Polarizing plate manufacturing method

A manufacturing method and polarizer technology, which is applied in the field of polarizer manufacturing, can solve problems such as floating, failure to exert adhesiveness, and peeling film, and achieve the effects of improved production capacity, good appearance, and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

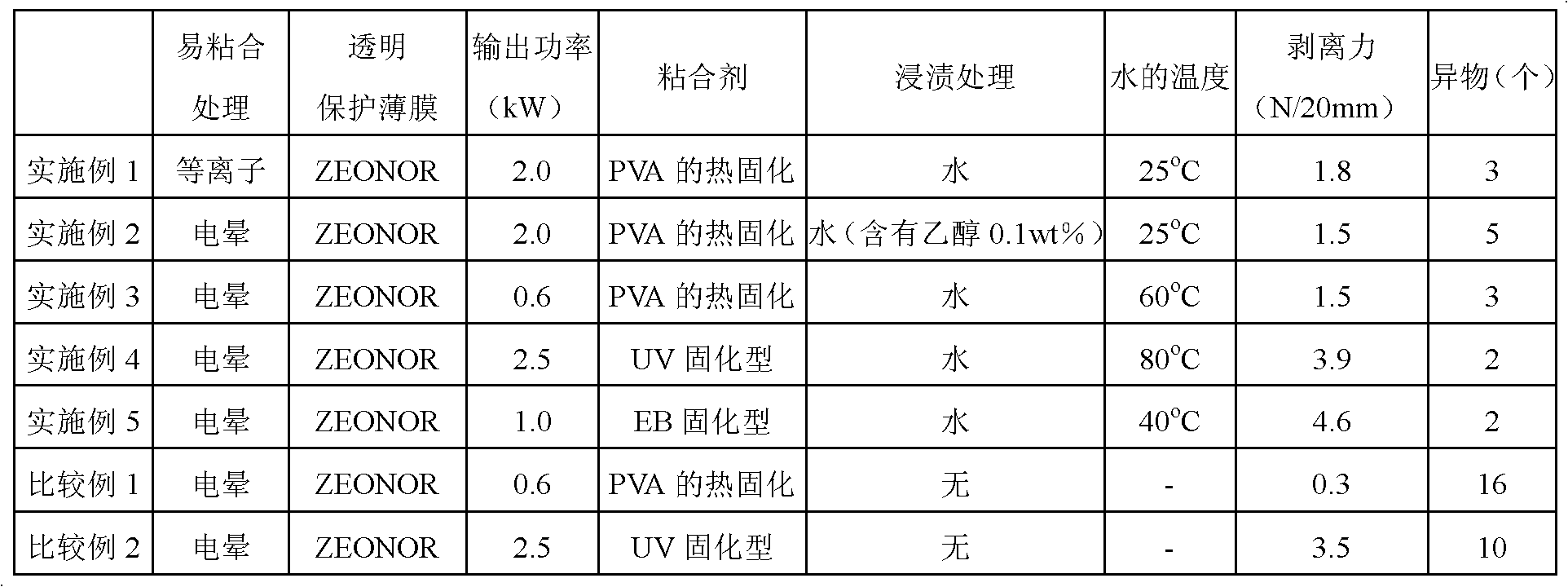

Examples

Embodiment 1

[0116]

[0117]A polyvinyl alcohol film having a thickness of 80 μm was immersed in a water bath at 30° C. to swell. Next, this polyvinyl alcohol was dipped in a 5% by weight (weight ratio: iodine / potassium iodide=1 / 10) iodine solution (liquid temperature: 30° C.) for 0.5 minutes to be dyed. Then immerse in the aqueous solution (liquid temperature is 30 ℃) that comprises the boric acid of 3 weight % and the potassium iodide of 2 weight % after 0.5 minute, then in the aqueous solution (liquid temperature is 60 ℃) that comprises the boric acid of 4 weight % and the potassium iodide of 3 weight % °C) for 1 minute, stretched to 6 times the initial length in the state after immersion. Then, it was immersed in 5 weight% potassium iodide aqueous solution (liquid temperature: 30 degreeC) for 0.5 minute. Then, it was dried in an oven at 40° C. for 1 minute to obtain a polarizing film with a thickness of 30 μm. The moisture content of the polarizing film was 14% by weight.

[0118]...

Embodiment 2

[0133] In this example, in addition to performing corona discharge treatment as an easy-adhesion treatment to the norbornene-based resin film, and immersing it once in a water bath (aqueous solution containing 0.1% by weight of ethanol) for 30 seconds, using the same The same method as in Example 1 was used to manufacture the polarizing plate of this example. In addition, the conditions of the corona discharge treatment were 2.0 kW of corona output intensity|strength, and 18 m / min of linear velocity.

Embodiment 3

[0135] In this example, except that the conditions of the corona discharge treatment on the norbornene-based resin film were changed to a corona output intensity of 0.6 kW and a line speed of 13 m / min, and the water temperature during the dipping treatment was changed to 60°C Except that, the polarizing plate of this example was produced similarly to Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com