Preparation method of konjak-glucomannan-based super-water-absorbent granules

A glucomannan-based, water-absorbing particle technology, applied in the field of super water-absorbing agents, can solve the problems of uneven particle size, poor particle size, etc., and achieve the effects of reducing interfacial tension, prolonging stability, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method of konjac glucomannan-based super water-absorbing particles, comprising the following operations:

[0028] (1) konjac fine powder is placed in warm water and stirred to make it fully swell to obtain konjac fine powder liquid;

[0029] (2) add hexanaphthene and liquid paraffin mixed oil phase and Span 80 that are formed in the konjac fine powder liquid, and stir, obtain the first mixed liquor; In the mixed oil phase, hexanaphthene and liquid paraffin volume ratio are 1: 3~3:1, the volume ratio of Span 80 to mixed oil phase is 1:20~1:50;

[0030] (3) Add ammonium persulfate to the first mixed solution, and stir evenly to obtain the second mixed solution;

[0031] (4) Add acrylic acid and N-N methylenebisacrylamide neutralized with sodium hydroxide to the second mixed liquid, stir and raise the temperature to 60-85°C to fully react;

[0032] (5) Stop stirring the reaction solution and cool it to room temperature. After the reaction solution is allowe...

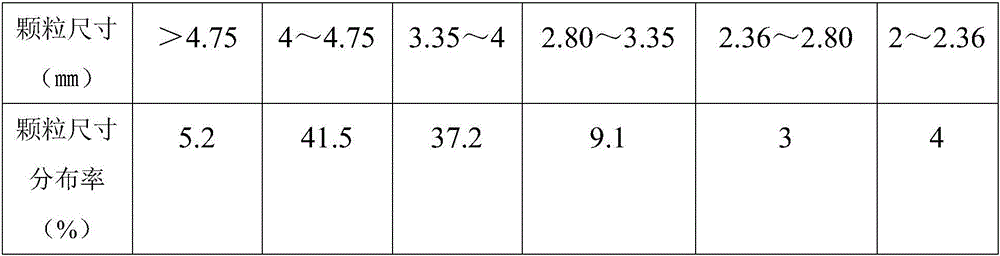

Embodiment 1

[0035] A preparation method of konjac glucomannan-based super water-absorbing particles, comprising the following operations:

[0036] (1) Take konjac fine powder with a mass fraction of 1% and place it in 40°C pure water for insulation and stirring to make it fully swell;

[0037] (2) in step (1) the konjac fine powder solution, add the mixed organic phase that the hexanaphthene of 2 times volume and liquid paraffin form and Span 80, wherein hexanaphthene and liquid paraffin volume ratio are 1:3, division The total volume ratio of class 80 mixed with cyclohexane and liquid paraffin in the organic phase is 1:50, and stirred evenly;

[0038] (3) adding mass fraction to the solution stirred in step (2) is 0.06% ammonium persulfate, and stir evenly;

[0039] (4) To the solution obtained in step (3), add acrylic acid and 0.01% N-N methylenebisacrylamide with a mass fraction of 7% neutralized with sodium hydroxide, stir at a stirring speed of 400r / min and Raise the temperature to...

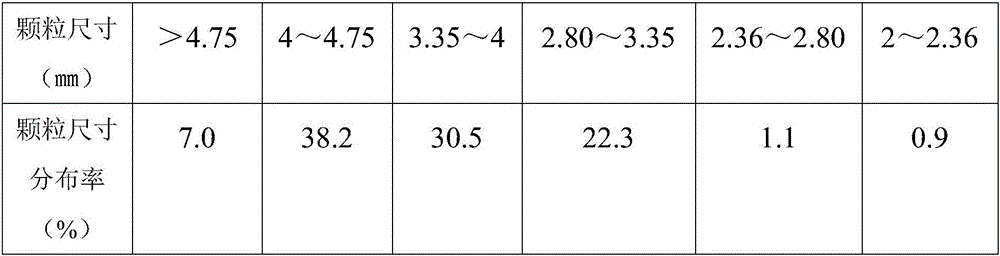

Embodiment 2

[0048] A preparation method of konjac glucomannan-based super water-absorbing particles, comprising the following operations:

[0049] (1) Take konjac fine powder with a mass fraction of 2% and place it in 40°C pure water for insulation and stirring to make it fully swell;

[0050] (2) in step (1) konjac fine powder solution, add the mixed organic phase that the hexanaphthene of 1.5 times volume and liquid paraffin form and Span 80, wherein hexanaphthene and liquid paraffin volume ratio are 2:3, division The total volume ratio of the volume of class 80 mixed with cyclohexane and liquid paraffin organic phase is 1:40, and stir evenly;

[0051] (3) adding mass fraction to the stirred solution of step (2) is 0.12% ammonium persulfate, and stir evenly;

[0052] (4) To the solution obtained in step (3), add acrylic acid and 0.02% N-N methylenebisacrylamide with a mass fraction of 8% neutralized with sodium hydroxide, stir at a stirring speed of 500r / min and Raise the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com