Low dielectric coefficient polyimide/oligomeric silsesquioxane nano hybrid film and preparation thereof

A technology of polysilsesquioxane and low dielectric constant, which is applied in the field of polymer dielectric materials, can solve problems such as thermal/chemical stability and dielectric performance conflicts, and achieve improved compatibility, excellent comprehensive performance, Effect of low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

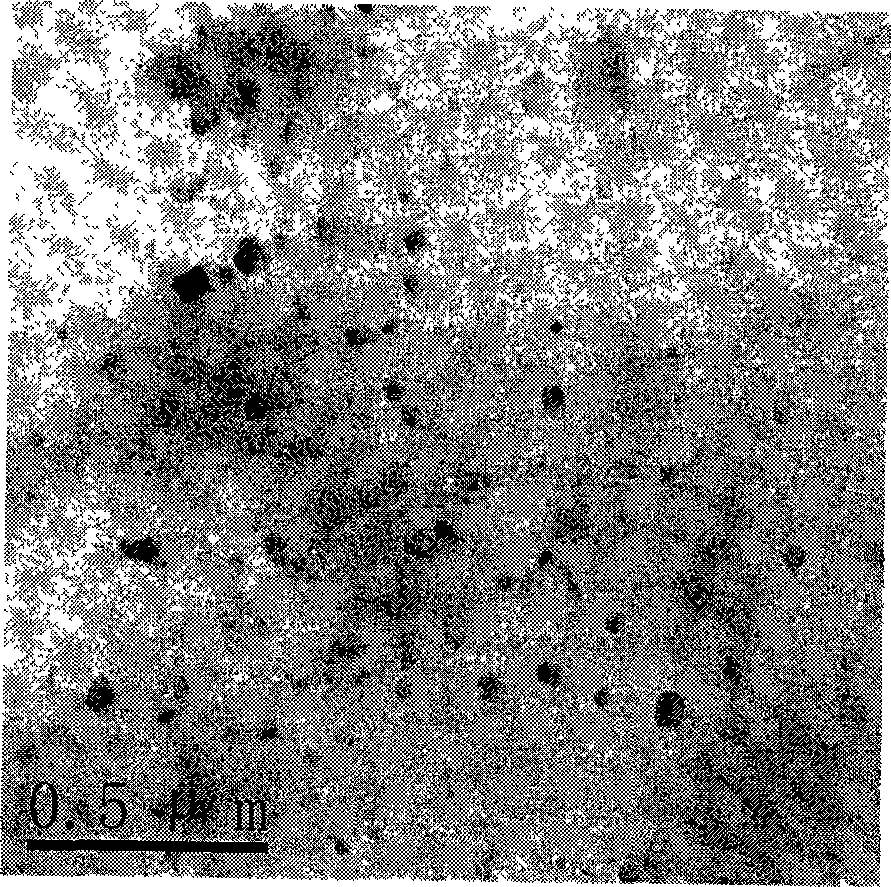

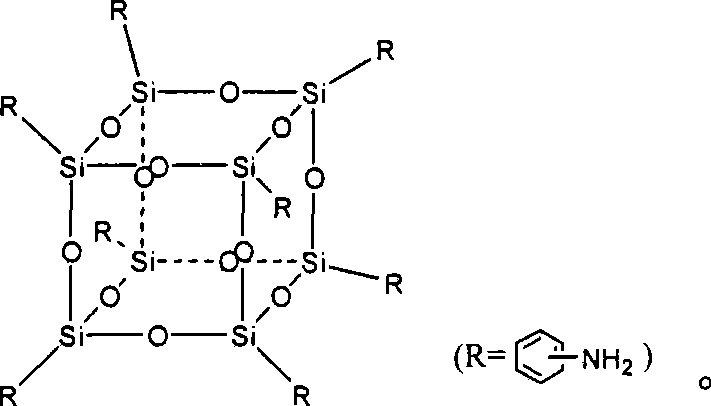

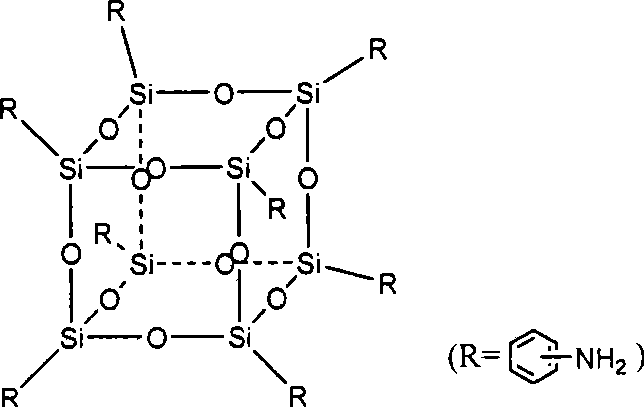

[0042] Dissolve 1.3g of octaaminophenyl silsesquioxane (referred to as OAPS) in 15ml of N-methylpyrrolidone (referred to as NMP), after fully dissolving, slowly drop into 10ml containing 3,3',4,4'- NMP solution of 2.9 g of benzophenone tetraacid dianhydride (BTDA); after the dropwise addition, react at 30°C for 1 hour under nitrogen atmosphere to obtain silsesquioxane with acid anhydride functional groups;

[0043] Dissolve 2.0g 4,4'-diaminodiphenyl ether (ODA) monomer in 30ml of NMP, after fully dissolving, add 1.0ml of the above-mentioned silsesquioxane solution with acid anhydride functional group dropwise; then add BTDA 3.1g, the feeding time was controlled at 60 minutes, after the feeding was completed, the reaction was carried out at 20°C for 20 hours under a nitrogen atmosphere to obtain a uniform polyamic acid solution with a solid content of 0.18g / ml;

[0044] The above polyamic acid solution was formed into a film on a glass plate, and the imidization treatment was c...

Embodiment 2

[0046] Dissolve 1.3g of octaaminophenyl silsesquioxane (referred to as OAPS) in 15ml of N,N-dimethylacetamide (referred to as DMAc), after fully dissolving, slowly drop into 10ml containing 3,3',4 , a DMAc solution of 2.9 g of 4'-benzophenone tetracarboxylic dianhydride (BTDA); after the dropwise addition, the reaction was carried out at 20°C for 1.5 hours under a nitrogen atmosphere to obtain a silsesquioxane with acid anhydride functional groups;

[0047] Dissolve 2.0g of 4,4'-diaminodiphenyl ether (ODA) monomer in 30ml of DMAc, after fully dissolving, add 5.2ml of the above-mentioned silsesquioxane solution with acid anhydride functional group dropwise; then add BTDA2.6g, the feeding time was controlled at 50 minutes, after the feeding was completed, the reaction was carried out at 15°C for 24 hours under a nitrogen atmosphere to obtain a uniform polyamic acid solution with a solid content of 0.18g / ml;

[0048] The above polyamic acid solution was formed into a film on a gl...

Embodiment 3

[0050] Dissolve 1.3g of octaaminophenyl silsesquioxane (referred to as OAPS) in 15ml of N,N-dimethylacetamide (referred to as DMAc), after fully dissolving, slowly drop into 10ml containing 3,3',4 , a DMAc solution of 2.9 g of 4'-benzophenone tetraacid dianhydride (BTDA); after the dropwise addition, the reaction was carried out at 15°C for 2.5 hours under a nitrogen atmosphere to obtain a silsesquioxane with an acid anhydride functional group;

[0051] Dissolve 2.0g 4,4'-diaminodiphenyl ether (ODA) monomer in 30ml of DMAc, after fully dissolving, add 15.7ml of the above silsesquioxane solution with acid anhydride functional group dropwise; then add BTDA 1.47g, the feeding time was controlled at 30 minutes, and after the feeding was completed, the reaction was carried out at 25° C. for 16 hours under a nitrogen atmosphere to obtain a uniform polyamic acid solution with a solid content of 0.20 g / ml;

[0052] The above polyamic acid solution was formed into a film on a glass pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com