Method for preparing modified polyacrylonitrile ion exchange fibers with electrostatic spinning method

A technology of electrospinning and modified ions, applied in separation methods, rayon manufacturing, fiber chemical characteristics, etc., can solve problems such as high bulkiness, poor uniformity, and low functional reaction efficiency, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

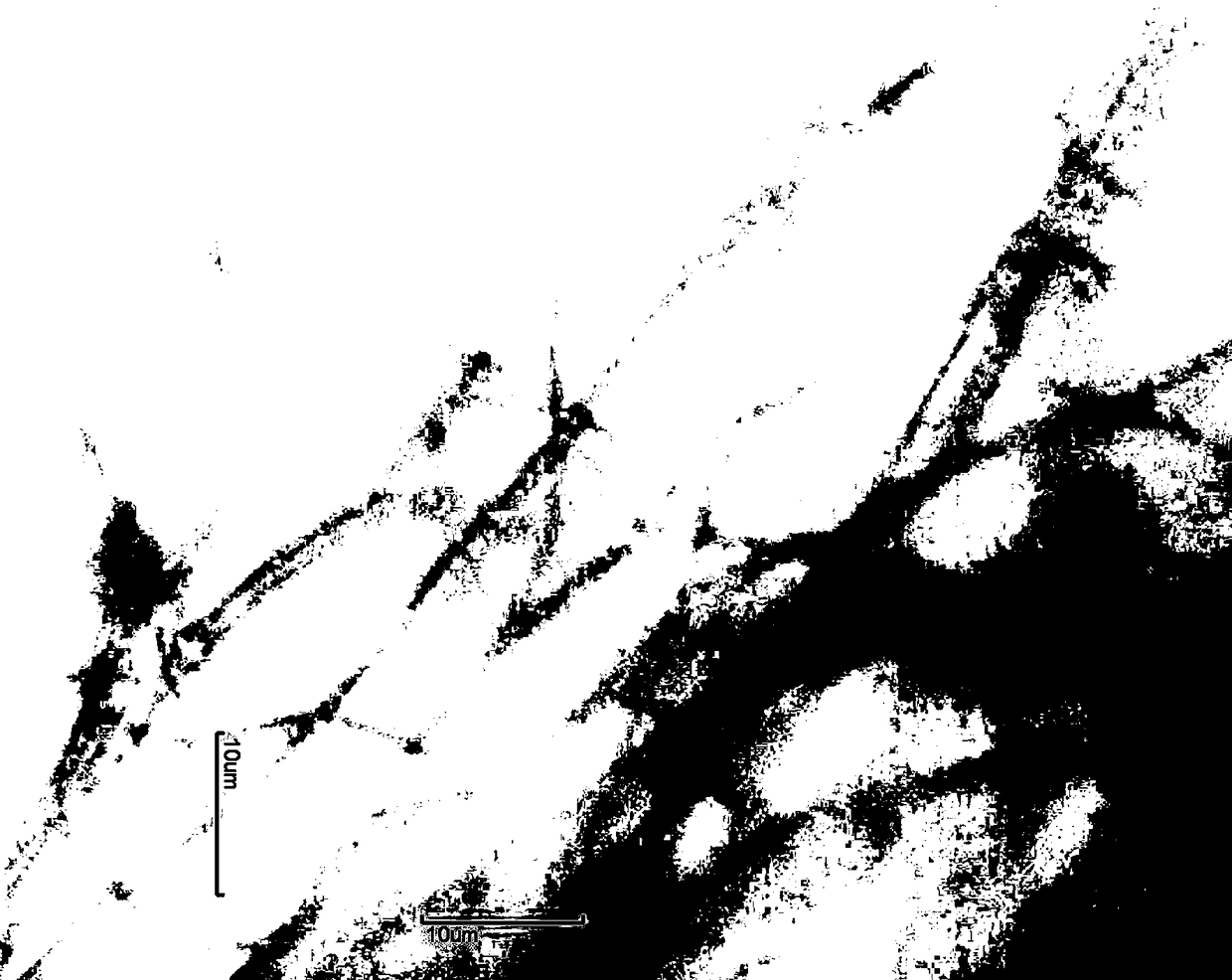

Image

Examples

Embodiment 1

[0014] (1) Preparation of modified polyacrylonitrile electrospinning solution: dissolve polyacrylonitrile in dimethylformamide to prepare a polyacrylonitrile solution with a mass percentage of 5%, stir at room temperature, and add triethylenetetramine (The mass ratio of polyacrylonitrile to triethylenetetramine is 1:5), heated up to 100°C and reacted for 120 minutes, then cooled down and discharged to obtain a modified polyacrylonitrile electrospinning solution.

[0015] (2) Electrospinning step: Add the electrospinning solution prepared in step (1) into the storage tank connected to the electrospinning nozzle, control the spinning voltage to 30KV, and the spinning distance to 20cm to carry out electrospinning, and the static receiving Electrospun ion exchange fibers were collected by the device. After vacuum drying, the exchange capacity of the modified polyacrylonitrile electrospun fiber reached 4.9 mmol / g.

Embodiment 2

[0017] (1) Preparation of modified polyacrylonitrile electrospinning solution: dissolve polyacrylonitrile in dimethylformamide to prepare a polyacrylonitrile solution with a mass percentage of 6%, stir at room temperature, and add diethylenetriamine (The mass ratio of polyacrylonitrile to diethylenetriamine is 1:4), heated up to 100°C and reacted for 120 minutes, cooled down and discharged to prepare modified polyacrylonitrile electrospinning solution.

[0018] (2) Electrospinning step: Add the electrospinning solution prepared in step (1) into the storage tank connected to the electrospinning nozzle, control the spinning voltage to 30KV, and the spinning distance to 20cm to carry out electrospinning, and the static receiving Electrospun ion exchange fibers were collected by the device. After vacuum drying, the exchange capacity of the modified polyacrylonitrile electrospun fiber reaches 5.6 mmol / g.

Embodiment 3

[0020] (1) Preparation of modified polyacrylonitrile electrospinning solution: dissolve polyacrylonitrile in dimethylformamide to prepare a polyacrylonitrile solution with a mass percentage of 8%, stir at room temperature, and add triethylenetetramine (The mass ratio of polyacrylonitrile to triethylenetetramine is 1:3), heated up to 110°C and reacted for 100 minutes, then cooled down and discharged to obtain a modified polyacrylonitrile electrospinning solution.

[0021] (2) Electrospinning step: Add the electrospinning solution prepared in step (1) into the storage tank connected to the electrospinning nozzle, control the spinning voltage to 25KV, and the spinning distance to 20cm, and carry out electrospinning, and the static receiving Electrospun ion exchange fibers were collected by the device. After vacuum drying, the exchange capacity of the modified polyacrylonitrile electrospun fiber reaches 4.7mmol / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com