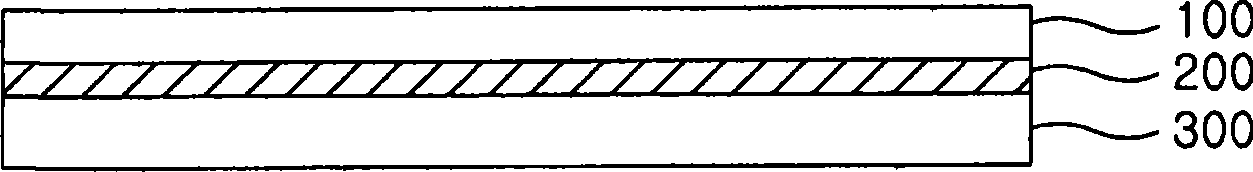

[0069] Figure 1~4 is a sectional view showing a method of transferring a flexible substrate according to a first embodiment of the present invention.

[0070] refer to figure 1 , place a predetermined amount of the adhesive composition 202 on the flexible substrate 100 , and then use the coating machine 110 to coat the adhesive composition 202 on the flexible substrate 100 at a constant speed. A coater known in the related art such as a wire bar coater, a roll coater, a reverse coater, a gravure coater, or an air knife coater can be used as the coater 110 described above.

[0071] In addition, such as polyester, polytetrafluoroethylene, polyimide, polyp...

Embodiment

[0098]

[0099] An alkenyl-containing polydimethylsiloxane, wherein a vinyl block is used at the end of the molecular chain of the polydimethylsiloxane, and the polydimethylsiloxane contains 0.15 mol % of methylethylene base siloxane units, and the polydimethylsiloxane is dissolved in toluene to have a viscosity of 2200 mPas when it has a solids content of 30%; 60% contains Me 3 SiO 1 / 2 Cell and SiO 2 Unit (Me 3 SiO 1 / 2 Unit / SiO 2 Units = 0.85) in toluene solution of polyorganosiloxane; and Me used as crosslinking agent 3 SiO-[MeHSiO] 40 SiMe 3 mix. Next, toluene, gamma-glycidoxypropyltrimethoxysilane used as a silane coupling agent and chloroplatinic acid based on platinum group elements were added to 100 parts by weight of the composition to finally prepare a solid content of 30% silicone adhesive composition. In Table 1 the components and contents of the prepared compositions are given.

[0100] The prepared composition was diluted to an appropriate concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com