Hydrophilic modification method for polyester fibers with bromoethane and PVA

A polyester fiber and hydrophilic modification technology, which is applied in fiber treatment, fiber type, textiles and papermaking, etc., can solve the problems of unfavorable industrial production and complicated operation, and achieve the benefits of industrial promotion, good water and sweat absorption, and subsequent operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

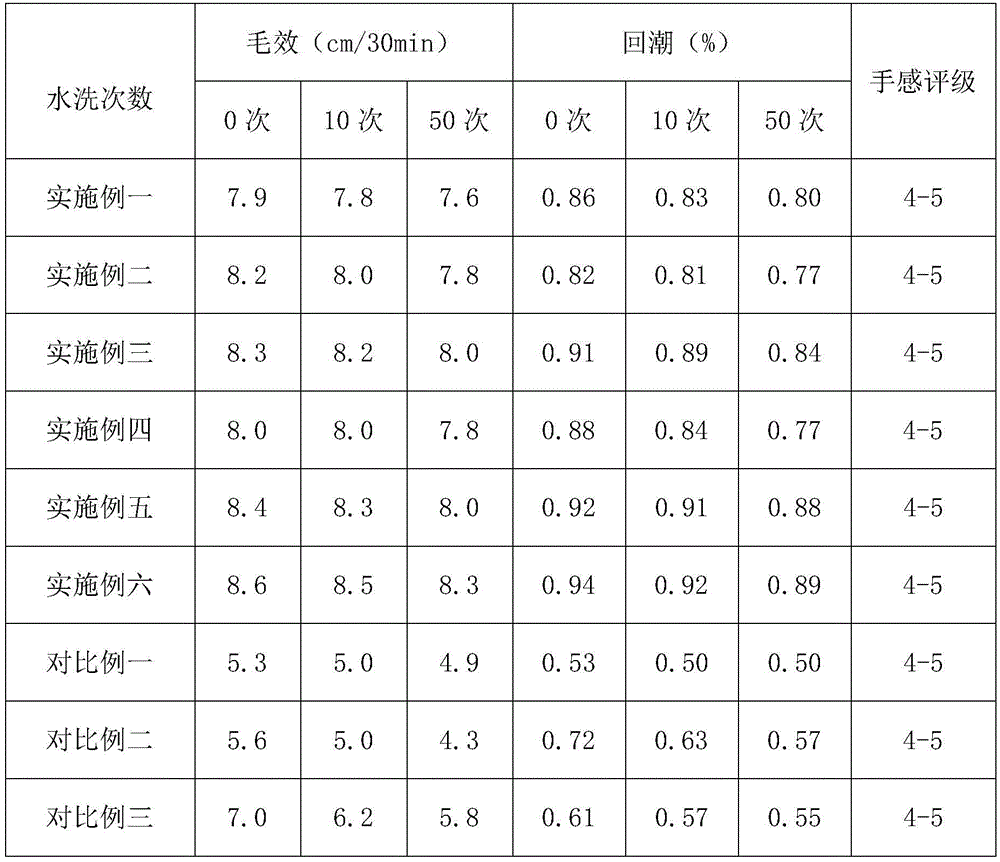

Examples

Embodiment 1

[0028] A kind of bromoethane and PVA to the hydrophilic modification method of polyester fiber:

[0029] Add a sodium hydroxide solution with a mass fraction of 6% to the polyester fiber, stir and pretreat it at 60°C for 2 hours, the mechanical stirring speed is 100 rpm, and the solid-to-liquid ratio of the polyester fiber to the sodium hydroxide solution is 1: 30. Rinse with water after pretreatment, and dry at low temperature;

[0030] Add ethyl bromide solution to the polyester fiber after low-temperature drying, add pyridine p-toluenesulfonate solid of 0.01% of the dry weight of the polyester fiber, stir and heat, the mechanical stirring speed is 100 rpm, and the heating temperature is 30°C. Time 2h, the solid-to-liquid ratio of polyester fiber and ethyl bromide solution is 1:20, drain after reaction finishes;

[0031] The polyester fiber after draining is added the PVA solution that mass fraction is 4% again, stirs heating, and mechanical stirring speed is 200 rev / mins, an...

Embodiment 2

[0033] A kind of bromoethane and PVA to the hydrophilic modification method of polyester fiber:

[0034] Add a sodium hydroxide solution with a mass fraction of 8% to the polyester fiber, stir and pretreat at 65°C for 2.5 hours, the mechanical stirring speed is 150 rpm, and the solid-to-liquid ratio of the polyester fiber to the sodium hydroxide solution is 1 : 40, rinse with water after pretreatment, and dry at low temperature;

[0035] Add ethyl bromide solution to the polyester fiber after low-temperature drying, add pyridine p-toluenesulfonate solid of 0.02% of the dry weight of the polyester fiber, stir and heat, the mechanical stirring speed is 150 rpm, and the heating temperature is 35°C. Time 3h, the solid-to-liquid ratio of polyester fiber and ethyl bromide solution is 1:30, drain after reaction finishes;

[0036] The polyester fiber after draining is added the PVA solution that mass fraction is 5.5% again, stirring heating, mechanical stirring speed is 250 revs / min,...

Embodiment 3

[0038] A kind of bromoethane and PVA to the hydrophilic modification method of polyester fiber:

[0039] Add a sodium hydroxide solution with a mass fraction of 6% to the polyester fiber, stir and pretreat it at a temperature of 65°C for 2 hours, the mechanical stirring speed is 150 rpm, and the solid-to-liquid ratio of the polyester fiber and the sodium hydroxide solution is 1: 30. Rinse with water after pretreatment, and dry at low temperature;

[0040] Add ethyl bromide solution to the polyester fiber after low-temperature drying, add pyridine p-toluenesulfonate solid of 0.02% of the dry weight of the polyester fiber, stir and heat, the mechanical stirring speed is 100 rpm, and the heating temperature is 35°C. Time 2h, the solid-to-liquid ratio of polyester fiber and ethyl bromide solution is 1:30, drain after reaction finishes;

[0041] The polyester fiber after draining is added the PVA solution that mass fraction is 4% again, stirring heating, mechanical stirring speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com