Hydrophilic soil release finish method for fabrics

An easy decontamination and hydrophilic technology, applied in fiber treatment, textiles and papermaking, fiber types, etc., can solve the problems of fluorine pollution, high cost, non-environmental-friendly additives, etc., and achieve simple treatment process, low cost, The effect of excellent hydrophilicity and easy decontamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1. Fabric: 150D / 72F DTY polyester jersey

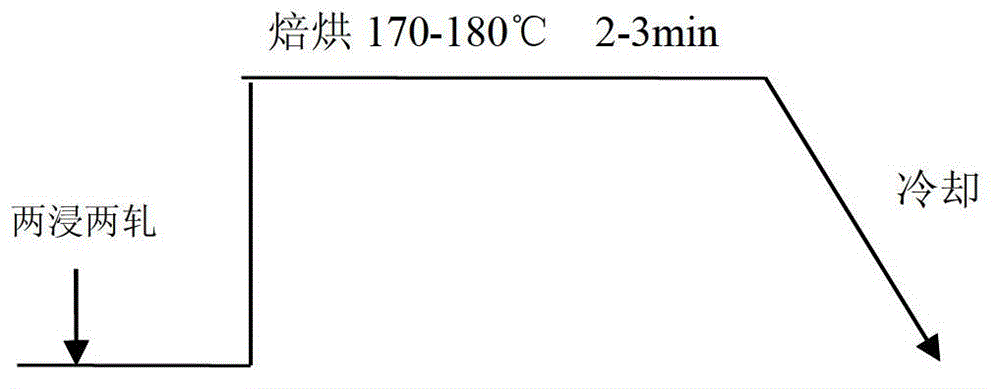

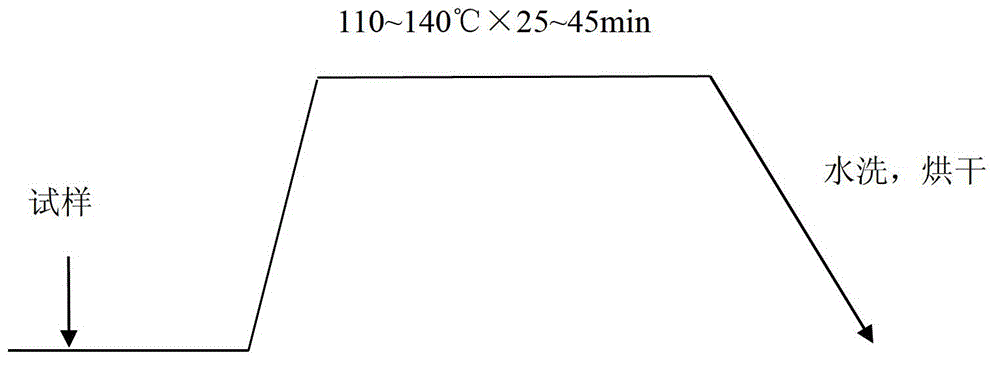

[0014] 2. Hydrophilic and easy decontamination finishing process

[0015] Dipping method: hydrophilic and easy decontamination finishing agent SR 3% (owf.)

[0016] Dipping temperature 140℃

[0017] Dipping time 25min

[0018] 3. Hydrophilic and easy decontamination performance test method:

[0019] 1. Hydrophilicity test: capillary effect

[0020] Hang the sample (20cm×2.5cm) vertically, immerse the lower end (0.5cm) of the sample in distilled water, and test the height reached by the liquid after 30 minutes.

[0021] 2. Ease of decontamination test: Ease of decontamination test standard refers to AATCC 130-2000 method

[0022] Use a medical dropper to drop 5 drops (about 0.2mL) of engine oil in the middle of the test cloth, cover the top and bottom of the sample with filter paper, press it with a 5kg weight at room temperature for 60s, remove the weight, remove the filter paper, and take out The sample w...

Embodiment 2

[0027] 1. Fabric: 100D / 72F FDY polyester jersey

[0028] 2. Hydrophilic and easy decontamination finishing process

[0029] Dipping method: hydrophilic and easy-to-decontaminate finishing agent SR 4% (owf.)

[0030] Dipping temperature 120℃

[0031] Dipping time 35min

[0032] 3. Hydrophilic and easy decontamination performance test method: same as Example 1

[0033] 4. Test results:

[0034] The capillary effect of the fabric in this case is 20.0cm (the capillary effect without hydrophilic and easy-to-decontamination finishing is 4.1cm), and the capillary effect after washing 50 times is 19.3cm.

[0035] Easy decontamination level: 2 as original, 4.5 for the fabric in this case, and 4.5 after 50 washes.

Embodiment 3

[0037] 1. Fabric: nylon / spandex (97 / 3) blended jersey

[0038] 2. Hydrophilic and easy decontamination finishing process

[0039] Immersion method: hydrophilic and easy decontamination finishing agent SR 5% (owf.)

[0040] Dipping temperature 110℃

[0041] Dipping time 45min

[0042] 3. Hydrophilic and easy decontamination performance test method: the same as in Example 1.

[0043] 4. Test results:

[0044] The capillary effect of the fabric in this case is 10.4cm (the capillary effect without hydrophilic and easy-to-decontaminate finishing is 4.3cm), and the capillary effect after washing 50 times is 9.9cm. (This gross difference from the previous two cases is due to the difference in fabric materials. The effect of hydrophilic and easy-to-decontamination finishing is reflected by the comparison of the gross effect of the fabric before and after finishing. In this case, the treated fabric is better than the untreated fabric. The wool effect of the fabric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com