Method for preparing polypropylene melt with high melt strength

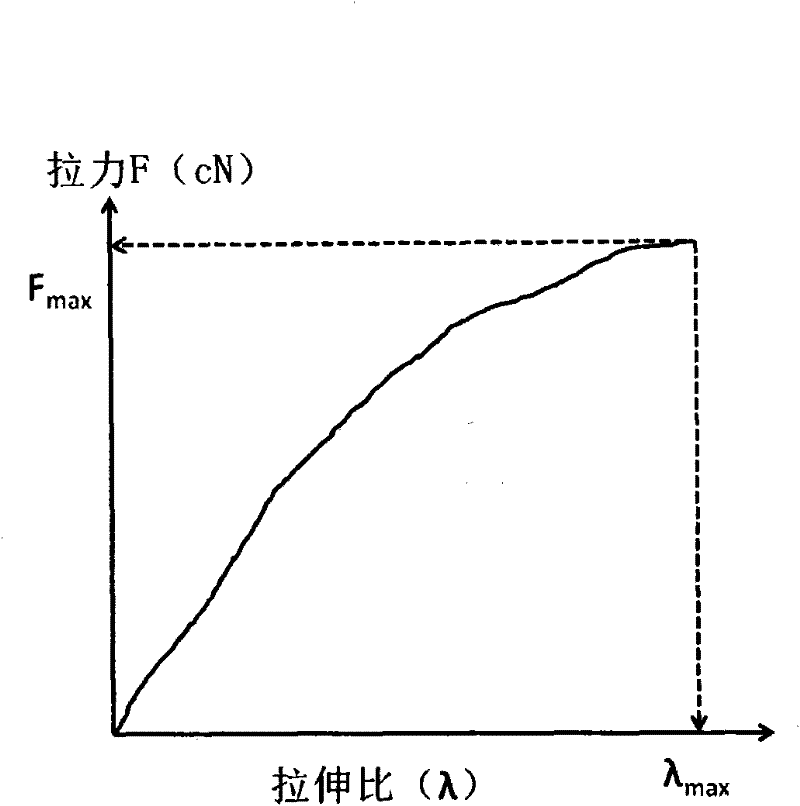

A high melt strength, polypropylene technology, applied in the polypropylene field, can solve the problems of poor compatibility, low polypropylene melt tensile properties, and the cross-linking reaction cannot be well solved, and achieves cross-linking reaction inhibition. , The effect of improving melt tensile properties and excellent melt ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

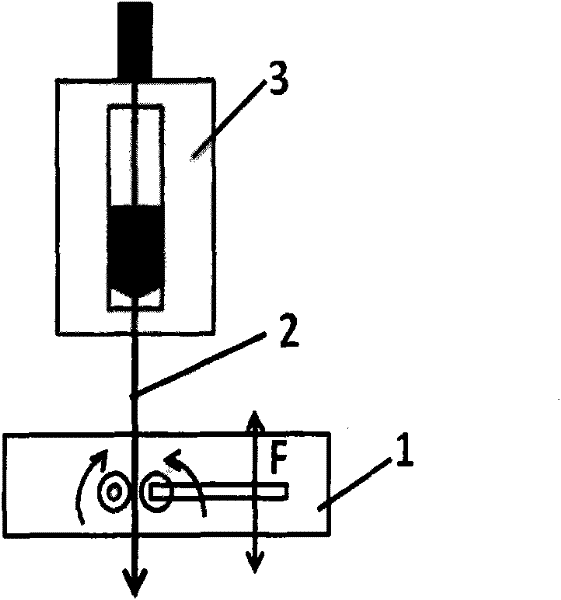

[0032] The embodiment of the present invention discloses a method for preparing a high melt strength polypropylene melt, comprising:

[0033] The raw materials are melt mixed and reacted to produce a high melt strength polypropylene melt, wherein the raw materials include:

[0034] 100 parts by weight of polypropylene;

[0035] 0.5 to 5 parts by weight of diolefins;

[0036] 0.01 to 10 parts by weight of grafted monomers;

[0037] 0.01-3 parts by weight of initiator.

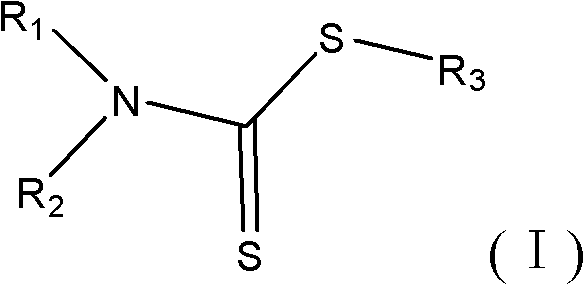

[0038] The grafting monomer preferably includes acrylate and / or other compounds with poor compatibility with polypropylene resin;

[0039] The acrylate preferably includes one or more of monoacrylate, diacrylate, triacrylate and tetraacrylate;

[0040] The monoacrylate preferably comprises one of octyl (meth)acrylate, isooctyl (meth)acrylate, glycidyl (meth)acrylate, 2-ethylhexyl acrylate and allyl acrylate or several;

[0041] The diacrylate preferably comprises one or more of triethylene glycol dimethacr...

Embodiment 1

[0082] 100 parts by weight of polypropylene (homopolypropylene, powder, melt index is 2.2g / 10min), 0.01 parts by weight of trimethylolpropane trimethacrylate, 1.99 parts by weight of isoprene, 0.3 Parts by weight of TBPB and 0.2 parts by weight of antioxidant B215 were evenly mixed and added to an internal mixer at 180°C, kneaded for 10 minutes, and discharged when the torque remained constant to obtain high melt strength polypropylene.

Embodiment 2

[0084] 80 parts by weight of polypropylene (homopolypropylene, powder, melt index 1.5g / 10min), 20 parts by weight of polypropylene (homopolypropylene, powder, melt index 2.2g / 10min), 0.5 parts by weight Parts of trimethylolpropane trimethacrylate, 3.5 parts by weight of piperylene, 0.5 parts by weight of TBPB, 0.2 parts by weight of antioxidant B215, uniformly mixed and added to the twin-screw extruder, wherein extruded The four-stage temperature of the machine from the feed port to the discharge port is 190 ° C, 200 ° C, 180 ° C and 230 ° C respectively, and it is reacted and extruded in a molten state. The reaction time is 3 minutes, and high melt strength polypropylene is produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com