Flame-retardant and fire-resistant marine cable insulating rubber and manufacturing method thereof

An insulating rubber and marine cable technology, which is applied in the manufacture of flame-retardant and fire-resistant marine cable insulating rubber and the field of flame-retardant and fire-resistant marine cable insulating rubber. The problems of complex production process and unfavorable use in the ship's multi-acid-alkali corrosion environment have achieved the effect of low cross-linking density, excellent extrusion process performance, and inhibiting the aging of copper conductors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

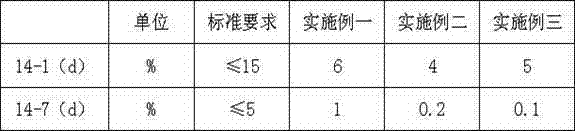

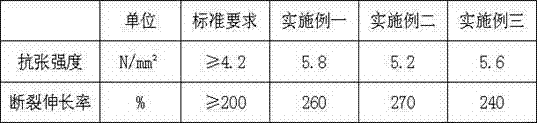

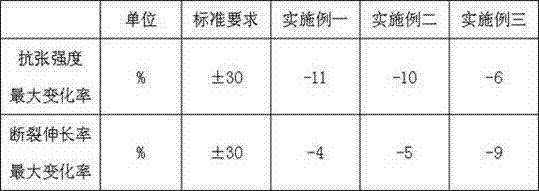

Examples

Embodiment 1

[0020] The manufacturing method of the flame-retardant and fire-resistant marine cable insulating rubber of the present invention comprises the following steps in turn: (1) Prepare raw materials according to the following components and weight content, EPDM rubber 4045M: 20 parts; vulcanizing agent dicumyl peroxide (Vulcanizing agent DCP): 0.5 parts; co-curing agent triallyl cyanurate (co-curing agent TAC): 0.2 parts; anti-aging agent 2-mercaptobenzimidazole (anti-aging agent MB): 0.1 parts; anti-aging Agent 2,2,4-trimethyl-1,2-dihydroquinoline polymer (antiaging agent RD): 0.1 part; coupling agent vinyl tris(β-methoxyethoxy)silane (silane coupling Joint agent A-172): 0.1 parts; flame retardant aluminum hydroxide (ie Al 2 o 3 ·3H 2 O hydrated alumina): 15 parts; refractory agent ceramic glass powder: 3 parts; plasticizer No. 1000 steam cylinder oil: 1 part; filler fine talcum powder: 6 parts; reinforcing agent hydrated silica: 4 parts; Reinforcing agent calcined clay: 5 par...

Embodiment 2

[0024] The manufacturing method of the flame-retardant and fire-resistant marine cable insulating rubber of the present invention comprises the following steps in turn: (1) Prepare raw materials according to the following components and weight content, EPDM rubber 4045M: 20 parts; vulcanizing agent dicumyl peroxide : 0.55 parts; co-vulcanizing agent triallyl cyanurate: 0.25 parts; anti-aging agent 2-mercaptobenzimidazole: 0.2 parts; anti-aging agent 2,2,4-trimethyl-1,2-di Hydroquinoline polymer: 0.2 parts; coupling agent vinyl tris (β-methoxyethoxy) silane: 0.15 parts; flame retardant aluminum hydroxide: 18 parts; refractory ceramic glass powder: 4 parts; Plasticizer No. 1000 steam cylinder oil: 1.2 parts; filler fine talcum powder: 7 parts; reinforcing agent hydrated silica: 5 parts; reinforcing agent calcined clay: 7 parts.

[0025] (2) First raise the temperature of the internal mixer to 170°C, then add EPDM rubber 4045M and mix for 1.2 minutes, then add the above-mentioned...

Embodiment 3

[0028]The manufacturing method of the flame-retardant and fire-resistant marine cable insulating rubber of the present invention comprises the following steps in turn: (1) Prepare raw materials according to the following components and weight content, EPDM rubber 4045M: 20 parts; vulcanizing agent dicumyl peroxide : 0.6 parts; co-vulcanizing agent triallyl cyanurate: 0.3 parts; anti-aging agent 2-mercaptobenzimidazole: 0.3 parts; anti-aging agent 2,2,4-trimethyl-1,2-di Hydroquinoline polymer: 0.3 parts; coupling agent vinyl tris (β-methoxyethoxy) silane: 0.2 parts; flame retardant aluminum hydroxide: 20 parts; refractory ceramic glass powder: 6 parts; Plasticizer No. 1000 steam cylinder oil: 1.5 parts; filler fine talcum powder: 8 parts; reinforcing agent hydrated silica: 7 parts; reinforcing agent calcined clay: 8 parts.

[0029] (2) First raise the temperature of the internal mixer to 180°C, then add EPDM rubber 4045M and mix for 1.5 minutes, then add the above-mentioned ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com