Patents

Literature

33results about How to "Inhibition of cross-linking reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of natural rubber with constant viscosity

InactiveCN101864004AInhibition of cross-linking reactionLow gel contentPolymer scienceMooney viscosity

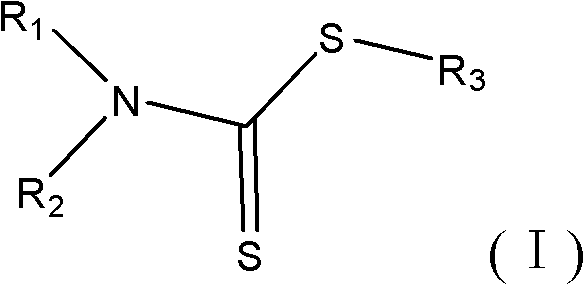

The invention discloses a preparation method of natural rubber with constant viscosity which relates to the technique of mooney viscosity control of natural rubber. The method comprises the steps of adding the mercaptan compounds into the natural rubber, mixing evenly, and then performing the conventional processes of solidification, tabletting, prilling and drying. The natural rubber with constant viscosity of the invention has the storage hardening value of smaller than 2 represented by the Wallace initial plasticity, and has the storage hardening value of smaller than 5 represented by the mooney viscosity, thereby significantly improving the processing characteristics.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

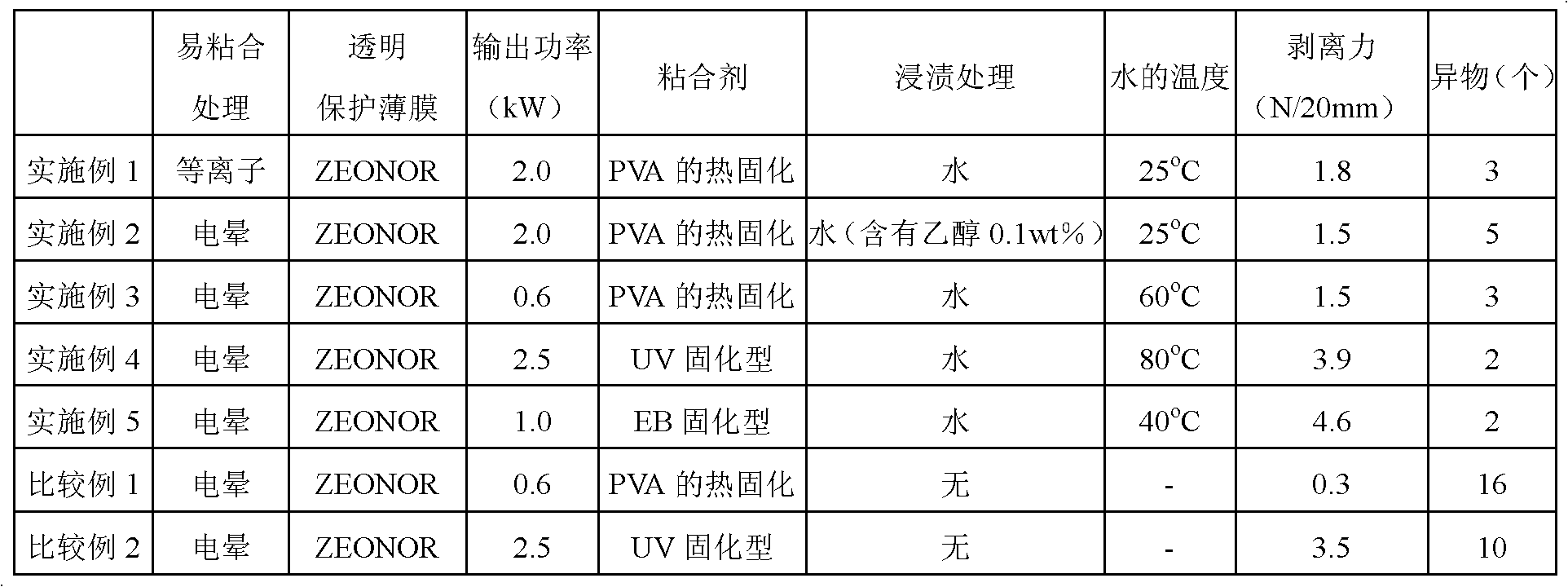

Polarizing plate manufacturing method

InactiveCN102439495AImprove adhesionPrevent floatingPolarising elementsNon-linear opticsPolarizerComposite material

Provided are: a polarizing plate manufacturing method which makes it possible to increase the throughput by preventing adhesion failure between a polarizing film and a transparent protective film even immediately after the transparent protective film is laminated on and adhered to the polarizing film; and a polarizing plate obtained by the method. On the transparent protective film, at least a surface thereof to be attached to the polarizing film is subjected to adhesion improving treatment. Then, water and at least the surface having been subjected to the adhesion improving treatment are brought into contact with each other. Then, the transparent protective film is laminated on the polarizing film in such a manner that a surface on one side of the transparent protective film is attached to the polarizing film, the one side having the surface that has been brought into contact with water and has been subjected to the adhesion improving treatment.

Owner:NITTO DENKO CORP

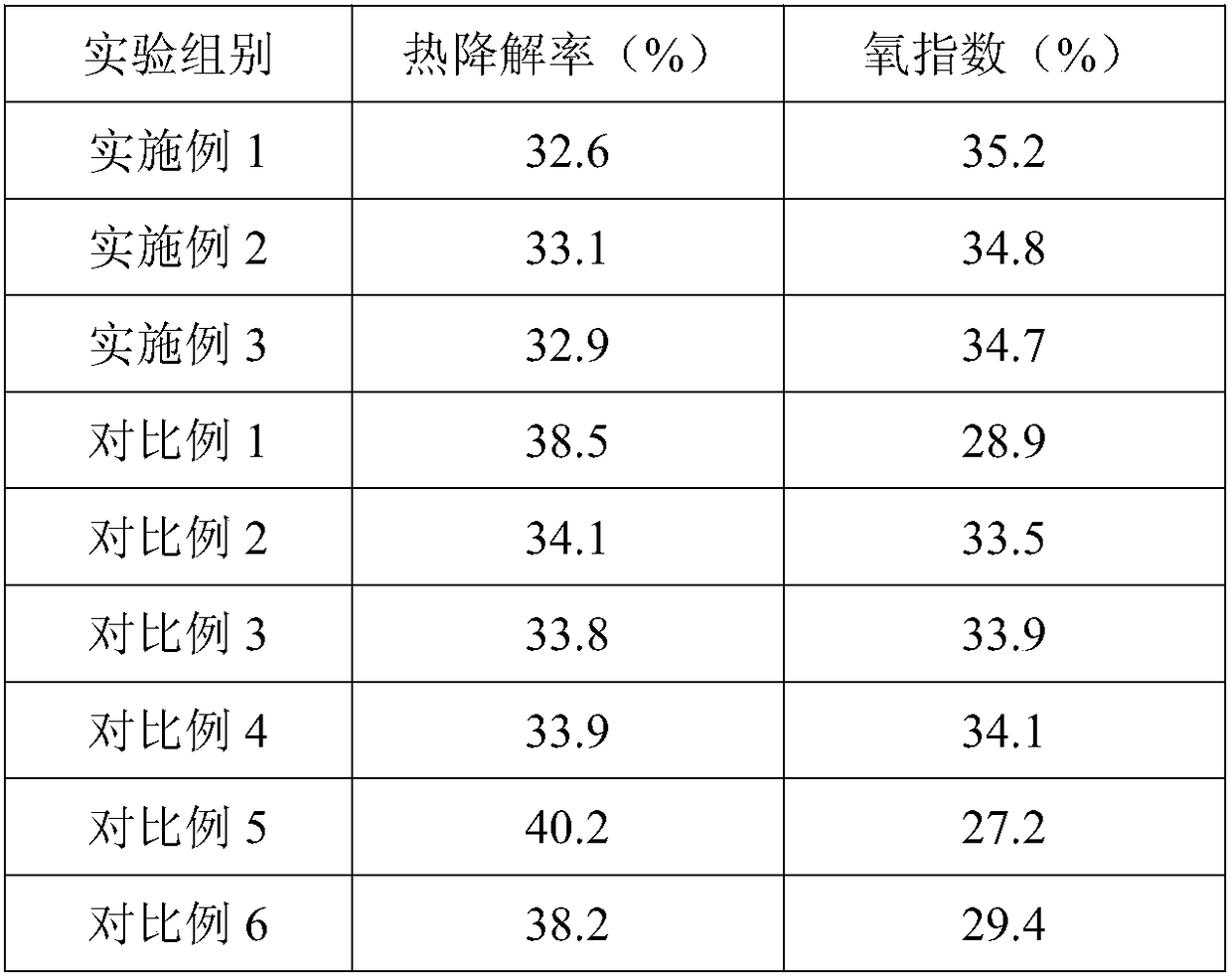

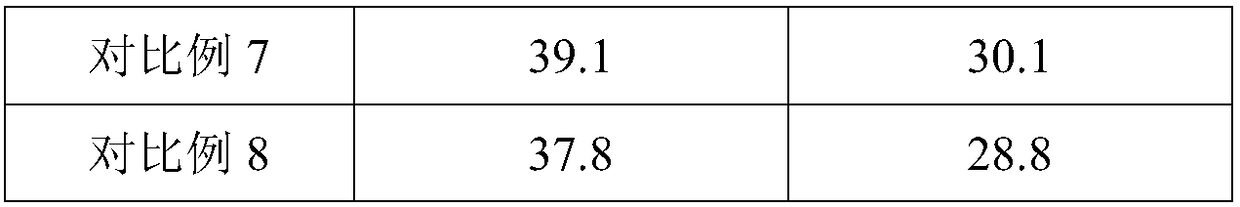

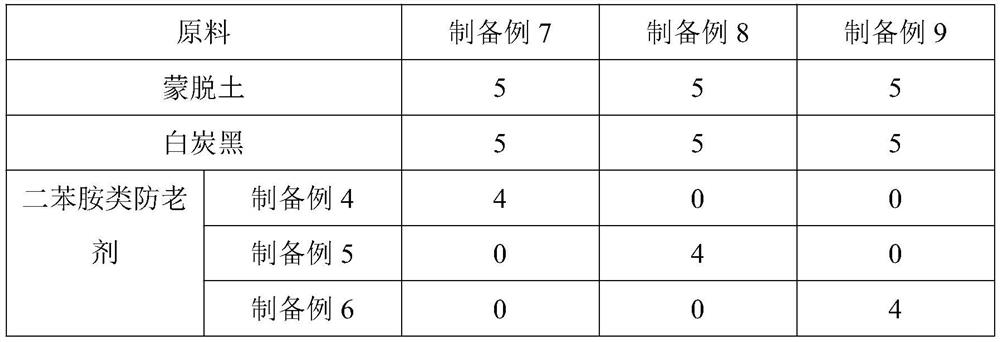

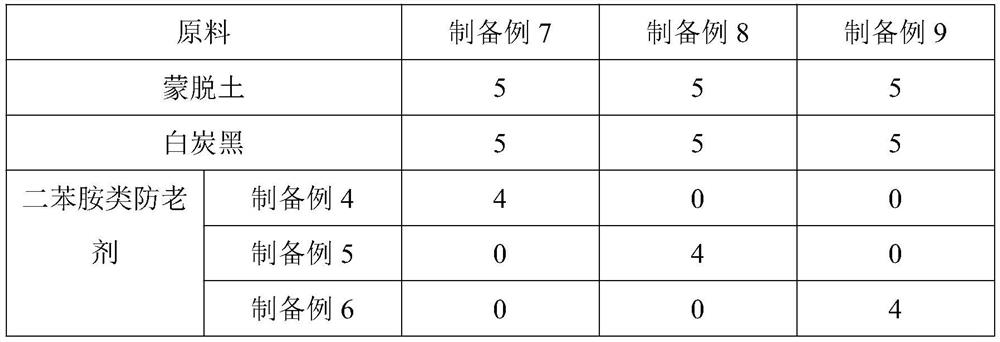

Flame-retardant fireproof wire and cable material and preparation method thereof

InactiveCN109456535ALow thermal degradation rateHigh oxygen indexPlastic/resin/waxes insulatorsAcrylic resinTributyl citrate

The invention belongs to the technical field of wires and cables and discloses a flame-retardant fireproof wire and cable material and a preparation method thereof. The flame-retardant fireproof wireand cable material is prepared from polypropylene resin, modified acrylic resin, methyl vinyl silicon rubber, tributyl citrate, nano silicon dioxide, dicumyl peroxide, platinic hydroxide, polyimide, zinc stearate, a silane coupling agent, white carbon black, an anti-aging agent and an accelerant, wherein a weight ratio of nano silicon dioxide to dicumyl peroxide to platinic hydroxide is (2.2-5.8):(1.5-3.6):(0.5-1.2). By adoption of a reinforcing system formed by nano silicon dioxide, dicumyl peroxide and platinic hydroxide, heat resistance and flame retardation of the flame-retardant fireproofwire and cable material are improved.

Owner:长沙浩然医疗科技有限公司

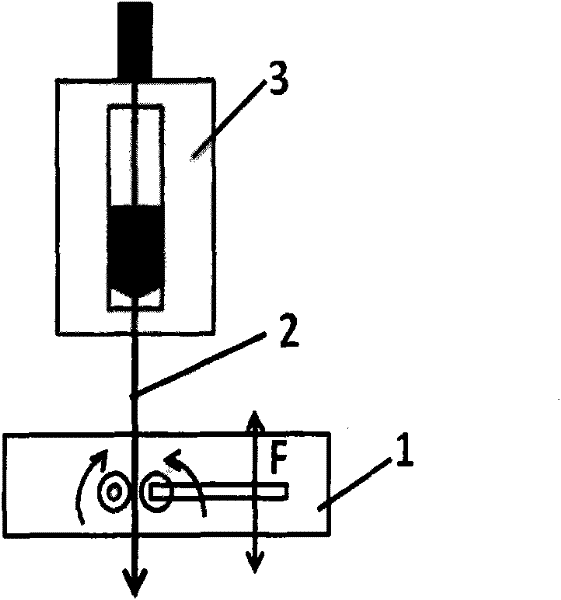

Method for preparing modified polyacrylonitrile ion exchange fibers with electrostatic spinning method

InactiveCN108611691AImprove uniformityIncrease productivityGas treatmentDispersed particle separationPolymer scienceTetramine

The invention discloses a method for preparing modified polyacrylonitrile ion exchange fibers with an electrostatic spinning method and belongs to the technical field of preparation methods of chemical fiber materials. According to the method, polyacrylonitrile is subjected to functional modification firstly, and the ion exchange fibers are directly prepared through electrostatic spinning. The method comprises following steps: polyacrylonitrile is dissolved in a dimethyl formamide solution, triethylene tetramine or diethylenetriamine is added by stirring, a reaction is performed, a modified polyacrylonitrile electrostatic spinning solution is prepared and subjected to electrostatic spinning by an electrostatic spinning device, and the modified polyacrylonitrile electrostatic spinning fibers with the ion exchange function are obtained. The technology is simple, the production efficiency of functional modification of polyacrylonitrile is improved, and uniformity of the ion exchange fibers is improved.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

Preparation method of konjak-glucomannan-based super-water-absorbent granules

The invention discloses a preparation method of konjak-glucomannan-based super-water-absorbent granules. The method comprises the following steps: swelling konjak refined flour with warm water, adding a mixed organic phase composed of cyclohexane and liquid paraffin and Span 80, adding an initiator ammonium persulfate, stirring uniformly, adding sodium-hydroxide-neutralized acrylic acid and N,N-methylene-bis-acrylamide, stirring, heating to 70 DEG C, and reacting for some time; and after the reaction stops, standing the reaction solution to stratify, removing the supernate, cleaning the lower product with water, and drying to obtain the konjak-glucomannan-based super-water-absorbent granules. The konjak-glucomannan-based super-water-absorbent granules have the advantages of uniform particle size, regular shape, favorable granularity, high yield and favorable water absorptivity. The mixed solvent is used as the organic phase to control the granular shape of the product so as to perform one-step granulation, thereby omitting the subsequent granulation process; and thus, the preparation technique has the advantages of simple process, fewer side reactions and low production energy consumption, and is convenient for preparation and application of KASP.

Owner:SHAANXI UNIV OF SCI & TECH

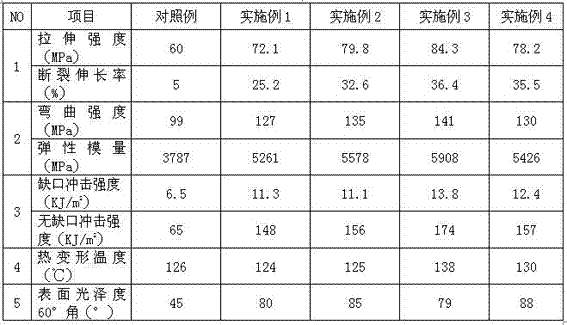

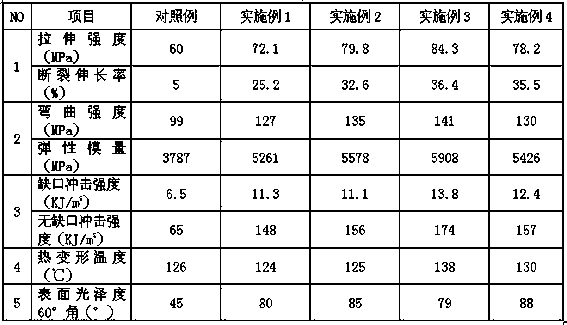

High fatigue resistance nylon composite material for office seats and preparation method thereof

The invention discloses a high fatigue resistance nylon composite material for office seats and a preparation method thereof and belongs to the technical field of high molecular materials. The nylon composite material is prepared by utilizing polyamide, a chain extender, an additive and inorganic mineral powder modified by a silane coupling agent as raw materials and melting and extruding out by atwin-screw extruder. The method has the advantages of simpleness in operation and convenience in process; furthermore, the material has the excellent performance of excellent mechanical property, good appearance, low production cost and the like.

Owner:杭州金州高分子科技有限公司

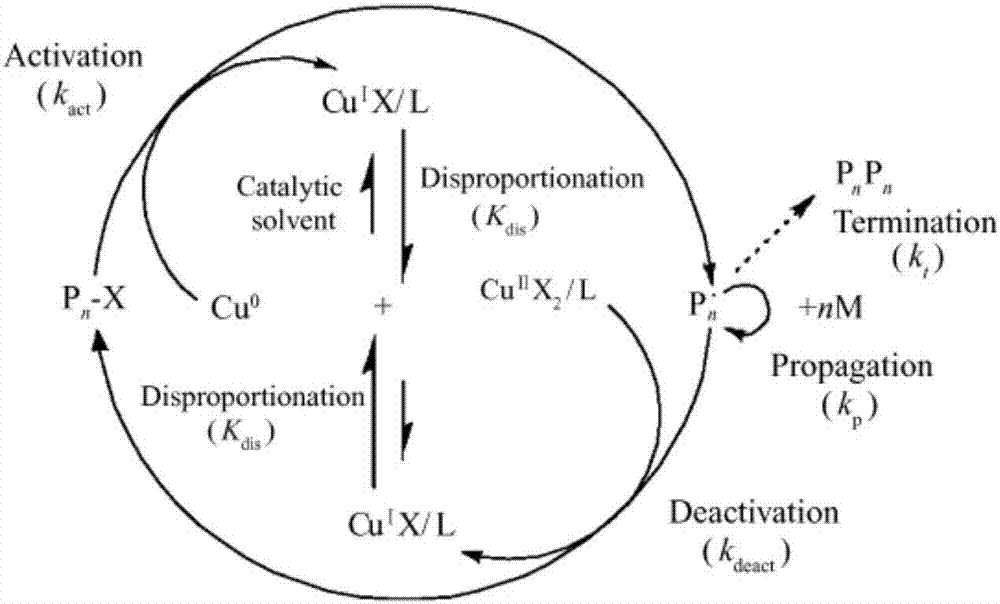

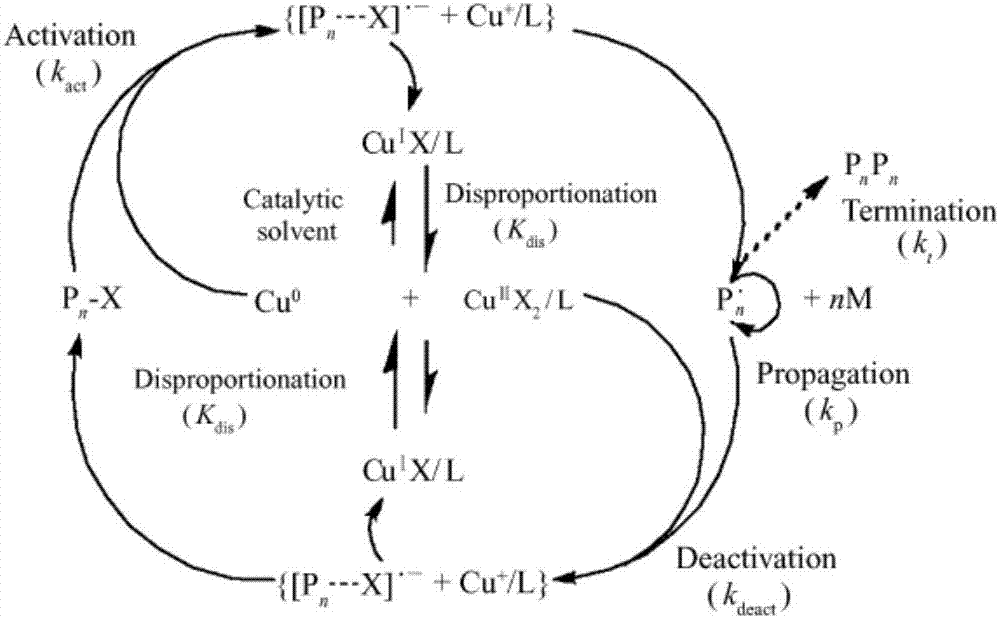

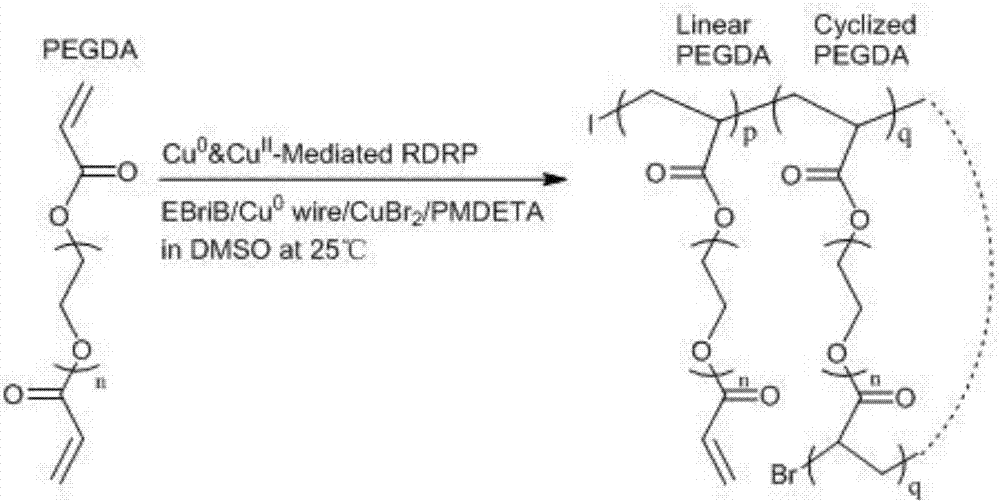

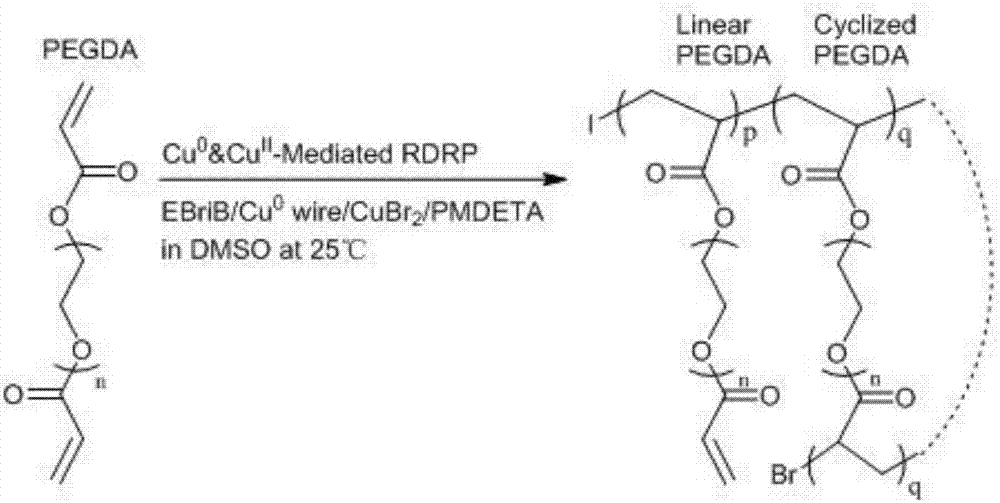

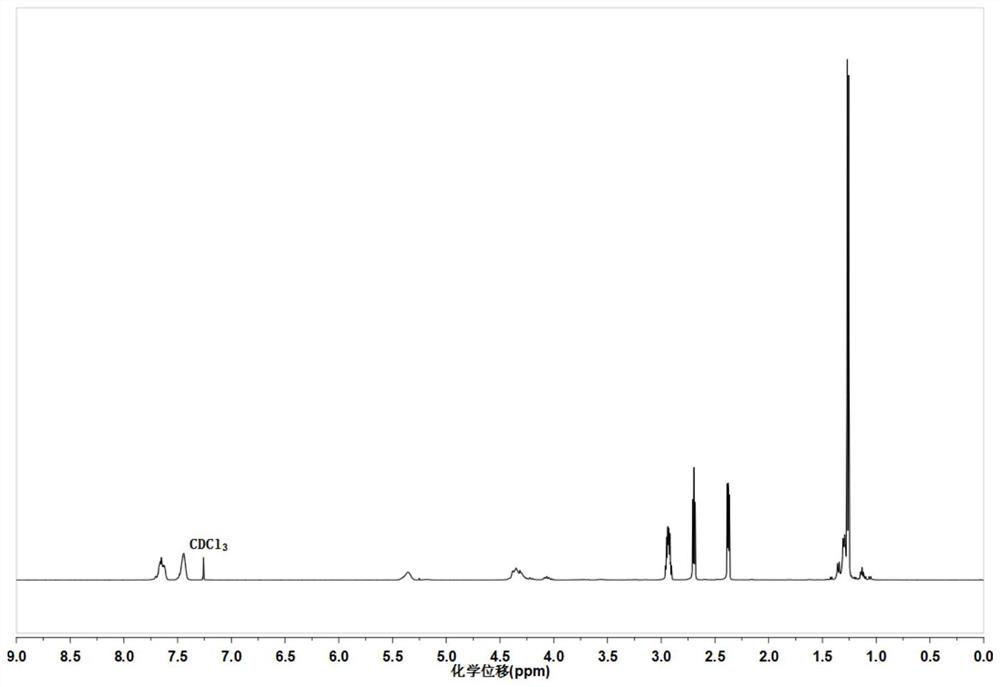

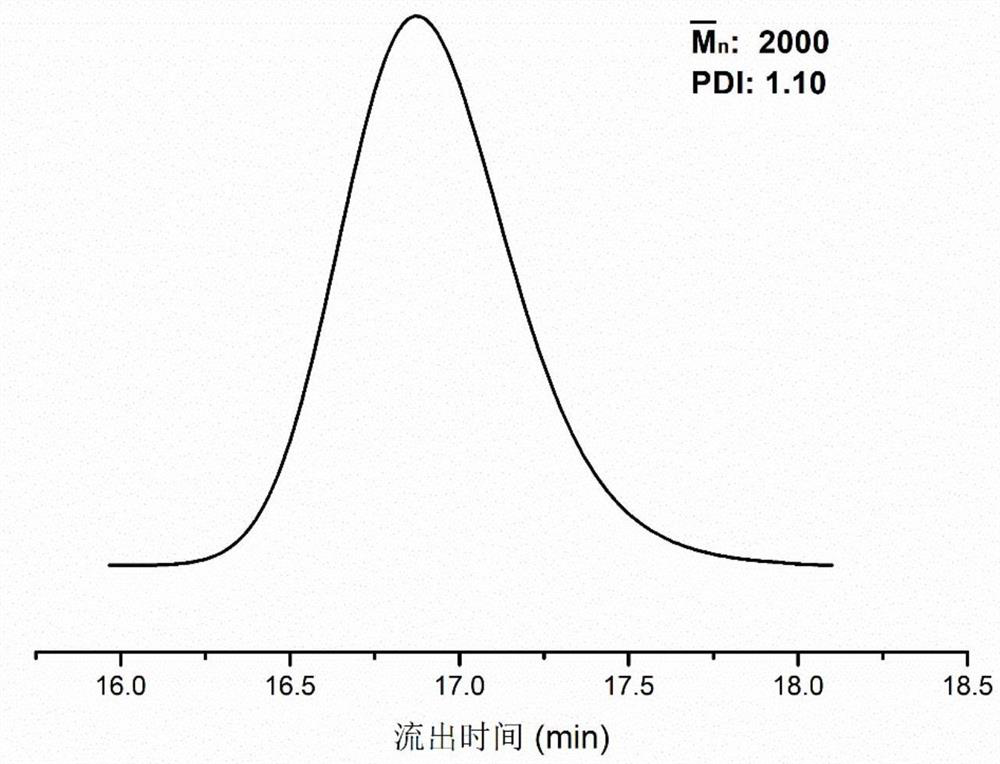

Hydrogel based on single-stranded ultra-internal cyclopolymer and application of hydrogel

InactiveCN106893018AImprove adhesion strengthReduce swellingSurgical adhesivesAbsorbent padsCross-linkWound dressing

The invention discloses hydrogel based on a single-stranded ultra-internal cyclopolymer and application thereof. The single-stranded ultra-internal cyclopolymer obtained by homopolymerizing monomer polyethylene glycol diacrylate by adopting a controllable reactive radical polymerization method for zero-valent copper regulation and control is taken as a precursor, 2,2-dimethoxy-phenylacetophenone is taken as an ultraviolet light initiator, water is taken as a solvent, and carbon-carbon double bonds in the precursor are initiated under the irradiation of ultraviolet light for cross-linking to form a hydrogel material. The characterization of the polymer proves that a constant of a Mark-Hovink formula of the single-stranded ultra-internal cyclopolymer is 0.5, and the structure of the single-stranded ultra-internal cyclopolymer is similar to a spherical shape. Known from an ultraviolet light-rheology joint test, the single-stranded ultra-internal cyclopolymer can be quickly formed, is of a highly-cyclized structure and has higher storage modulus through a large amount of vinyl; the hydrogel has higher adhesion strength, lower swelling property, slower degradation property and better cell compatibility, and can be used as a wound dressing or a tissue adhesive.

Owner:TIANJIN UNIV

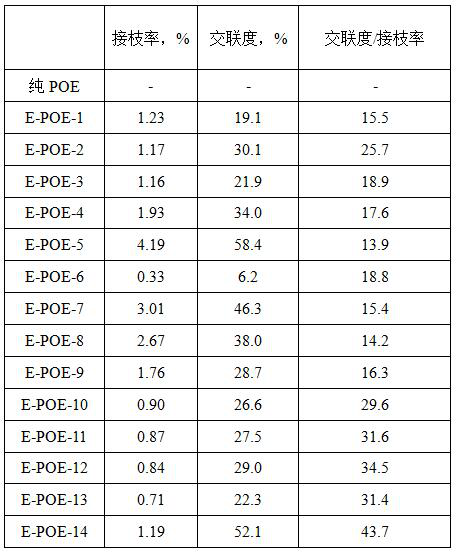

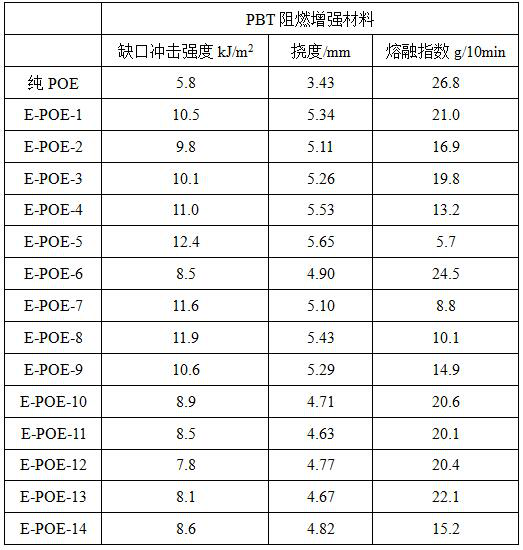

Toughening agent composition and preparation method thereof

ActiveCN111825801AImprove liquidityInhibition of self-aggregationPolymer scienceGlycidyl methacrylate

The invention discloses a toughening agent composition, which comprises, by weight, 0.2%-10.0% of a styrene monomer, 0.5%-10.0% of a glycidyl methacrylate monomer and / or glycidyl methacrylate derivative monomer, 49.5%-94.0% of an ethylene-octene copolymer, 5.0%-49.5% of polyethylene and / or polypropylene and 0.2%-10.0% of talcum powder. By adding the talcum powder, the grafting rate of the epoxidized ethylene-octene copolymer, the epoxidized polyethylene and / or the epoxidized polypropylene in the toughening agent composition is guaranteed while the cross-linking degree is reduced; and the melting point of the initiator is further optimized, so that the cross-linking degree is further reduced.

Owner:KINGFA SCI & TECH CO LTD

Method for preparing polypropylene melt with high melt strength

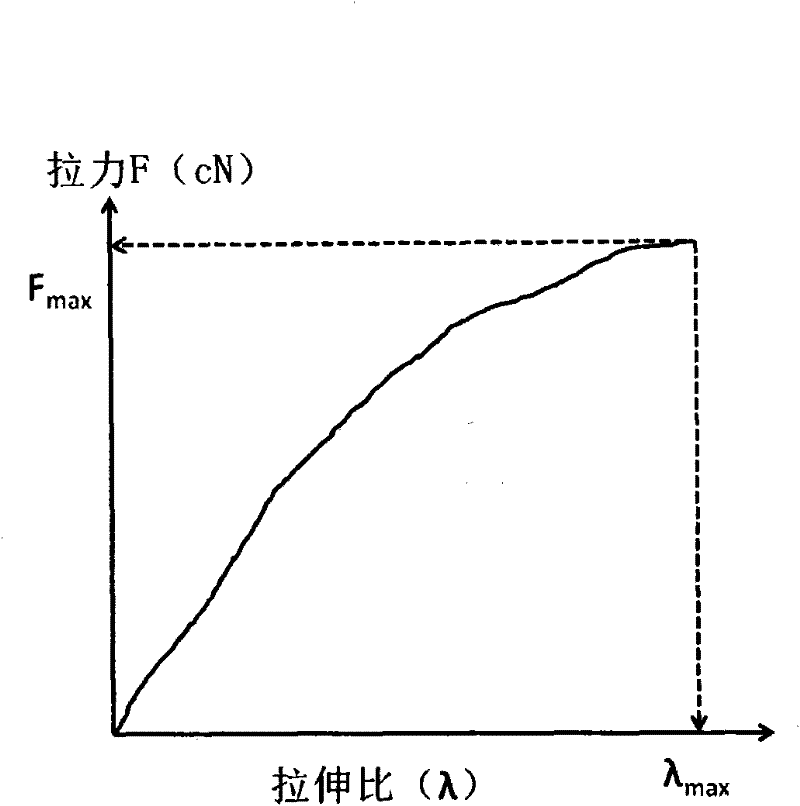

The embodiment of the invention discloses a method for preparing polypropylene melt with high melt strength, which uses alkadiene as a modified monomer, thus improving the tensile property of the polypropylene melt with high melt strength due to good compatibility of the alkadiene and polypropylene resin. In addition, the alkadiene monomers can perform grafting reaction with the polypropylene melt, and the alkadiene monomer has lower activity, thus inhibiting cross-linkage reaction so as to expedite the grafting reaction in a certain degree and ensure polypropylene to have higher melt strength. Therefore, the polypropylene melt with high melt strength prepared by the method provided by the invention not only has higher melt strength, but also has larger draw ratio and excellent melt ductility.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

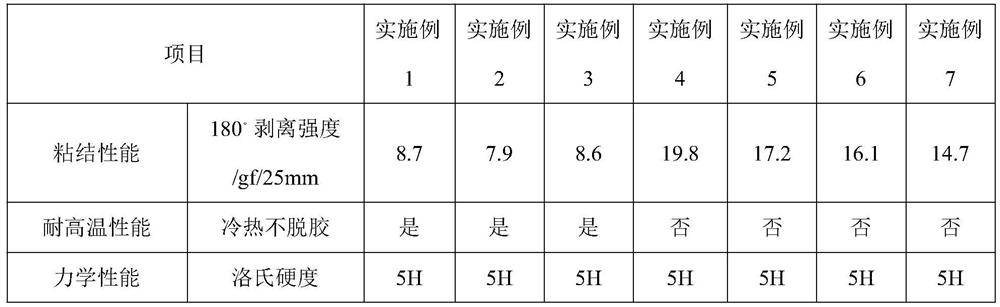

Low viscosity PET protective film for foaming body material

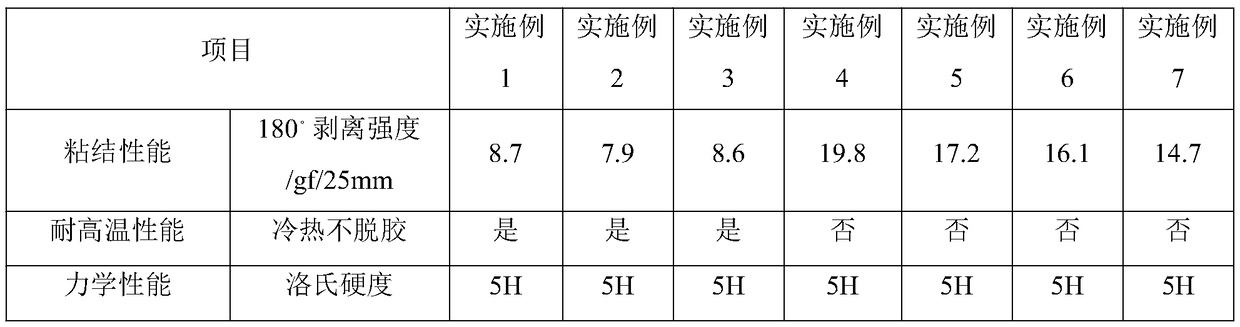

ActiveCN108822757ASimple preparation processEasy to operateFilm/foil adhesivesAlcoholTemperature resistance

The invention provides a low viscosity PET protective film for a foaming body material. The low viscosity PET protective film for the foaming body material comprises a PET base material layer, a low viscosity middle layer and a protective layer, has the advantages of simple preparation process and easy operation and is suitable for industrial production. Firstly, a chain extender of a high-performance low viscosity glue is acidic, an acidic substance can inhibit formation reaction of biuret so as to inhibit cross-linking reaction, and therefore, the viscosity is reduced; and secondly, a catalyst is a mild acidic ion liquid, the catalytic activity of the catalyst is lower, the nucleophilic attack of the catalyst to isocyanate is effectively inhibited so as to reduce the activity of reactionof the isocyanate and macromolecular dihydric alcohol hydroxy, the catalyst has a better synergistic effect with an emulsifying agent, the viscosity of the product is reduced, and the storage and stability performances of the high-performance low viscosity glue are improved. Therefore, the low viscosity PET protective film for the foaming body material, provided by the invention, has the advantages of low viscosity, easy tearing, no residual glue, good conformability, good high temperature resistance and excellent mechanical property.

Owner:NINGBO KELAIEN NEW MATERIAL TECH CO LTD

Epoxy ethylene-octene copolymer composition and preparation method thereof

The invention provides an ethylene oxide-octene copolymer composition, which comprises the following components by weight: 0.2%-10.0% of a styrene monomer, 0.5%-10.0% of a glycidyl methacrylate monomer and / or glycidyl methacrylate derivative monomer, 70.0%-99.0% of an ethylene-octene copolymer and 0.2%-10.0% of talcum powder. According to the invention, by adding the talcum powder, the grafting rate of the ethylene oxide-octene copolymer is guaranteed while the cross-linking degree is reduced; and the melting point of the initiator is further optimized, so that the cross-linking degree is further reduced.

Owner:KINGFA SCI & TECH CO LTD

Grafted polypheylene ether resin and preparation method thereof

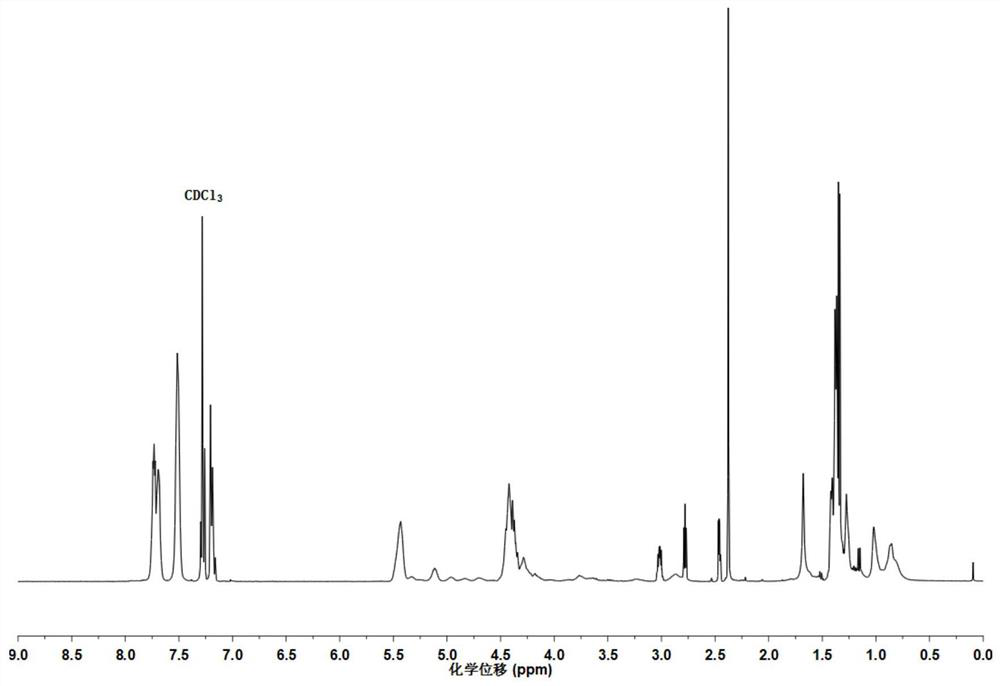

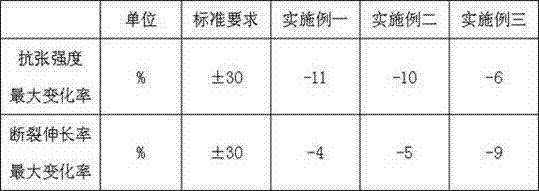

ActiveCN102516469AUniform concentration distributionAvoid cross-linking reactionsPre irradiationCross-link

The invention relates to a grafted polyphenylene ether resin and a preparation method thereof, and belongs to the field of a polyphenylene ether resin. In the prior art, the chains of the polyphenylene ether molecules are easy to cross-link, the monomer is easily subjected to homopolymerization, and the mechanical property of the grafted polyphenylene ether resin is poor. The purpose of the present invention is to solve the problems in the prior art. The preparation method comprises: adopting beta rays or gamma rays to carry out pre-irradiation on the polyphenylene ether resin; mixing the pre-irradiated polyphenylene ether resin and the polyphenylene ether resin, and adding the resulting mixture to a reaction type double screw extruder; adding a graft monomer and an electron donor from a liquid feeding port of the reaction type double screw extruder to carry out reactive extrusion grafting to obtain the grafted polyphenylene ether resin. The water contact angle of the grafted polyphenylene ether resin prepared by the method is in the range of 50.6-82.6 DEG C, and the tensile strength of the grafted polyphenylene ether resin / polyamide 6 blending alloy can be 71.4 Mpa.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

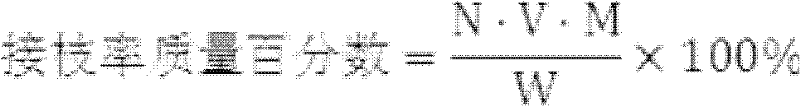

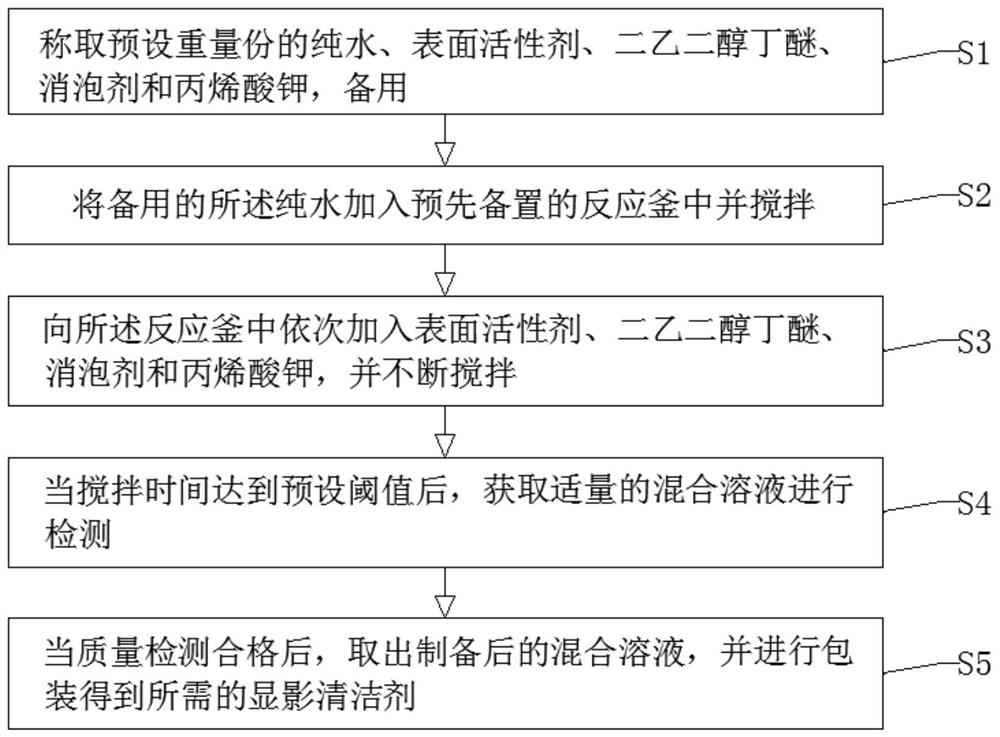

Developing cleaning agent and preparation method thereof

PendingCN112980594AInhibition of cross-linking reactionAvoid formingOrganic detergent compounding agentsSurface-active detergent compositionsDiethylene glycol monobutyl etherActive agent

The invention discloses a developing cleaning agent and a preparation method thereof. The developing cleaning agent is prepared from the following raw materials in parts by weight: 75-85 parts of pure water, 10-20 parts of a surfactant, 1-3 parts of diethylene glycol monobutyl ether, 0.05-0.15 part of a defoaming agent and 1-3 parts of potassium acrylate. The developing cleaning agent disclosed by the invention has the beneficial effects that the developing cleaning agent is a liquid medicine for improving the anti-adhesion of a dry film / wet film and ink, and can effectively inhibit the cross-linking reaction of a photosensitive polymer dissolved in a developing solution and avoid the formation of a polymer by cross combination of monomers, so that unpolymerized photoresist in a bath solution does not continue to generate a secondary polymerization reaction in a specific environment so as to reduce the proportion of poor quality caused by the anti-adhesion of the residual glue; and the developing cleaning agent disclosed by the invention can also be used for cleaning a groove body, so that line edges of a developing pattern are more neat and smoother, and the quality is improved.

Owner:江西博泉化学有限公司

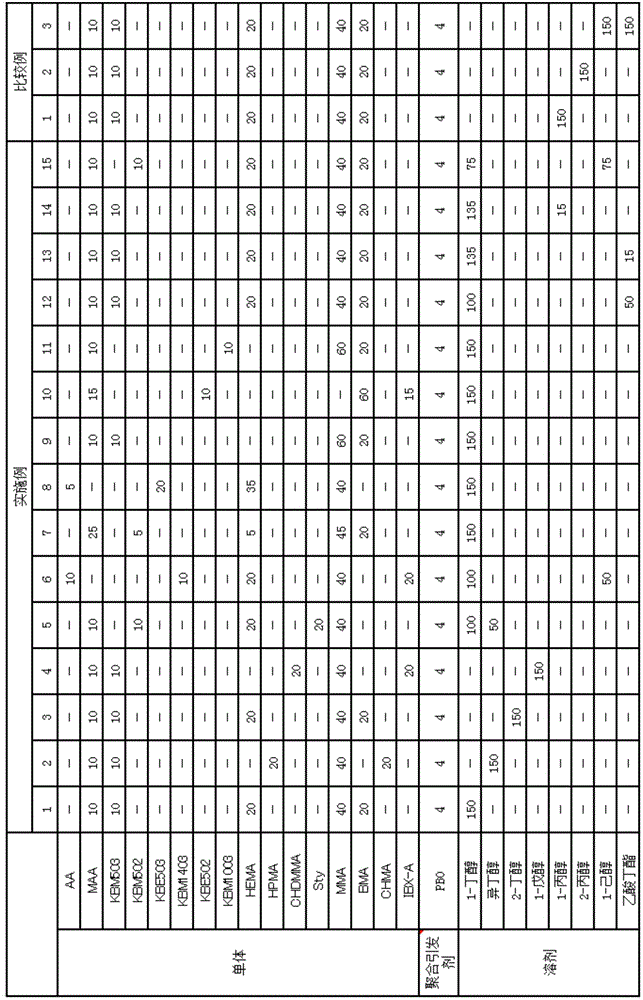

Alkali-soluble resin, photosensitive resin composition, and use thereof

This alkali-soluble resin comprises a copolymer dissolved in a solvent, the copolymer including a polymeric unit containing a carboxyl group based on an unsaturated carboxylic acid, etc. and a polymeric unit containing an alkoxysilyl group based on a monomer of formula (1) below. The solvent is a specific alcohol having a linear or branched chain alkyl group having 4 or 5 carbon atoms. The specific alcohol is preferably a primary alcohol with an alkyl group having 4 carbon atoms, and more preferably 1-butanol. X-(CH2)a-Si(OR)b(CH3)3-b (1) In formula (1), X is a vinyl group, styryl group, or (meth)acryloyl group, R is a methyl group or ethyl group, a is an integer of 0-3, and b is an integer of 1-3.

Owner:NATOCO

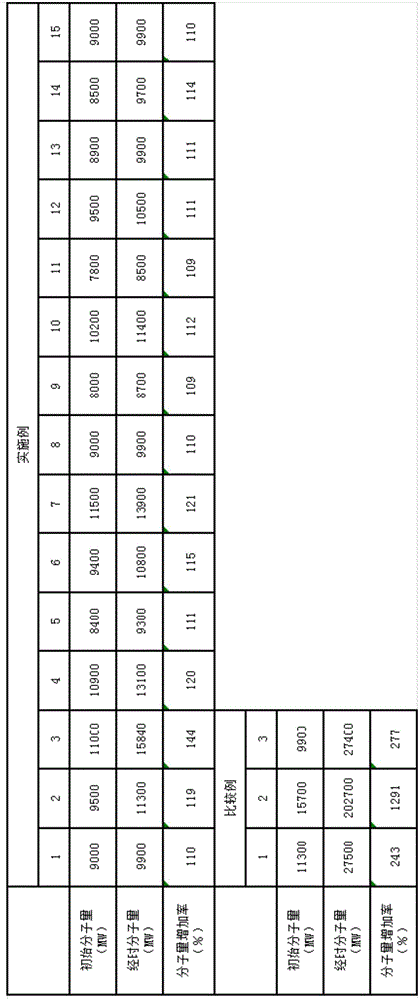

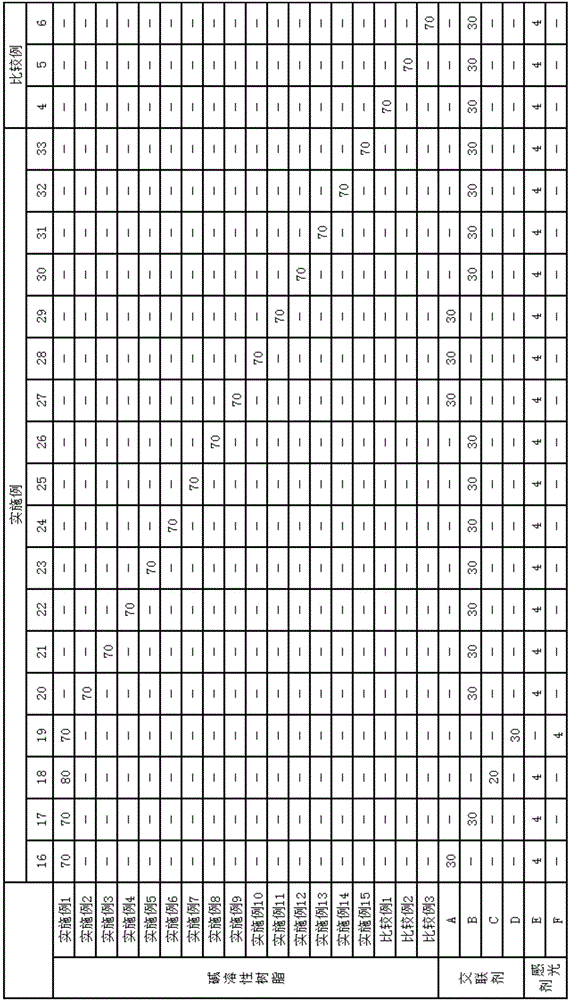

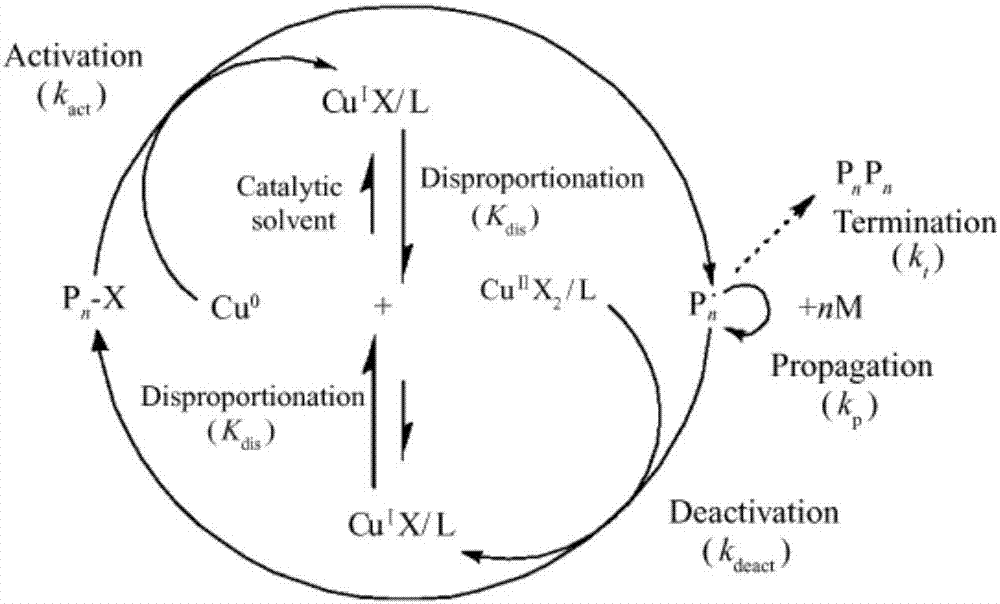

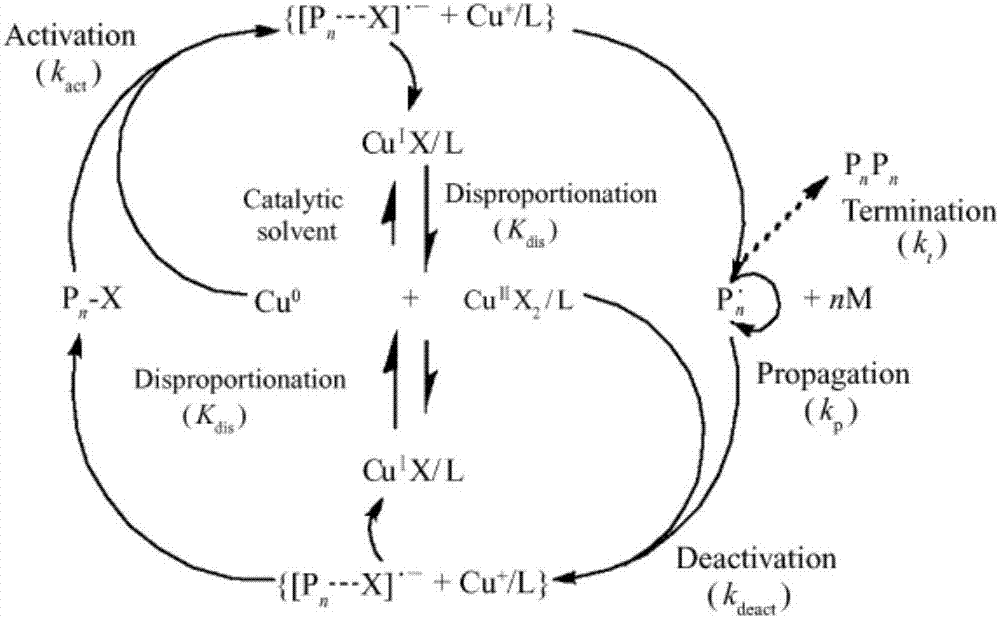

Single-chain super intramolecular cyclization polymer, and preparation method thereof

InactiveCN106947011AImprove adhesion strengthReduce swellingSurgical adhesivesBandagesPolymer scienceUltraviolet lights

The invention discloses a single-chain super intramolecular cyclization polymer, and a preparation method thereof. According to the preparation method, polyethyleneglycol diacrylate is taken as a monmer, zero valent copper adjusted controllable active free radical polymerization is adopted for polymerization of monmer polyethyleneglycol diacrylate, chain growth and intramolecular cyclization are promoted, intermolecular cross-linking is inhibited, and the single-chain super intramolecular cyclization polymer is obtained. According to the single-chain super intramolecular cyclization polymer, linear polyethyleneglycol diacrylate and annular polyethyleneglycol diacrylate are formed in polymer single chains. It is shown by polymer characterization that: the Mark-Houwink Equation constant is lower than 0.5, the structure of the single-chain super intramolecular cyclization polymer is similar to spherality, and a hydrogel material can be prepared via solidification of a polymer aqueous solution via ultraviolet light crosslinking.

Owner:TIANJIN UNIV

A high fatigue-resistant nylon composite material for office chairs and its preparation method

The invention discloses a high fatigue resistance nylon composite material for office seats and a preparation method thereof and belongs to the technical field of high molecular materials. The nylon composite material is prepared by utilizing polyamide, a chain extender, an additive and inorganic mineral powder modified by a silane coupling agent as raw materials and melting and extruding out by atwin-screw extruder. The method has the advantages of simpleness in operation and convenience in process; furthermore, the material has the excellent performance of excellent mechanical property, good appearance, low production cost and the like.

Owner:杭州金州高分子科技有限公司

A kind of preparation method of copolyester polyurethane

The invention belongs to the technical field of polymer synthesis, and more specifically relates to a preparation method of copolyester polyurethane. Using thiourea compounds and organic bases to form a composite catalytic system, using water or diols as chain transfer agents, under milder conditions to co-catalyze the copolymerization of acid anhydride monomers and epoxy monomers to prepare low-alternative structures. Molecular weight copolyester diol; the composite catalytic system further catalyzes the polyaddition reaction of low molecular weight copolyester diol and diisocyanate to synthesize copolyester polyurethane. The process is a "one pot, two steps" process. As a result, the traditional production process of polyester polyurethane can effectively solve the defects of cumbersome steps, time-consuming and laborious, difficult separation and purification, low yield, and high production cost.

Owner:HUAZHONG UNIV OF SCI & TECH

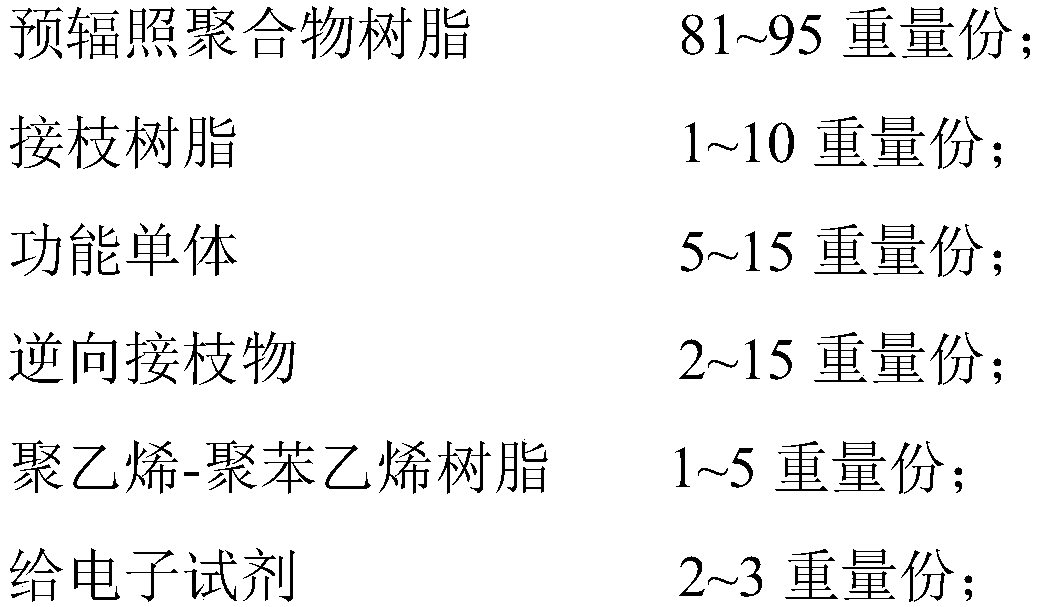

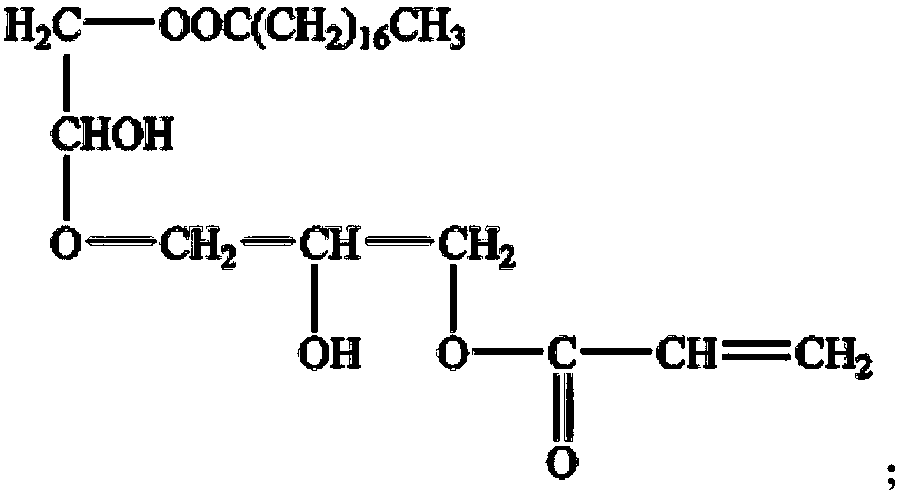

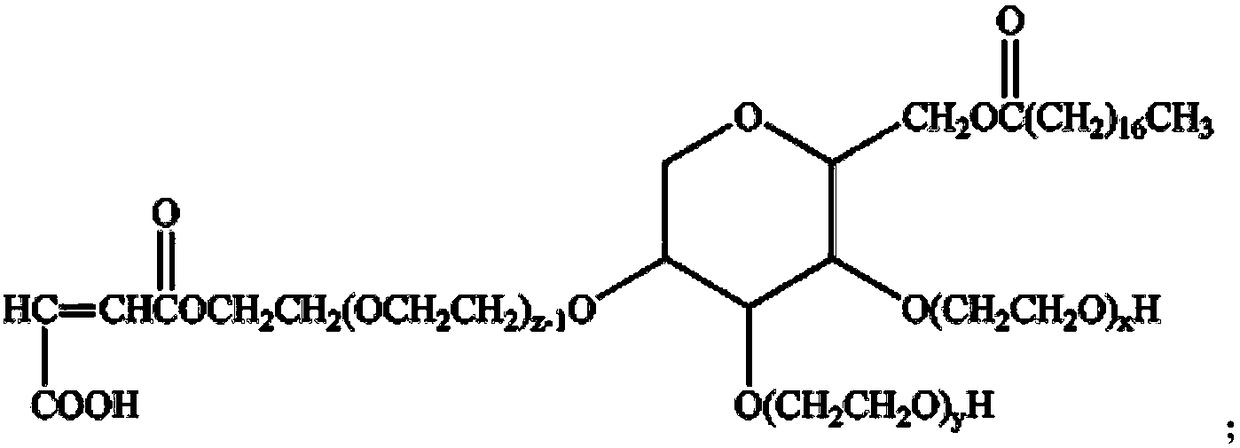

Resin for dripping film, and preparation method and application thereof

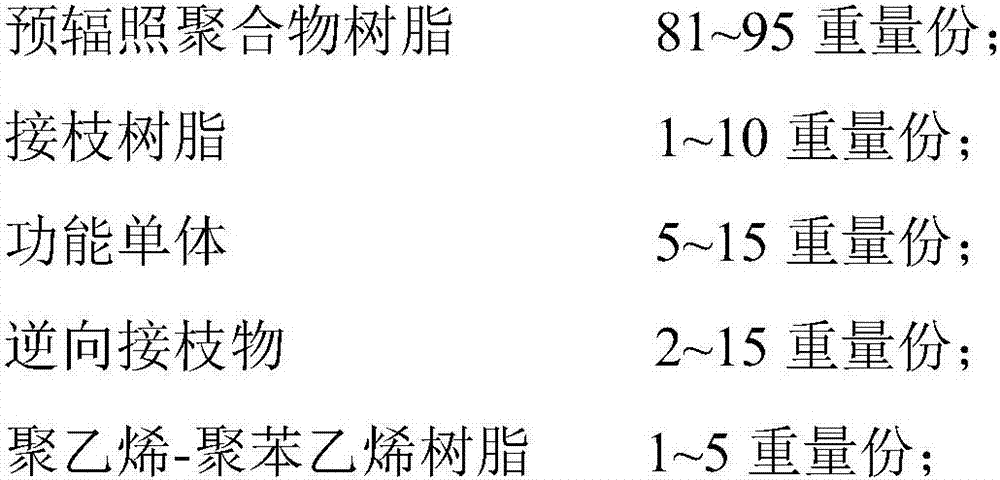

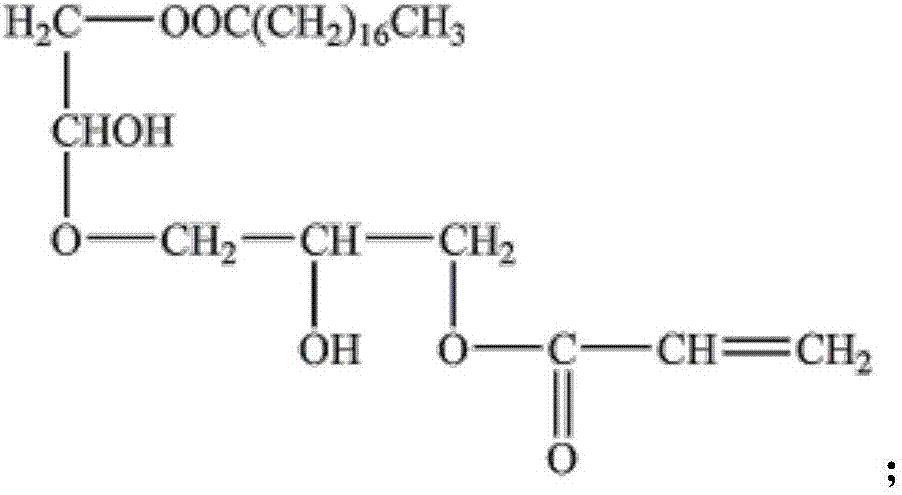

ActiveCN107226891AOvercome precipitationOvercome the disadvantages of migration and water lossPre irradiationPolymer resin

The invention relates to resin for a dripping film, and a preparation method and application thereof, belonging to the technical field of agricultural materials. The objective of the invention is to overcome technical problems in preparation of dripping films with low cost and long dripping period. The resin for the dripping film in the invention is composed of, by weight, 81 to 95 parts of pre-irradiation polymer resin, 1 to 10 parts of grafted resin, 5 to 15 parts of functional monomers, 2 to 15 parts of a reverse graft, 1 to 5 parts of polyethylene-polystyrene resin and 2 to 3 parts of an electron-donating agent, wherein the weight parts of the pre-irradiation polymer resin, the grafted resin, the polyethylene-polystyrene resin and the reverse graft sum to 100. The invention further provides a preparation method for the resin and application of the resin as a dripping-film material. Results of an accelerated dripping experiment at 60 DEGC and an actual outdoor in-greenhouse experiment show that a dripping film prepared from the resin has a dripping period of 29 to 38 days and 12 to 14 months, respectively.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

High-swing data line and preparation method thereof

ActiveCN112979891AHigh tensile strengthImprove toughnessInsulated cablesCable/conductor manufactureElastomerInjection moulding

The invention relates to the technical field of communication transmission equipment, and particularly discloses a high-swing data line and a preparation method thereof. The high-swing data line comprises a conductive wire core, which is coated with a high-swing TPE material, wherein the high-swing TPE material is prepared from the following raw materials in parts by weight: 20-40 parts of SEBS elastomer, 10-20 parts of polypropylene, 5-10 parts of calcium carbonate, 5-10 parts of maleic anhydride, 2-4 parts of a grafting auxiliary agent and 3-5 parts of an anti-wrinkle agent. The preparation method comprises the following steps: melting and extruding a high-swing TPE material, wrapping the high-swing TPE material on a conductive wire core, welding the conductive wire core with a USB joint and a transmission joint, and carrying out injection molding on the conductive wire core and the high-swing TPE material to obtain the high-swing data line. According to the invention, the high-swing data line provided by the invention has relatively good tensile strength, elongation at break and tear strength, and is not easy to crack; and the preparation method is simple to operate, and breakage of the high-swing data line can be further reduced.

Owner:SHENZHEN TARGE IND CO LTD

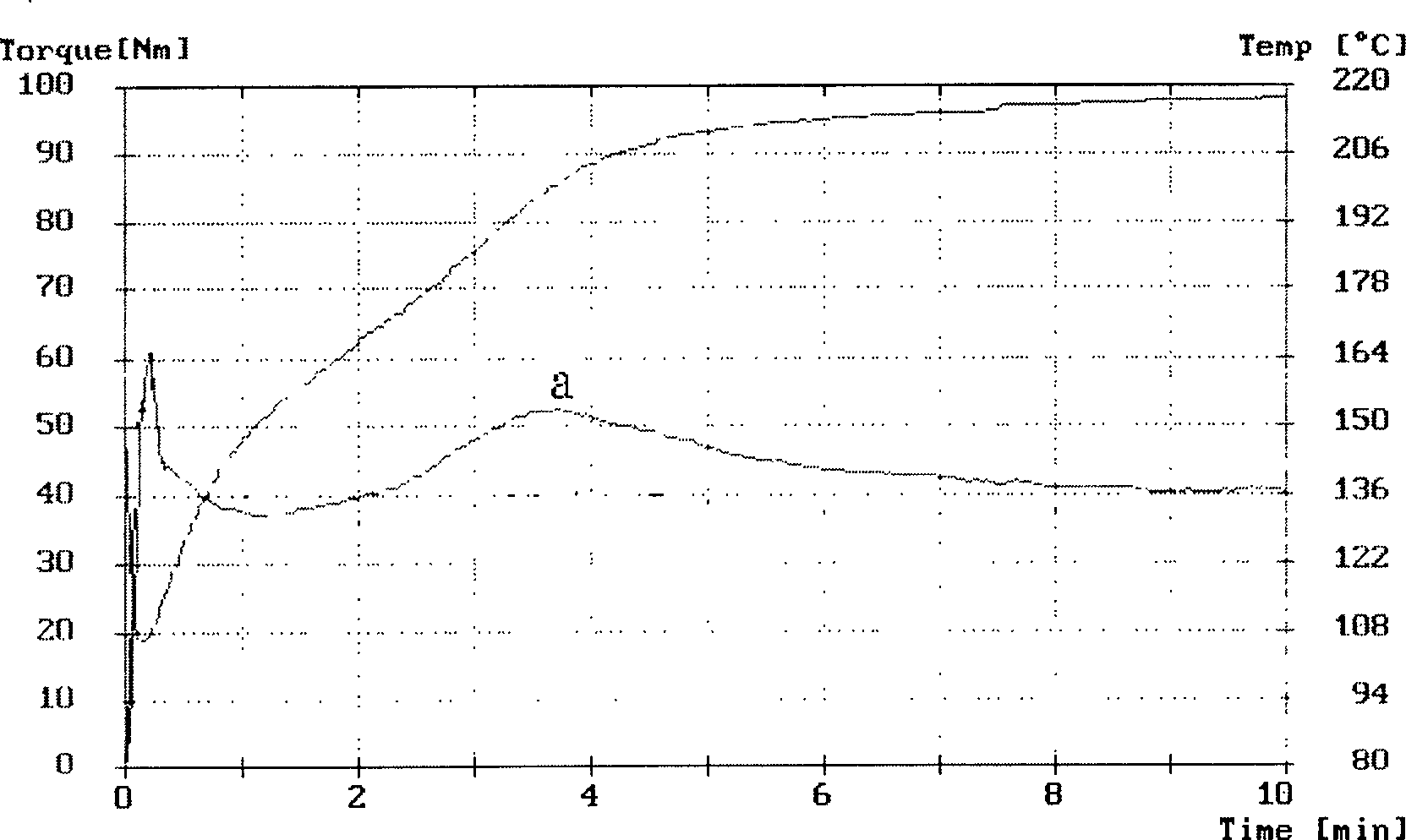

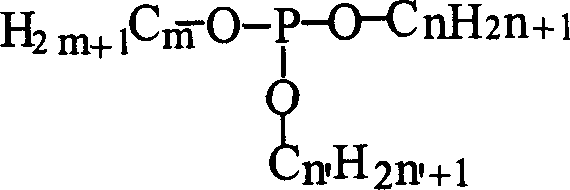

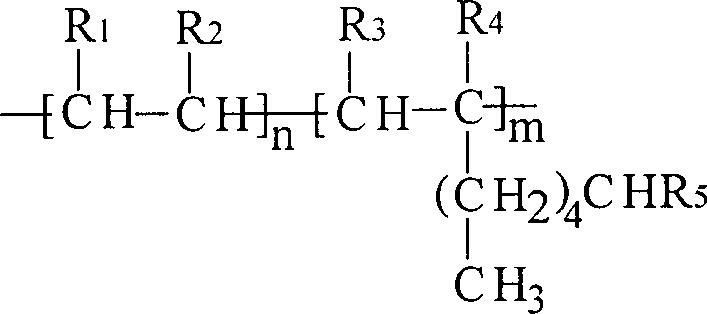

Prepn. of maleic anhydride grafted ethylene-alpha-octylene copolymers

The invented graft copolymer of maleic anhydride and ethylene-alpha-octylene is prepared as follows: ethylene-alpha-octylene copolymer, maleic anhydride peroxide type initiator and phosphite ester like compound are put in extruder ar internal mixer to proceed melt grafting reaction to obtain maleic anhydride graft ethylene-alpha-octylene copolymer. Said method is high in grafting rate, low in gel content.

Owner:SHANGHAI CHLOR ALKALI CHEM

Preparation method of natural rubber with constant viscosity

InactiveCN101864004BInhibition of cross-linking reactionLow gel contentPolymer scienceMooney viscosity

The invention discloses a preparation method of natural rubber with constant viscosity which relates to the technique of mooney viscosity control of natural rubber. The method comprises the steps of adding the mercaptan compounds into the natural rubber, mixing evenly, and then performing the conventional processes of solidification, tabletting, prilling and drying. The natural rubber with constant viscosity of the invention has the storage hardening value of smaller than 2 represented by the Wallace initial plasticity, and has the storage hardening value of smaller than 5 represented by themooney viscosity, thereby significantly improving the processing characteristics.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Grafted polypheylene ether resin and preparation method thereof

ActiveCN102516469BUniform concentration distributionAvoid cross-linking reactionsCross-linkPolymer science

The invention relates to a grafted polyphenylene ether resin and a preparation method thereof, and belongs to the field of a polyphenylene ether resin. In the prior art, the chains of the polyphenylene ether molecules are easy to cross-link, the monomer is easily subjected to homopolymerization, and the mechanical property of the grafted polyphenylene ether resin is poor. The purpose of the present invention is to solve the problems in the prior art. The preparation method comprises: adopting beta rays or gamma rays to carry out pre-irradiation on the polyphenylene ether resin; mixing the pre-irradiated polyphenylene ether resin and the polyphenylene ether resin, and adding the resulting mixture to a reaction type double screw extruder; adding a graft monomer and an electron donor from a liquid feeding port of the reaction type double screw extruder to carry out reactive extrusion grafting to obtain the grafted polyphenylene ether resin. The water contact angle of the grafted polyphenylene ether resin prepared by the method is in the range of 50.6-82.6 DEG C, and the tensile strength of the grafted polyphenylene ether resin / polyamide 6 blending alloy can be 71.4 Mpa.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

A kind of high-performance low-viscosity preparation method for low-viscosity pet protective film

ActiveCN108864968BSimple preparation processEasy to operatePolyureas/polyurethane adhesivesFilm/foil adhesive release linersPolymer sciencePtru catalyst

The invention provides a high-performance low-viscosity preparation method for low-viscosity PET protective film. Macromolecular polyols are vacuum dehydrated at 100-120°C for 1-5h, and then cooled to 60-80°C; then adding isocyanate, organic Solvent and catalyst, react at constant temperature at 500-1500r / min for 2-6h; add chain extender for chain extension reaction for 1-5h, cool to 30-50°C; then add salt-forming agent and deionized water, at 1000-3000r Under the condition of high-speed shearing and dispersion for 0.5‑2h per minute, a high-performance low-viscosity adhesive is obtained. The preparation process is simple and easy to operate, and it is suitable for industrial production. And the high-performance low-viscosity adhesive produced by the method provided by the present invention is used in the PET protective film, so that the PET protective film has the characteristics of low viscosity, easy to tear off, no residual glue, good adhesion, good high temperature resistance and excellent mechanical properties .

Owner:NINGBO KELAIEN NEW MATERIAL TECH CO LTD

Flame-retardant and fire-resistant marine cable insulating rubber and manufacturing method thereof

ActiveCN103642130BIncrease working temperatureIncrease profitRubber insulatorsInsulated cablesRubber materialVulcanization

The invention discloses a flame-retardant and fire-resistant cable insulation rubber for ships and a production method therefor. The raw materials are 20 parts of ethylene propylene diene monomer rubber 4045M, 0.5-0.6 part of vulcanizing agent DCP, 0.2-0.3 part of co-vulcanization agent TAC, 0.1-0.3 part of anti-aging agent MB, 0.1-0.3 part of anti-aging agent RD, 0.1-0.2 part of coupling agent A-172, 15-20 parts of aluminum hydroxide, 3-6 parts of ceramic glass powder, 1-1.5 parts of plasticizer No 1000 steam cylinder oil, 6-8 parts of fine talcum powder, 4-7 parts of reinforcing agent hydrated silica, and 5-8 parts of reinforcing agent calcined pottery clay. First, ethylene propylene diene monomer rubber 4045M is subjected to mixing for 1-1.5min, then the anti-aging agents, the coupling agent, aluminum hydroxide, the ceramic glass powder, the plasticizer, talcum powder and the reinforcing agents are added in order and after the above mixture is subjected to mixing for 7-8min, the mixture is unloaded and aired for above 24h; then the above rubber material is subjected to 2-3min, and the vulcanizing agent and the co-vulcanization agent are added in the last 20 seconds, the material after mixing is loaded in an open mill for thin-pass, after triangular packaging and square packaging are performed, sheets are obtained. The insulation rubber has simple production technology, low cost, small external diameter and light weight, is flexible and easy to bend, and is convenient for construction and installation.

Owner:嘉兴君宏汽车配件有限公司

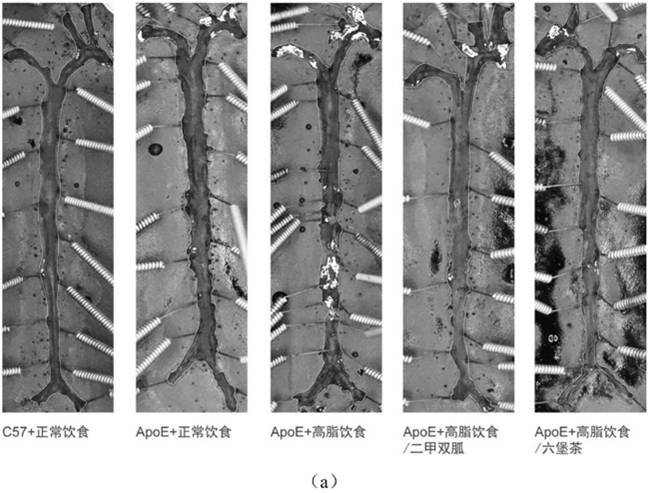

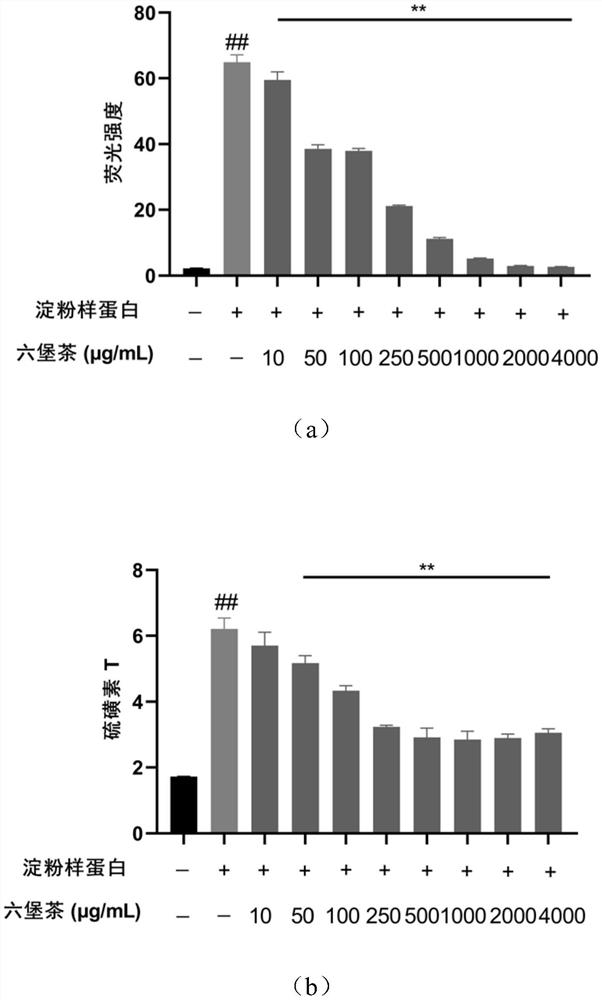

Application of Liupao tea in preparing functional products for preventing and treating amyloid protein diseases

PendingCN113812625AGood inhibitory effectInhibition formationAntinoxious agentsFood ingredient functionsAmyloidBiotechnology

The invention discloses application of Liupao tea in preparing functional products for preventing and treating amyloid protein diseases, the Liupao tea is prepared by adding Liupao tea dry powder, a Liupao tea hot water extract or a concentrate thereof into the functional products. According to the application of the Liupao tea in preparation of the functional product for preventing and treating the amyloid protein diseases, the functional products are diversified, such as medicines, health-care products, foods or beverages; the forms of adding the Liupao tea into the functional products are diversified, such as direct addition of the Liupao tea, the extract obtained by crushing the Liupao tea or extracting the Liupao tea with hot water, the concentrate obtained by extracting the Liupao tea and the like; and the functional products are wide in application field and simple in processing technology.

Owner:HUNAN AGRICULTURAL UNIV

Non-crosslinked EVA (ethylene-vinyl-acetate) rubber film for packaging thin-film solar cells and manufacturing method thereof

ActiveCN103555214BHigh melting pointHigh strengthNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAntioxidant

The invention discloses a non-crosslinked EVA (ethylene-vinyl-acetate) rubber film for packaging thin-film solar cells, which is characterized in that the rubber film is prepared from the following raw materials in percentage by weight: 97.44-98.55% of ethylene-vinyl acetate copolymers, 1.0-1.5% of maleic anhydride, 0.2-0.5% of a silane coupling agent, 0.1-0.2% of a light stabilizer, 0.05-0.06% of dicumyl peroxide, and 0.1-0.3% of an antioxidant; and the vinyl acetate content of the ethylene-vinyl acetate copolymers is 5-15%. The invention also provides a manufacturing method of the non-crosslinked EVA rubber film for packaging thin-film solar cells. The non-crosslinked EVA rubber film for packaging thin-film solar cells disclosed by the invention is high in melting point, high in strength, low in liquidity and strong in cohesive force, and kept in a thermoplastic state; the continuous packaging production of thin-film solar cell modules can be realized by using a rolling process, therefore, the non-crosslinked EVA rubber film is high in packaging efficiency and low in cost.

Owner:GUANGDONG ANDELI NEW MATERIALS CO LTD

A kind of resin for dripping film and its preparation method and application

ActiveCN107226891BInhibition of migration speedReduced homopolymerization tendencyPre irradiationFunctional monomer

The invention relates to resin for a dripping film, and a preparation method and application thereof, belonging to the technical field of agricultural materials. The objective of the invention is to overcome technical problems in preparation of dripping films with low cost and long dripping period. The resin for the dripping film in the invention is composed of, by weight, 81 to 95 parts of pre-irradiation polymer resin, 1 to 10 parts of grafted resin, 5 to 15 parts of functional monomers, 2 to 15 parts of a reverse graft, 1 to 5 parts of polyethylene-polystyrene resin and 2 to 3 parts of an electron-donating agent, wherein the weight parts of the pre-irradiation polymer resin, the grafted resin, the polyethylene-polystyrene resin and the reverse graft sum to 100. The invention further provides a preparation method for the resin and application of the resin as a dripping-film material. Results of an accelerated dripping experiment at 60 DEGC and an actual outdoor in-greenhouse experiment show that a dripping film prepared from the resin has a dripping period of 29 to 38 days and 12 to 14 months, respectively.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

High swing data line and preparation method thereof

ActiveCN112979891BHigh tensile strengthImprove toughnessInsulated cablesCable/conductor manufactureElastomerEngineering

The application relates to the technical field of communication transmission equipment, and specifically discloses a high swing data line and a preparation method thereof. The high-swing data line includes a conductive wire core covered with a high-swing TPE material, and the high-swing TPE material is made of raw materials including the following parts by weight: 20-40 parts of SEBS elastomer, 10 parts of polypropylene ‑20 parts, 5‑10 parts of calcium carbonate, 5‑10 parts of maleic anhydride, 2‑4 parts of grafting aid, 3‑5 parts of anti-wrinkle agent; its preparation method is: high swing TPE material is melt-extruded, and then Wrapped on the conductive wire core, weld the conductive wire core with the USB connector and the transmission connector, and then inject molding with high swing TPE material to obtain a high swing data cable. The high swing data line of the present application has good tensile strength, elongation at break and tear strength, and is not easy to crack; in addition, the preparation method of the present application is easy to operate, which helps to further reduce the breakage of the high swing data line.

Owner:SHENZHEN TARGE IND CO LTD

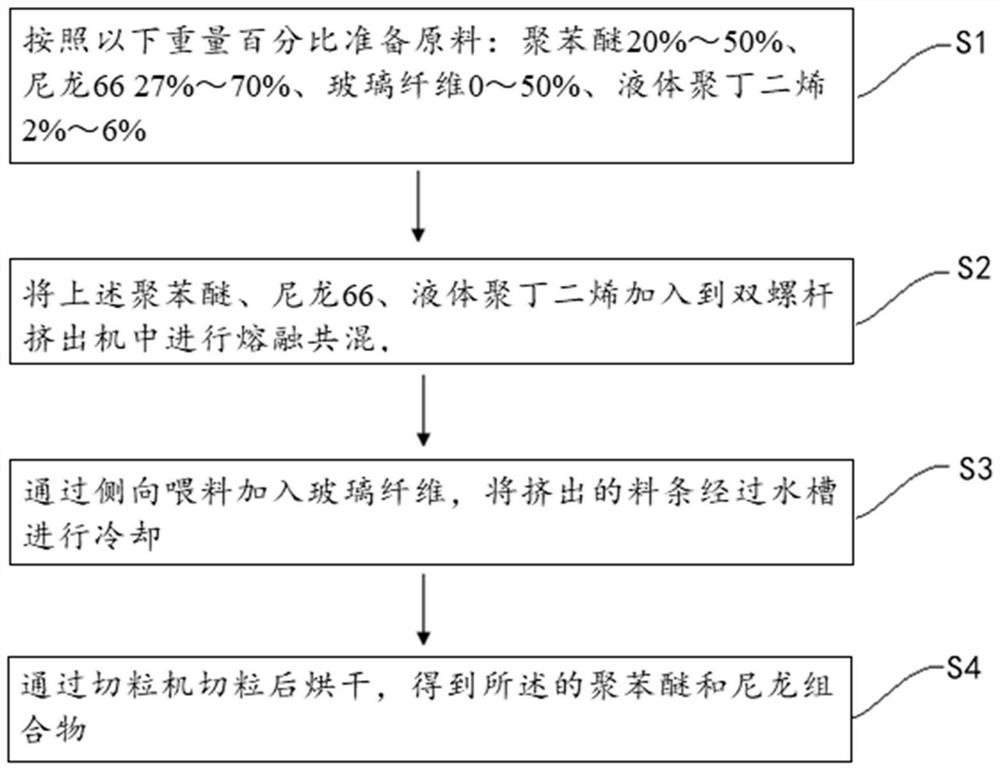

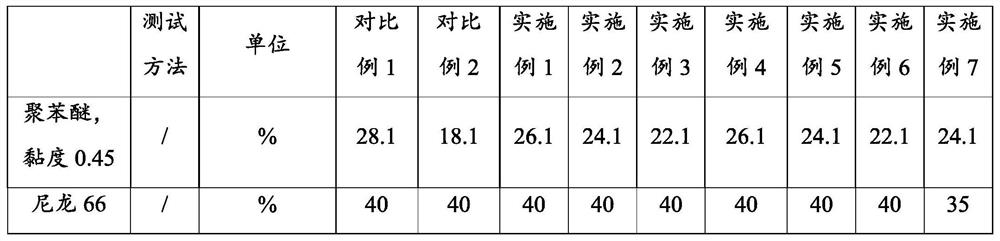

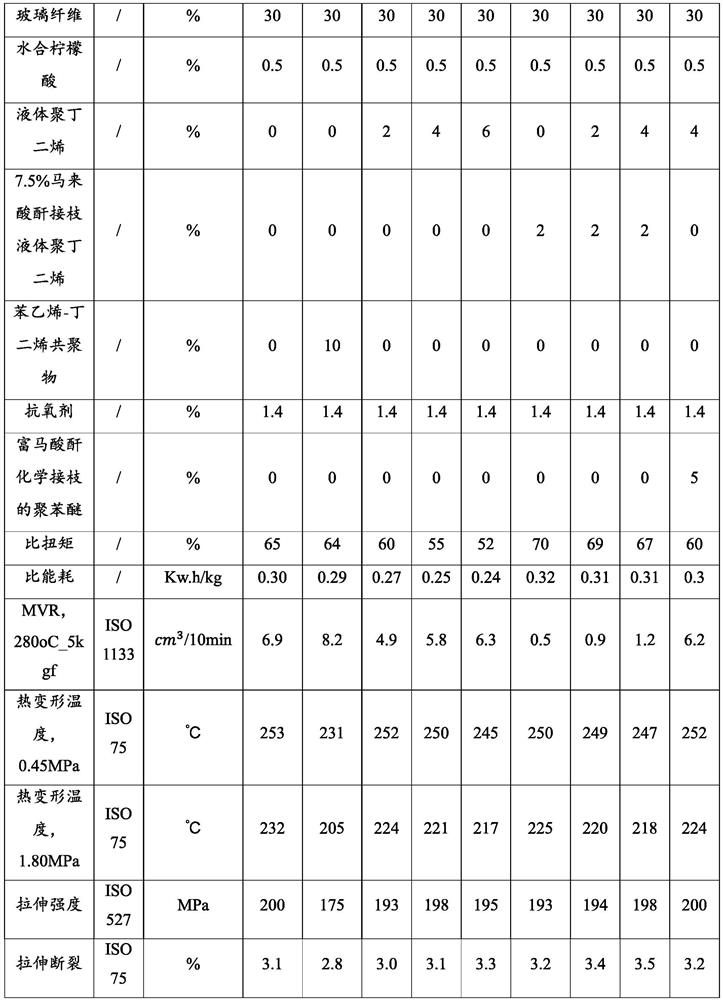

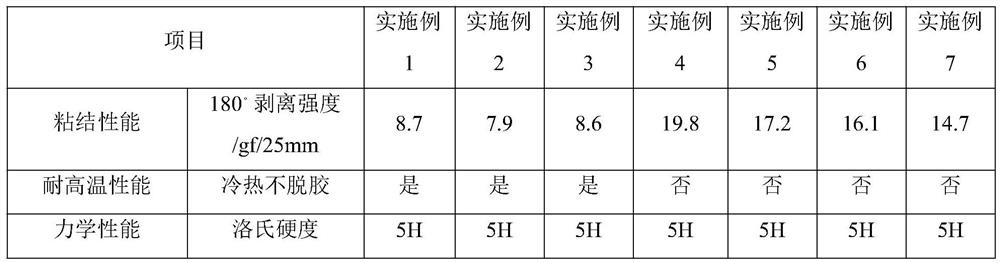

Polyphenyl ether and nylon composition and preparation method thereof

The invention discloses a polyphenyl ether and nylon composition and a preparation method thereof, and belongs to the technical field of high polymer materials. The composition comprises the following components in percentage by weight: 20%-50% of polyphenyl ether, 27%-70% of nylon 66, 0-50% of glass fiber and 2%-6% of liquid polybutadiene. The liquid polybutadiene is used for carrying out blending modification on polyphenyl ether and nylon, on one hand, the polyphenyl ether and the nylon can be toughened simultaneously, so that the polyphenyl ether and the nylon can still keep a good toughening effect at low temperature, and the low-temperature toughness and the chemical stress cracking resistance of the composition are improved; on the one hand, the toughness of the polyphenyl ether and nylon composition is improved, and the heat resistance and flame retardance of the polyphenyl ether can be kept not to be reduced, so that the temperature application range of the modified polyphenyl ether is not limited.

Owner:JIANGSU BOILN PLASTICS CO LTD

A low-viscosity pet protective film for foam materials

ActiveCN108822757BSimple preparation processEasy to operateFilm/foil adhesivesPolymer sciencePtru catalyst

Owner:NINGBO KELAIEN NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com