Epoxy ethylene-octene copolymer composition and preparation method thereof

A technology of octene copolymer and epoxidized ethylene, which is applied in the field of epoxidized ethylene-octene copolymer composition and its preparation, and can solve the problems of complex reaction system, reduction of POE crosslinking degree, cumbersome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

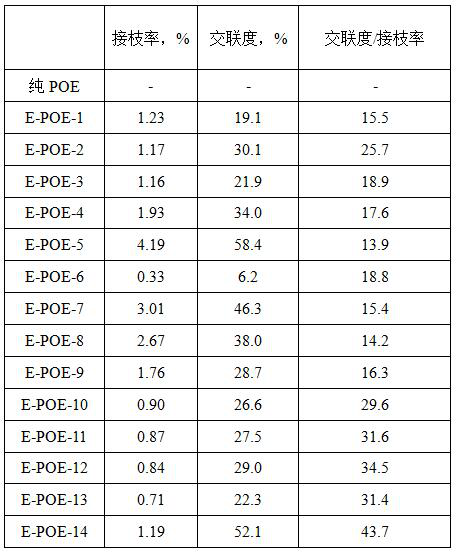

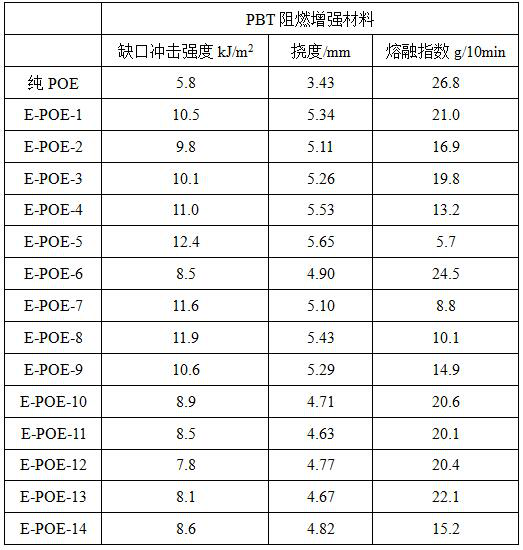

Examples

Embodiment 1

[0025] 94.0% POE resin (density 0.870 g / cm -3 , with a melt index of 5g / 10min), 3.0% GMA, 1.5% styrene, 0.3% 2,5-di-tert-butylperoxy-2,5-dimethylhexane (melting point below 8°C) and 1.2% Talc powder (particle size D90=5 microns) is mixed evenly in the high-speed mixer, and then fed into the twin-screw extruder through the feeding hopper for reactive extrusion. The length-to-diameter ratio of the twin-screw extruder used is L / D= 36. The extrusion temperatures of the first to ninth stages are: 60°C, 100°C, 190°C, 190°C, 190°C, 190°C, 200°C, 210°C, 170°C, the screw speed is 250 rpm, and the material E-POE-1 can be obtained after melt plasticization, extrusion, drying and pelletizing.

Embodiment 2

[0027] 94.0% POE resin (density 0.870 g / cm -3 , melt index is 5g / 10min), 3.0% GMA, 1.5% styrene, 0.3% dicumyl peroxide (DCP, melting point is 42°C) and 1.2% talc powder (particle size D90=5 microns) at high speed After the mixer is mixed evenly, it is fed into the twin-screw extruder through the feeding hopper for reactive extrusion. The length-to-diameter ratio of the twin-screw extruder used is L / D=36, and the extrusion temperatures of the first to ninth stages are respectively : 60°C, 100°C, 190°C, 190°C, 190°C, 190°C, 200°C, 210°C, 170°C, the screw speed is 250 rpm, the material is melted and plasticized, extruded, dried and pelletized E-POE-2 is available.

Embodiment 3

[0029] 94.0% POE resin (density 0.870 g / cm -3 , with a melt index of 5g / 10min), 3.0% GMA, 1.5% styrene, 0.3% 2,5-di-tert-butylperoxy-2,5-dimethylhexane (melting point below 8°C) and 1.2% Talc powder (particle size D90=20 microns) is uniformly mixed in the high-speed mixer, and then fed into the twin-screw extruder through the feeding hopper for reactive extrusion. The length-to-diameter ratio of the twin-screw extruder used is L / D= 36. The extrusion temperatures of the first to ninth stages are: 60°C, 100°C, 190°C, 190°C, 190°C, 190°C, 200°C, 210°C, 170°C, the screw speed is 250 rpm, and the material E-POE-3 can be obtained after melt plasticization, extrusion, drying and pelletizing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com