Prepn. of maleic anhydride grafted ethylene-alpha-octylene copolymers

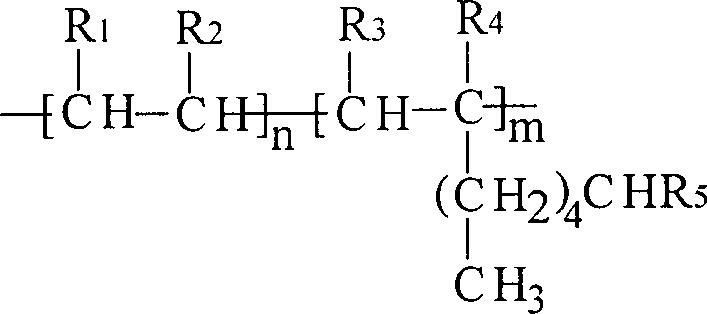

A technology of octene copolymer and maleic anhydride is applied in the field of preparation of maleic anhydride grafted ethylene-α-octene copolymer, which can solve the problems of affecting application, low product grafting rate and the like, and achieve high grafting rate , the effect of inhibiting the cross-linking reaction and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

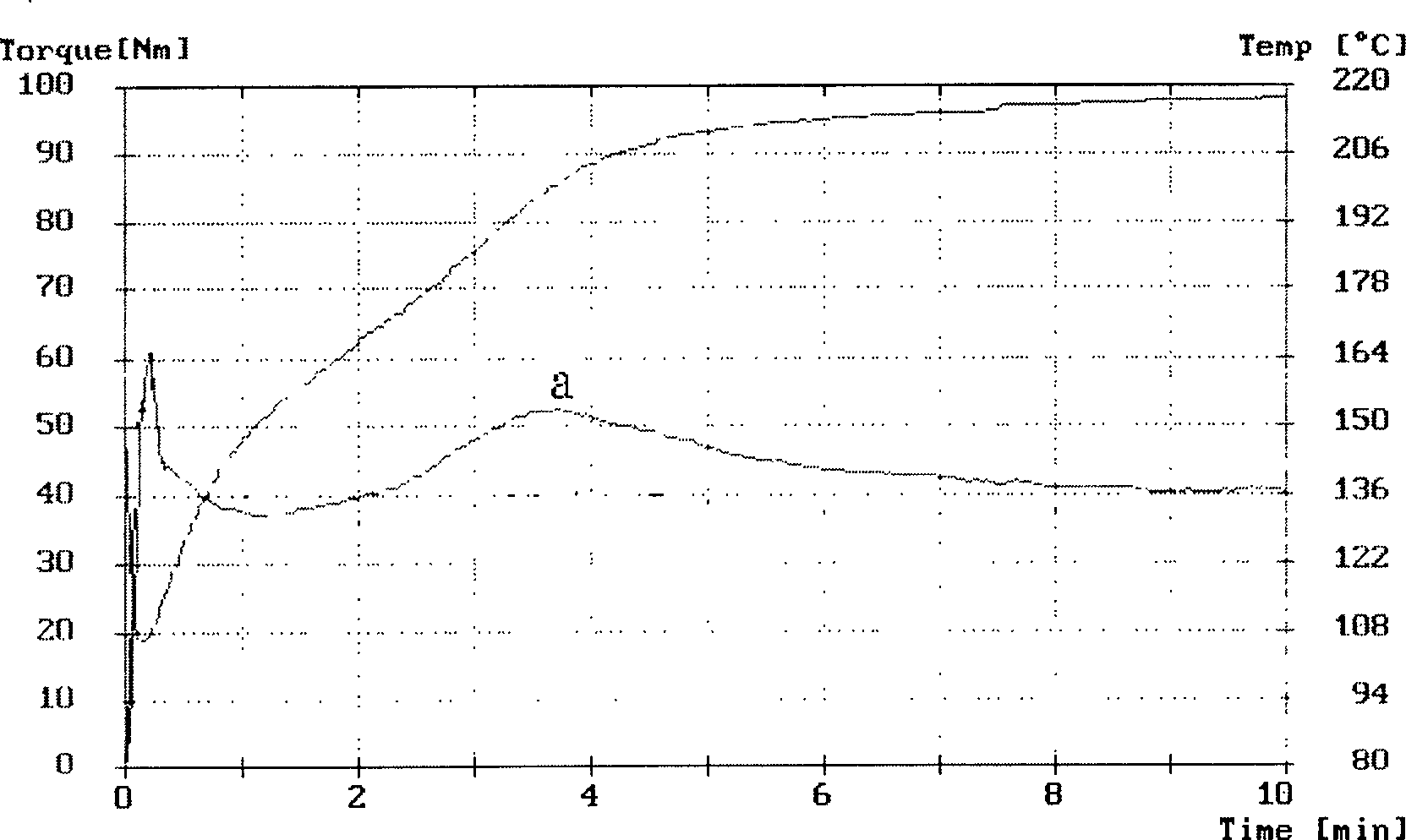

[0070] 50g ethylene-α-octene copolymer, 0.75g dicumyl peroxide (DCP), 5g maleic anhydride premixed, then join in internal mixer (Germany BRABENDER PL2100 torque rheometer), initial temperature setting Set at 150°C, set the rotation speed at 60r / min, and set the reaction time at 10 minutes. The results are shown in Table 1.

Embodiment 2

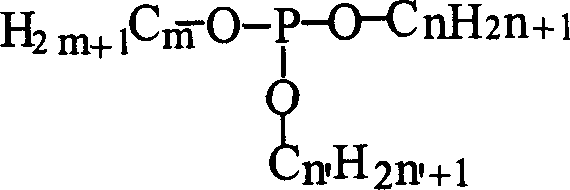

[0072] 50g ethylene-alpha-octene copolymer, 0.75g dicumyl peroxide (DCP), 5g maleic anhydride, 1.5g triphenyl phosphite are premixed, and then the homogeneously mixed material is added to a banbury mixer (Germany In the BRABENDER PL2100 torque rheometer), the initial temperature is set to 150° C., the rotating speed is set to 60 r / min, and the reaction time is set to 10 minutes. The results are shown in Table 1.

Embodiment 3

[0076] 50g of ethylene-α-octene copolymer, 0.75g of dicumyl peroxide (DCP), 5g of maleic anhydride, and 1.5g of diphenyldecyl phosphite are pre-mixed, and then the uniformly mixed material is added to the banburying mixer In the machine (BRABENDER PL2100 torque rheometer in Germany), the initial temperature is set to 150° C., the rotating speed is set to 60 r / min, and the reaction time is set to 10 minutes. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com