A kind of high-performance low-viscosity preparation method for low-viscosity pet protective film

A protective film, high-performance technology, applied in the direction of adhesives, adhesive types, film/sheet release liners, etc., can solve the problems of unstable viscosity, residual glue residue, high temperature resistance, etc., and reduce the degree of crosslinking , Reduce activity, good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

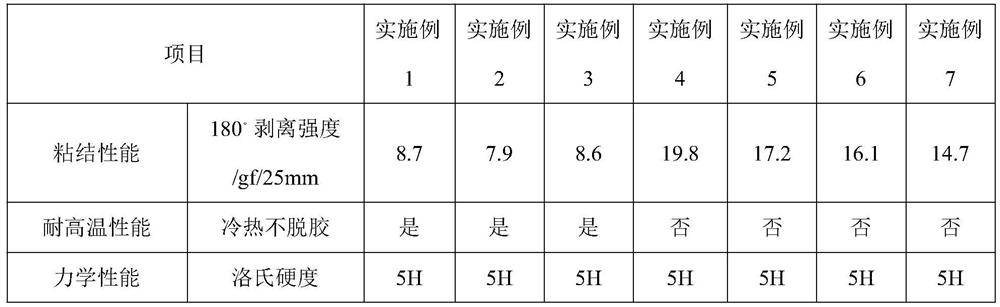

Examples

preparation example Construction

[0025] The chain extender plays an important role in the preparation of high-performance low-viscosity adhesives. The chain extender is acidic, and the acidic substance can inhibit the formation reaction of biuret, thereby inhibiting the cross-linking reaction, thereby reducing the degree of cross-linking and reducing the viscosity.

[0026] As a preferred solution, the salt-forming agent is preferably one or more of triethylamine, NaOH, KOH and ammonia water. The organic solvent is preferably one or more of acetone, butanone, N-methylpyrrolidone and N,N-dimethylformamide.

[0027] As a preferred version, the catalyst is prepared according to the following method: stir and heat methylimidazole and ethyl bromide with a molar ratio of 1:1 under the condition of 450-750r / min and heat up to 50-80°C for 6-18h, then use The catalyst was obtained by washing with ethyl acetate several times.

[0028] The catalyst plays a role in promoting the preparation of high-performance low-visco...

Embodiment 1

[0037] The low-viscosity PET protective film for foam materials of the present invention consists of a 50 μm PET base layer, a 5 μm low-viscosity intermediate layer, and a 20 μm protective layer.

[0038]The low-viscosity intermediate layer is formed by high-performance low-viscosity adhesive, which consists of 20 parts by weight of macromolecular polyol polyether polyol, 3 parts by weight of isocyanate toluene diisocyanate, 2 parts by weight of chain extender, and 0.5 parts by weight of salt Agent triethylamine, 4 parts by weight of catalyst, 10 parts by weight of organic solvent acetone and 100 parts by weight of deionized water, the specific preparation method is as follows:

[0039] (1) Vacuum dehydrate the macromolecular polyol at 100°C for 5 hours, then cool to 60°C;

[0040] (2) Add isocyanate, organic solvent and catalyst, and react at a constant temperature for 6 hours under the condition of 500r / min;

[0041] (3) Then add a chain extender for chain extension reactio...

Embodiment 2

[0049] The low-viscosity PET protective film for foam materials of the present invention consists of a 100 μm PET base layer, a 10 μm low-viscosity intermediate layer, and a 50 μm protective layer.

[0050] The low-viscosity middle layer is formed by high-performance low-viscosity adhesive, which is composed of 80 parts by weight of macromolecular polyol polyester polyol, 5 parts by weight of isocyanate 4,4'-diphenylmethane diisocyanate, 3 parts by weight of expanded Chain agent, 0.5-2 parts by weight of salt-forming agent ammonia water, 4-10 parts by weight of catalyst, 10 parts by weight of organic solvent N-methylpyrrolidone and 100 parts by weight of deionized water, the specific preparation method is as follows:

[0051] (1) Vacuum dehydrate the macromolecular polyol at 120°C for 2 hours, then cool to 80°C;

[0052] (2) Add isocyanate, organic solvent and catalyst, and react at a constant temperature for 2 hours under the condition of 1500r / min;

[0053] (3) Then add a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com