Flame-retardant fireproof wire and cable material and preparation method thereof

A wire and cable material, flame-retardant and fire-resistant technology, used in circuits, electrical components, plastic/resin/wax insulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

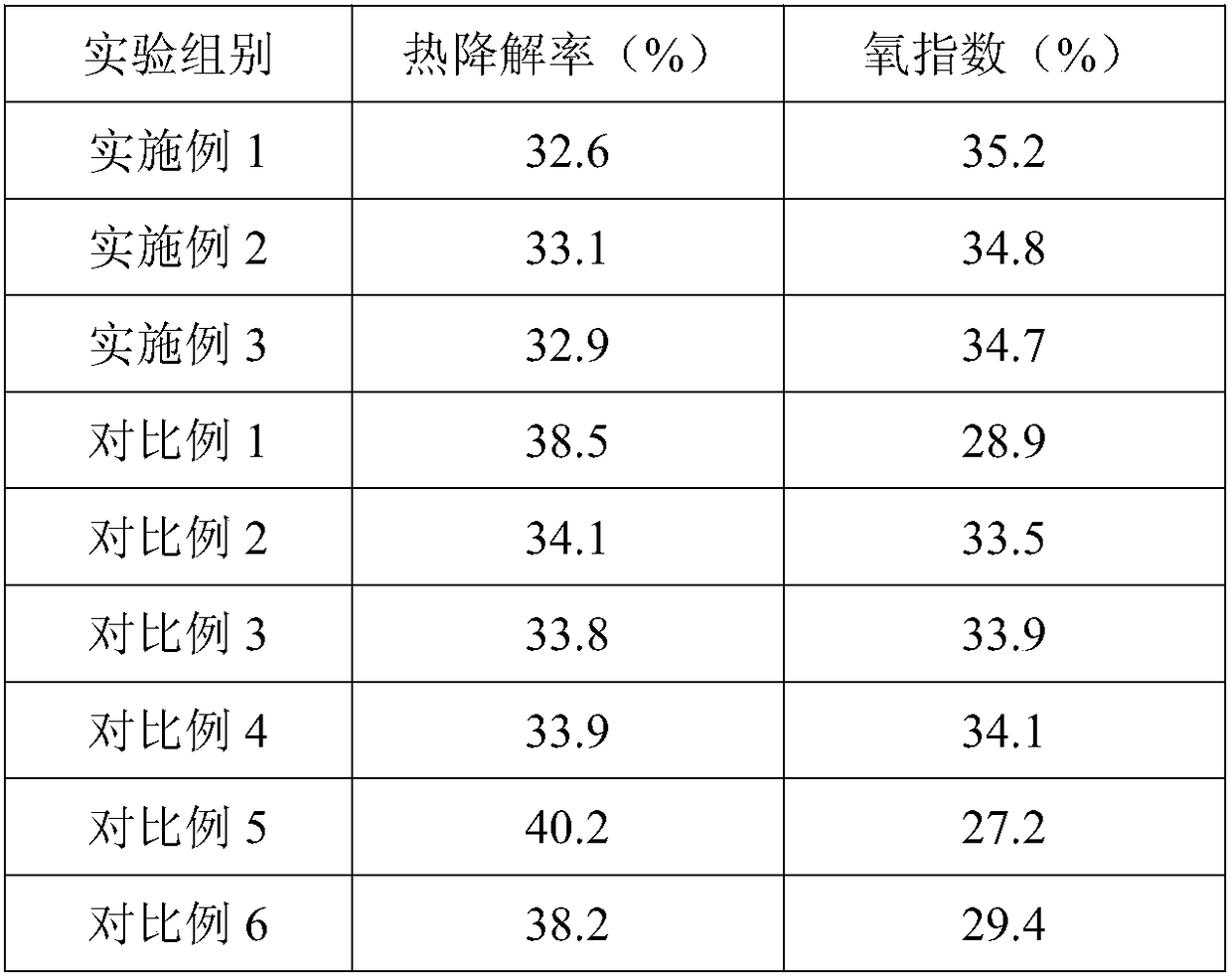

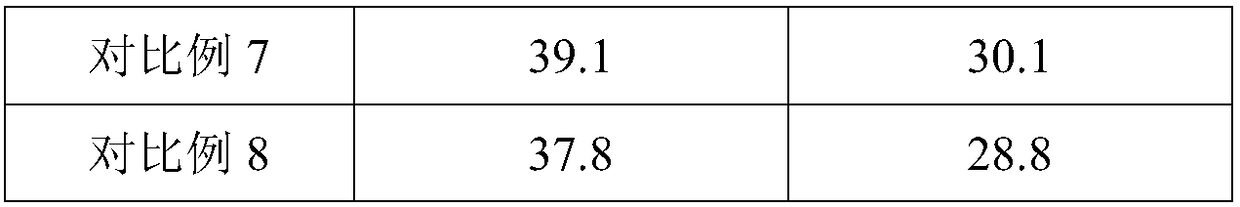

Examples

preparation example Construction

[0032] The preparation method of described flame-retardant fire-resistant wire and cable material, comprises the following steps:

[0033] S1: Weigh each raw material according to the weight of the constituent raw materials, put polypropylene resin, modified acrylic resin, methyl vinyl silicone rubber and anti-aging agent into the open mill, mix at 70-80°C for 5-7min, and mix Mixture A is obtained after uniformity;

[0034] S2: Add tributyl citrate, nano silicon dioxide, platinum hydroxide, polyimide, zinc stearate, white carbon black, silicone rubber coupling agent in parts by weight in the mixture A, at 80-100 Stir and knead at ℃ for 3-5 minutes to make the mixture uniform and obtain the mixture B;

[0035]S3: Add dicumyl peroxide and accelerator to the mixture B, continue to stir and knead for 2-3 minutes, use an extruder to plasticize and granulate, and control the temperature at 155-165°C to obtain a finished product.

Embodiment 1

[0037] The flame-retardant and fire-resistant wire and cable material includes the following components in parts by weight: 30 parts of polypropylene resin, 22 parts of modified acrylic resin, 20 parts of methyl vinyl silicone rubber, and 12 parts of tributyl citrate , 4.5 parts of nano silicon dioxide, 2.2 parts of dicumyl peroxide, 0.8 parts of platinum hydroxide, 1 part of polyimide, 6 parts of zinc stearate, 2 parts of vinyl triethoxysilane, white carbon black 25 parts, 0.3 parts of N-phenyl-β-naphthylamine, and 0.6 parts of triethanolamine.

[0038] The preparation method of described flame-retardant fire-resistant wire and cable material, comprises the following steps:

[0039] S1: Weigh each raw material according to the weight of the constituent raw materials, put polypropylene resin, modified acrylic resin, methyl vinyl silicone rubber and anti-aging agent into the open mill, mix at 75°C for 6 minutes, and mix well to obtain a mixed Material A;

[0040] S2: Add trib...

Embodiment 2

[0043] The flame-retardant and fire-resistant wire and cable material includes the following components in parts by weight: 33 parts of polypropylene resin, 15 parts of modified acrylic resin, 25 parts of methyl vinyl silicone rubber, and 10 parts of tributyl citrate , 6.8 parts of nano silicon dioxide, 3.6 parts of dicumyl peroxide, 1.2 parts of platinum hydroxide, 2 parts of polyimide, 2 parts of zinc stearate, 4 parts of vinyltrimethoxysilane, 20 parts of white carbon black parts, 0.4 parts of p-phenylenediamine, and 0.8 parts of triethylenediamine.

[0044] The preparation method of described flame-retardant fire-resistant wire and cable material, comprises the following steps:

[0045] S1: Weigh each raw material according to the weight of the constituent raw materials, put polypropylene resin, modified acrylic resin, methyl vinyl silicone rubber and anti-aging agent into the open mill, mix at 80°C for 7 minutes, and mix well to obtain a mixed Material A;

[0046] S2: A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com