Aqueous epoxy coating for terraces, and preparation method thereof

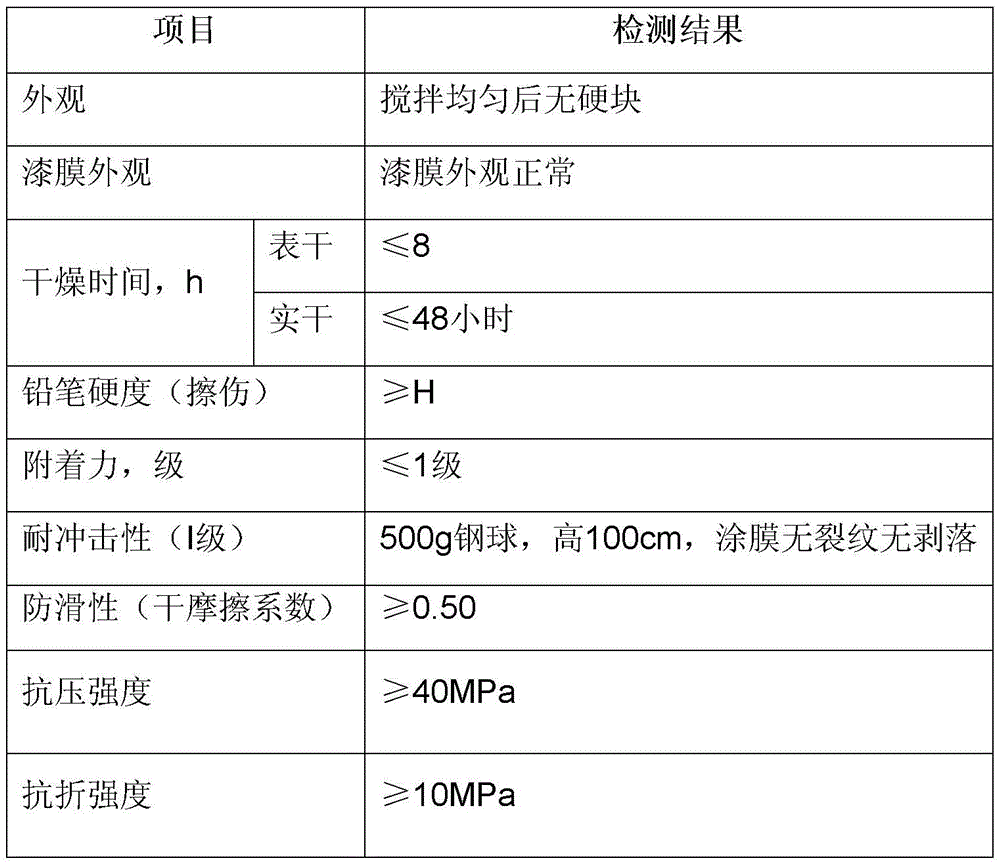

An epoxy floor and water-based epoxy technology, which is applied in the field of floor coatings, can solve the problems of crack resistance, flexural strength and compressive strength of the repair position, and short service life, so as to improve the stability and Appearance effect, reduced cracking probability, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0021] (1) The water-based epoxy curing agent preferably adopts a water-dilutable amine curing agent that does not contain surfactants, for example: the amine curing agent that can adopt the model produced by Air Chemical Company is AN721; this water-based epoxy Oxygen curing agent has good compatibility with epoxy resin, and can be cured at room temperature or at high temperature, and the coating formed by this water-based epoxy curing agent and epoxy resin after curing has high hardness. , Excellent adhesion, wear resistance, scrub resistance, chemical corrosion resistance, mildew resistance, etc.

[0022] (2) The water-based epoxy floor coating uses high-grade cement, coarse quartz sand and fine quartz sand mixed in a specific ratio, and both the coarse quartz sand and the fine quartz sand are made of pure natural high-strength quartz sand, so the water-based epoxy floor coating The final coating formed by epoxy floor coatings has good overall strength.

[0023] (3) The de...

Embodiment 1

[0034] A kind of this waterborne epoxy floor paint, adopts following preparation method to make:

[0035] Step A1. According to the ratio of high grade cement: coarse quartz sand: fine quartz sand: water reducer: defoamer: cellulose = 30:20:50:0.1~0.2:0.1~0.3:0.1~0.3 in parts by weight, Weigh high grade cement, coarse quartz sand, fine quartz sand, water reducer, defoamer and cellulose respectively, and mix high grade cement, coarse quartz sand, fine quartz sand, water reducer, defoamer and cellulose Put them into a dry powder mixing tank and mix evenly to obtain the third component; wherein, the high-grade cement is No. 325 cement, and the coarse quartz sand is quartz sand with a particle size between 40 and 80 meshes. The fine quartz sand is quartz sand with a particle size of 80-120 mesh.

[0036] Step B1. According to the ratio of water-based epoxy curing agent: bisphenol A liquid epoxy resin: the third component = 1.2:1:7 in parts by weight, respectively weigh water-base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com