Polyphenyl ether and nylon composition and preparation method thereof

A technology of polyphenylene ether and composition, which is applied in the field of polyphenylene ether and nylon composition and its preparation, can solve the problem of limiting the temperature application range of modified polyphenylene ether, reducing the heat distortion temperature and relative temperature index of materials, and the loss of polyphenylene ether. Ether heat resistance and flame retardant properties, etc., to improve toughness, improve hydrolysis resistance, and reduce water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

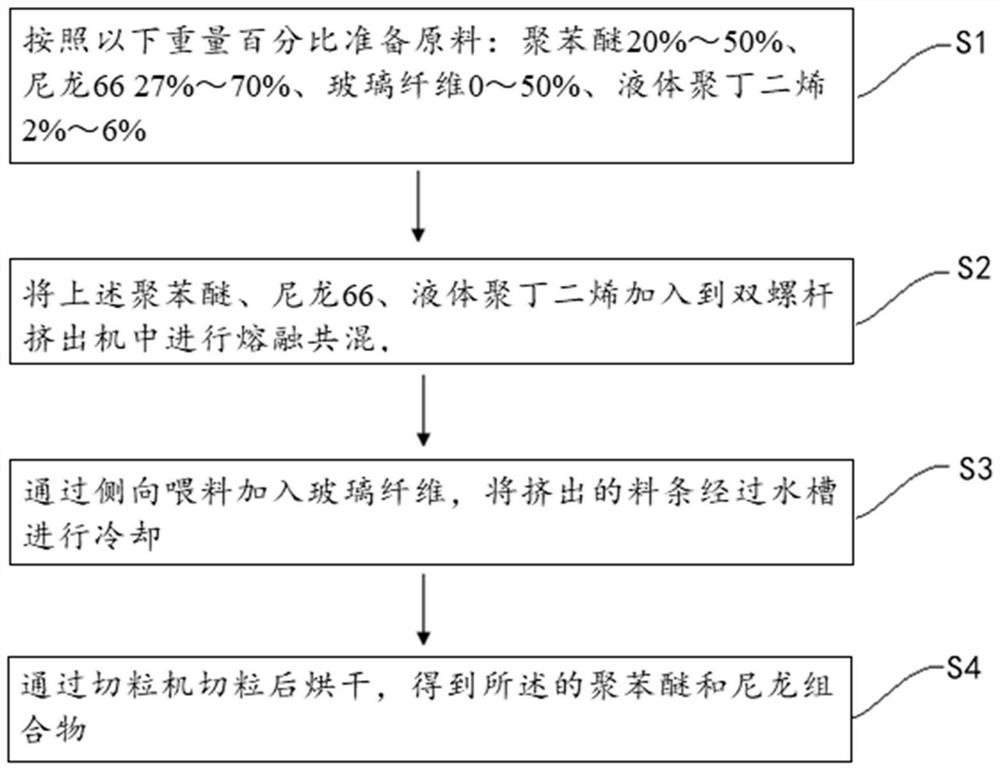

[0067] Corresponding to the above polyphenylene ether and nylon composition, the embodiment of the present invention also provides a preparation method of polyphenylene ether and nylon composition, refer to figure 1 As shown, the method includes the following steps:

[0068] S1: Prepare raw materials according to the following weight percentages: polyphenylene ether 20%-50%, nylon 6627%-70%, glass fiber 0-50%, liquid polybutadiene 2%-6%;

[0069] S2: Add the above-mentioned polyphenylene ether, nylon 66, and liquid polybutadiene into a twin-screw extruder for melt blending. The barrel temperature of the twin-screw extruder is The screw speed of the machine is 200-900RPM. Preferably, the barrel temperature is 290°C, the screw speed is 450RPM, and the production capacity is 50kg / hr;

[0070] S3: Add glass fiber through side feeding, and cool the extruded strip through the water tank;

[0071] S4: pelletizing by a pelletizer and then drying to obtain the polyphenylene ether an...

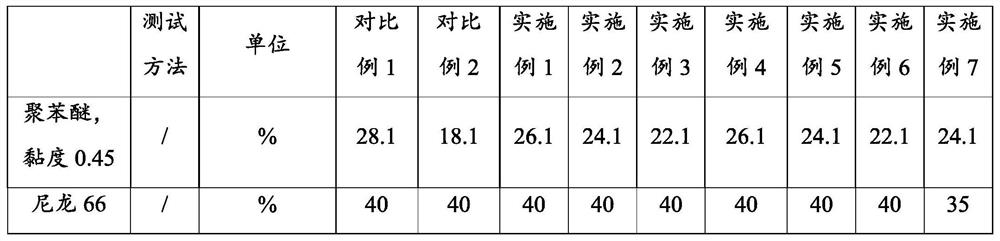

Embodiment 1

[0080] A polyphenylene ether and nylon composition, calculated by weight percentage, the components of the composition include:

[0081] 26.1% polyphenylene ether, 6640% nylon, 30% glass fiber, 0.5% citric acid, 2% liquid polybutadiene, 1.4% antioxidant, among which citric acid is hydrated citric acid, and the viscosity of polyphenylene ether is 0.45dL / g.

Embodiment 2

[0083] A polyphenylene ether and nylon composition, calculated by weight percentage, the components of the composition include:

[0084] 24.1% polyphenylene ether, 6640% nylon, 30% glass fiber, 0.5% citric acid, 4% liquid polybutadiene, 1.4% antioxidant, among which citric acid is hydrated citric acid, and the viscosity of polyphenylene ether is 0.45dL / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com